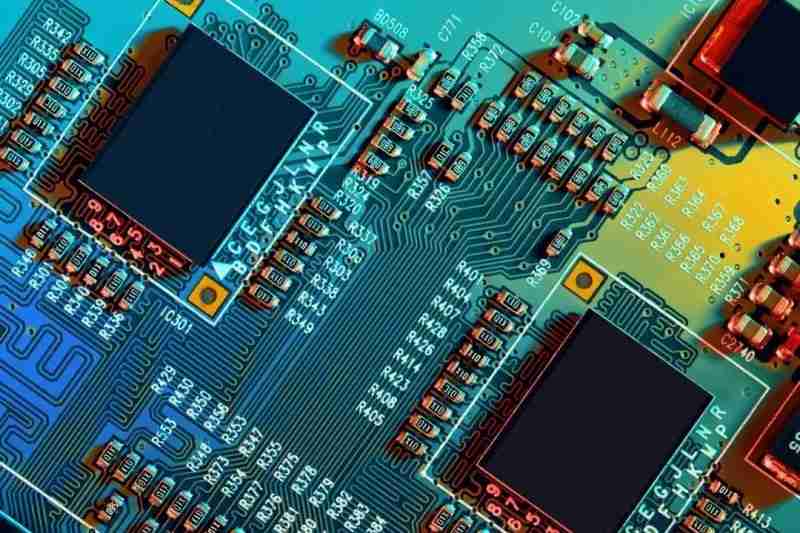

PCB board is one of the most common electronic components at present, almost all electronic products will use PCB board.

printed circuit board is widely used in electronics, computers, electrical appliances, mechanical equipment and other industries, it is the components of the support body, mainly used to connect components to provide electrical, among which the most common and widely used 4 and 6 layers of circuit boards, according to the industry application can choose different degrees of PCB board layer number.The printed circuit board is based on the insulating board, cut into a certain size, and at least one conductive graphic is attached on it, and there are holes (such as component holes, fastening holes, metallization holes, etc.), used to replace the chassis of the previous device electronic components, and realize the mutual connection between the electronic components. Because the board is produced by electronic printing, it is called "printed" circuit board. The customary term "printed circuit board" as "printed circuit" is incorrect because there are no "printed components" on a printed board, only wiring.

PCB circuit board is an important electronic component, is the support body of electronic components. The automatic soldering machine provides technical support for the soldering of PCB circuit board, so that the development of electronic components can progress. However, the corrosion of the PBC circuit board has been plagued by automatic soldering business.

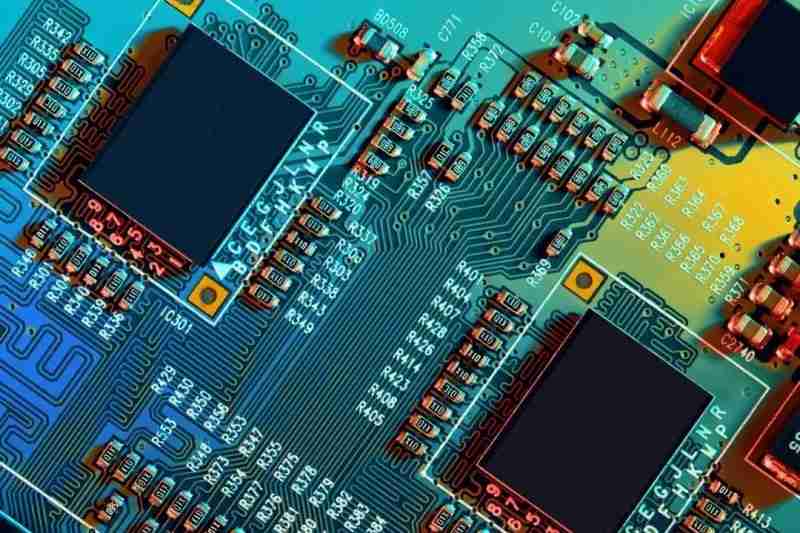

PCB board corrosion method:

With a corrosive liquid, it can generally corrode multiple circuit boards at a time. Corrosive liquid is generally configured with ferric chloride and water. Ferric chloride is a soil yellow solid, which is easy to absorb water in the air, so it should be sealed and preserved.

Corrosion steps of PCB circuit board:

After the corrosion solution is configured, the corrosion starts from the edge of the PCB circuit board. When the copper foil not covered with toner is corroded, the circuit board should be taken out in time to avoid the corrosion of useful lines after the toner falls off.

After the corroded circuit board is removed, it is necessary to rinse with water and sand the toner with fine sandpaper. Then dry, exposing the shiny copper foil that completes the circuit board.

Finally, in order to better preserve the circuit board, the polished circuit board is usually coated with rosin solution, which can not only aid welding, but also prevent oxidation.

PCB board corrosion is what kind of process:

Corrosion liquid is usually made of ferric chloride and water configuration, ferric chloride is a yellow solid, also easy to absorb water in the air, so it should be sealed. Configuration of ferric chloride solution is generally used 40% ferric chloride and 60% water, of course, ferric chloride more, or with warm water (not hot water, in case of paint off) can make the reaction faster attention ferric chloride has a certain corrosive, try not to touch the skin and clothes, reaction container with cheap plastic basin, put the circuit board is good.

Corrosion PCB boardsfrom the edges. When the unpainted copper foil has been corroded, the PCB boards should be removed in time to prevent the paint from peeling and corroding useful lines. Rinse with clean water and scrape off the paint with bamboo (when the paint comes out of the liquid, it is easier to remove). If it's not easy to scrape, just run it under hot water. Then dry it off, sand it clean, reveal shiny copper foil, and you have a printed circuit board. To preserve the results, polished PCB boards are often coated with rosin solution, both to aid welding and to prevent oxidation