Circuit board manufacturer explains high-frequency microwave board

Circuit board manufacturer, circuit board design, PCBA processing manufacturer explain to you the circuit board manufacturer's explanation of high-frequency microwave board

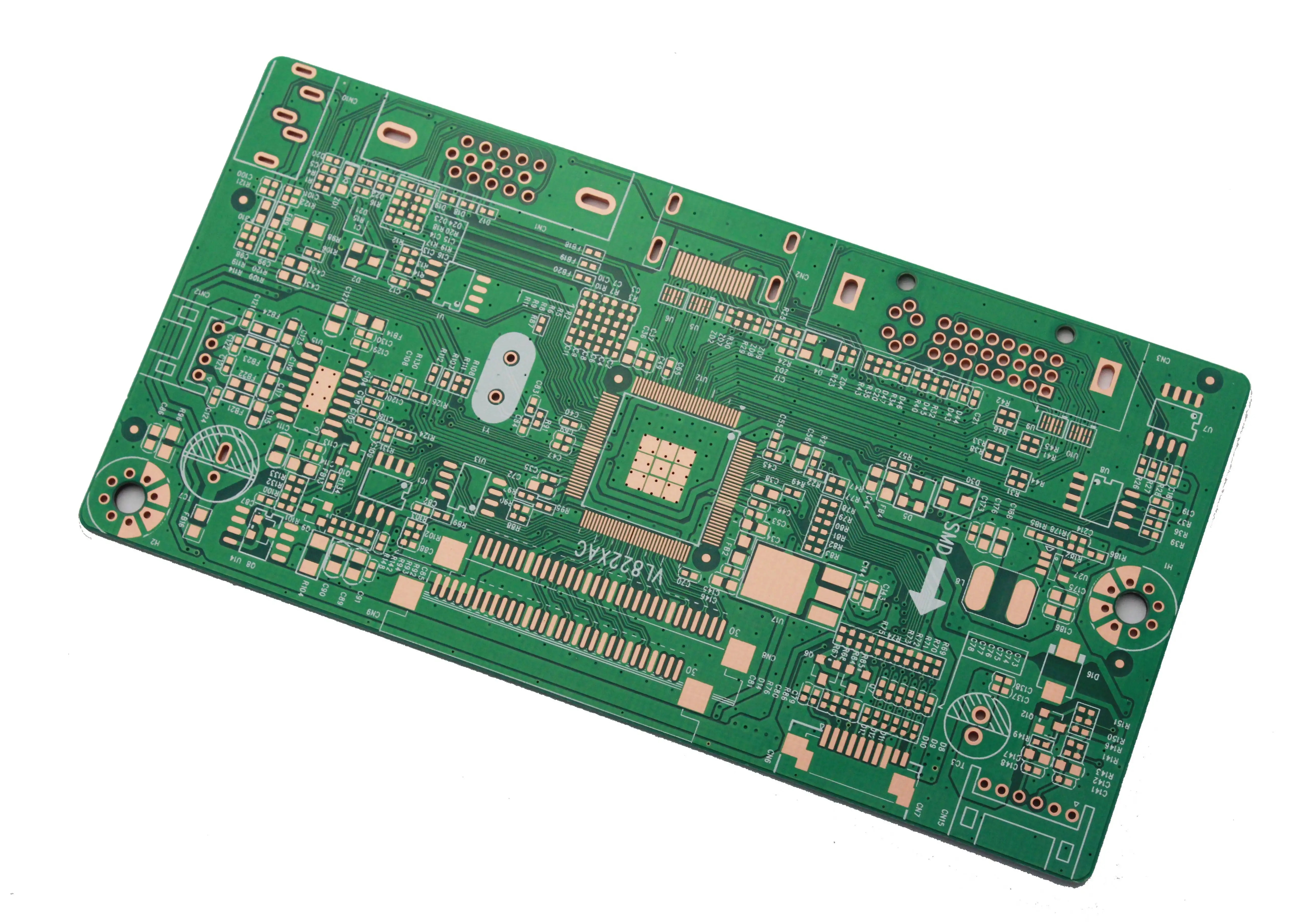

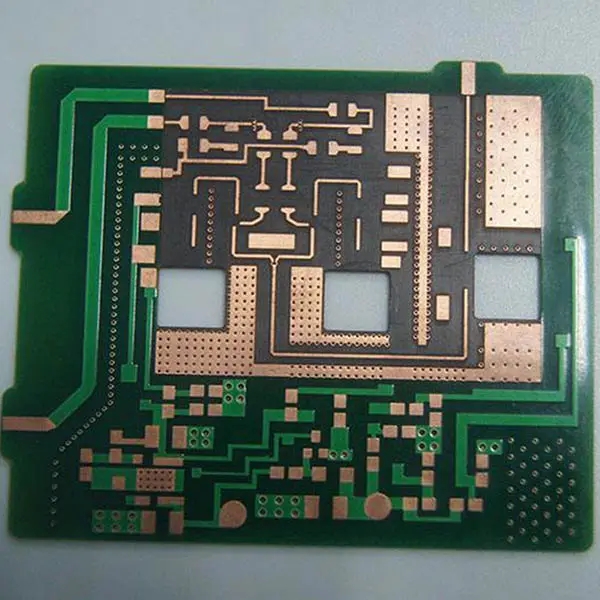

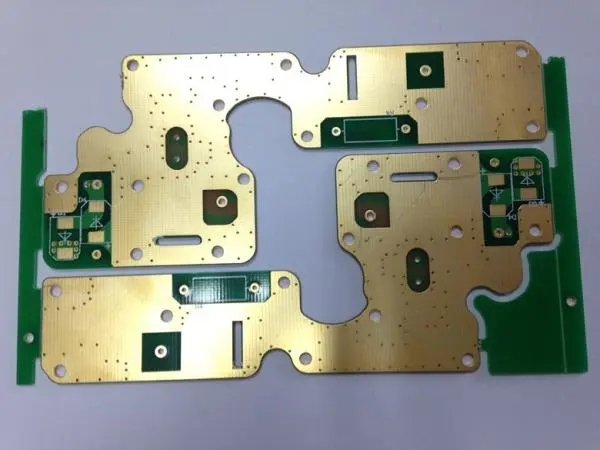

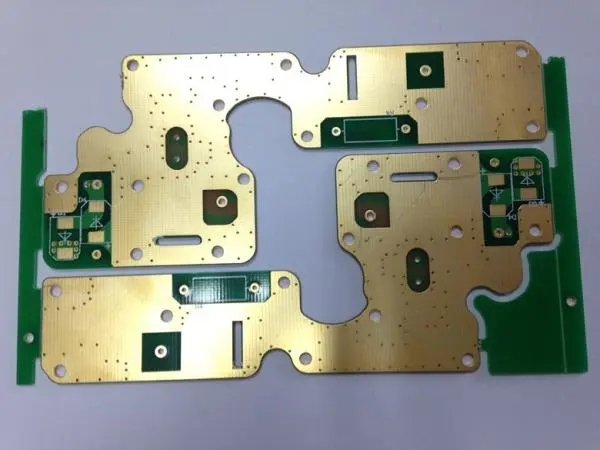

High frequency plate

What is high frequency? The short wave frequency range above 300MHz, that is, the wavelength is more than 1m, is generally called high frequency.

The market of high-frequency microwave board will develop very fast. In the fields of communication, medical, military, automobile, computer, instrument, etc., the demand for high-frequency microwave board is rapidly rising. High frequency microwave boards account for about 15% of the total number of printed boards in the world. Many PCB companies in Taiwan, South Korea, Europe, the United States and Japan have formulated plans to develop in this direction. European and American high-frequency microwave board suppliers have entered the potential big market of China since 2007, looking for agents and teaching related technologies. European and American sheet suppliers have been able to provide more than 100 varieties of sheet series with dielectric constant from 2.10, 2.15, 2.17,... to 10, or even higher.

The demand for high frequency microwave boards is increasing year by year in many domestic PCB factories of radar and communication research institutes. Domestic large communication enterprises such as Huawei, Bell and Wuhan Academy of Posts have increased their demand for high-frequency microwave printed boards year by year. Foreign enterprises engaged in high-frequency microwave products have also moved to China to purchase high-frequency microwave printed boards nearby.

Why the PCB is required to be low ε r(Dk)?

ε R or Dk, called dielectric constant, is the ratio of the capacitance of the electrode charged with a certain substance to the capacitance of the vacuum capacitor with the same structure. It usually indicates the capacity of a material to store electric energy. When ε When r is large, the storage capacity of electric energy is large, and the transmission speed of electric signal in the circuit will be low. The current direction of the electrical signal passing through the printed circuit board is usually positive and negative alternating, which is equivalent to the process of continuously charging and discharging the substrate. In interchange, capacitance will affect transmission speed. This effect is more important in high-speed transmission devices. ε Low r means that the storage capacity is small, and the charging and discharging process is fast, so that the transmission speed is also fast. Therefore, low dielectric constant is required in high frequency transmission.

Another concept is dielectric loss. The energy consumed by dielectric materials due to heating under the action of alternating electric field is called dielectric loss, which is usually based on dielectric loss factor tan δ (delta). ε And tan δ It is proportional, and high frequency circuit also requires ε Low, dielectric loss tan δ Small, so the energy loss is small.

Basic requirements for high frequency microwave board

Due to the high frequency signal transmission, the characteristic impedance of the finished printed board conductor is required to be strict, and the line width of the board is generally required to be ± 0.02mm (the most strict is ± 0.015mm). Therefore, the etching process needs to be strictly controlled, and the film for optical imaging transfer needs to be compensated according to the line width and copper foil thickness. ·The circuit of this kind of printed board transmits not current, but high-frequency electric pulse signal. Defects such as pits, notches and pinholes on the wire will affect transmission, and any such small defects are not allowed. Sometimes, the thickness of resistance welding will also be strictly controlled. If the resistance welding is too thick or too thin for several microns, it will be judged as unqualified. ·Thermal shock 288 ℃, 10 seconds, 1-3 times, no hole wall separation. For polytetrafluoroethylene plate, it is necessary to solve the wettability in the hole, so that there is no hole in the chemical copper sink hole, and the copper layer plated in the hole can withstand thermal shock, which is one of the difficulties in making Teflon porous plate.

Where is the high-frequency microwave board used?

Satellite receiver, base antenna, microwave transmission, car phone, global positioning system, satellite communication, communication equipment adapter, receiver, signal oscillator, home appliance networking, high-speed running computer, oscilloscope, IC test instrument, etc. High frequency microwave printed boards are required in communication and computer fields such as high frequency communication, high-speed transmission, high confidentiality, high transmission quality, and high memory capacity processing. Circuit board manufacturers, circuit board designers and PCBA processors will explain to you the instructions of circuit board manufacturers on high-frequency microwave boards.