How to deal with PCBA processing problems

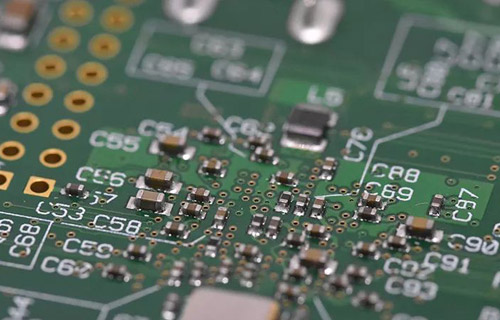

Shenzhen Xingruixiang Electronics provides overall PCBA electronic manufacturing services, including one-stop services from upstream electronic component procurement to PCB production and processing, SMT patch, DIP plug-in, PCBA testing, and finished product assembly. Next, we will introduce how to deal with the problem of PCBA processing tin bead and tin slag. During the processing of PCBA, due to the factors of technology and manual operation, there will inevitably be occasional tin beads and residues on the PCBA board, which will bring great hidden dangers to the use of products. Because tin beads and tin residues will be loose in uncertain environment, PCBA board short circuit will be formed, which will lead to product failure. The key is that this possibility is likely to occur in the product life cycle, bringing sales pressure to customers.

The Basic Cause of Tin Beads and Slags Produced in PCBA Processing

1. There is too much tin on the SMD pad. During reflow soldering, molten tin will extrude corresponding tin beads.

2. When PCB boards or components are exposed to moisture, water will break during reflow soldering, and the spattered tin beads will spread to the board surface;

3. During the post welding operation of DIP plug-in, when tin is manually added and hoisted, the tin beads splashed from the soldering iron head will fall onto the PCBA board;

4. Other unknown reasons.

Measures to Reduce the Slag of PCBA Processing Tin Beads

1. Pay attention to the production of stencil. It is necessary to adjust the hole size according to the specific component layout of PCBA board to control the printing amount of solder paste. Especially when some foot components or panel components are dense.

2. It is recommended to take strict baking action on bare PCB boards with BGA, QFN and dense leg components on the board to ensure that the moisture on the upper surface of the solder board is removed, the solderability is improved to the greatest extent, and the generation of solder beads is eliminated.

3. PCBA processing plant will inevitably introduce manual welder position, which requires strict control of tin swing operation in management. Arrange the special storage box, clean the workbench in time, and the welding and pulling quality control center shall visually inspect the SMD components around the manual welding components, focusing on whether the solder joints of the SMD components are accidentally contacted and dissolved or not. Tin beads and tin residues are scattered between the pins of the assembly. PCBA board is a relatively complex product component, which is very sensitive to conductive objects and ESD static electricity. In the PCBA process, factory managers need to improve their management level (IPC-A-610E Class II is recommended), enhance the quality awareness of operators and quality teams, and implement it from two aspects of process control and ideology, so as to minimize the production of tin beads and tin residues on PCBA boards.

Shenzhen Xingruixiang PCBA processing advantages

Strength guarantee ▪ SMT workshop: It has imported mounters and multiple optical inspection equipment, with a daily output of 4 million points. Each process is equipped with QC personnel who can keep an eye on product quality. ▪ DIP production line: It has two wave soldering machines, including more than ten old employees who have worked for more than three years. The workers are highly skilled and can weld various plug-in materials. 2. Quality assurance, cost-effective ▪ High end equipment can be pasted with precision special-shaped parts, BGA, QFN, 0201 materials. The template can also be pasted and bulk materials can be put by hand. ▪ Samples and large and small batches can be produced, starting from 800 yuan for proofing and 0.008 yuan for batch production, without startup fee. 3. Rich experience in electronic product placement and welding, and stable delivery ▪ Accumulatively serving thousands of electronic enterprises, SMT chip processing services involving various types of automotive equipment and industrial control motherboards, products are often exported to Europe and the United States, and the quality can be recognized by new and old customers. ▪ Delivery shall be on time, and the goods shall be delivered within 3-5 days after the materials are complete. Small batches can also be delivered on the same day in an urgent manner. 4. Strong maintenance ability and perfect after-sales service ▪ The maintenance engineer has rich experience and can repair all kinds of defective products caused by patch welding, which can ensure the connectivity of each circuit board. ▪ 24-hour customer service personnel will respond at any time to solve your order problems as quickly as possible.

How to select PCBA chip processing manufacturers

1、 Customer Experience

Good reputation is a necessary factor for the continuous development of PCBA chip processing manufacturers. When selecting manufacturers, you must check their reputation to see whether they are reliable and trustworthy. There are many ways to investigate, both online and offline. In addition, pay attention to the relevant information of the company and see if there are any negative news. These are important factors to judge whether a PCBA chip processor is reliable. In addition, if you can directly consult the quotation and place an order on the manufacturer's website, its credibility will increase.

2、 Production qualification

The production qualification of PCBA chip processing plants is reflected in many aspects, such as whether they have ISO9001 quality management system certification, whether they have UL certification in the United States, and whether they have European ROHS related production requirements. These are important criteria for judging their qualifications. In addition, through the past cooperation objects and cooperation cases, we can also see whether the production is qualified and high quality.

3、 Cost

Now, the competition in the chip market is also very fierce, and some PCBA chip processing manufacturers will promote low price preferential policies in order to attract customers. These preferential policies seem to be much cheaper on the surface, but they may be the price of quality. For enterprises, the gain is not worth the loss. You should know that high-quality products bring not only good use of products, but also customer reputation. Not only that, the decrease in cost means that investment will inevitably be reduced in some aspects, which may reduce its quality and affect its future development. Therefore, when PCBA chip manufacturers want to attract you with low prices, they must be careful.

4、 Services

Powerful PCBA ship processing manufacturers will provide customers with perfect services, including pre-sales, sales and after-sales, and each link can make customers feel the most intimate service. Therefore, when judging whether the PCBA chip processing factory is reliable, we can start from the service. For example, before sales, whether reliable manufacturers have the ability to make appropriate solutions for customer needs, during sales, whether they can quickly solve problems encountered by customers, and whether they can provide timely and professional services after sales. When the customer has questions, can the manufacturer carefully answer and solve the customer's doubts and difficulties, strengthen the customer's trust, respond in a timely manner, and provide strong technical support to the customer. The above four perspectives are the important basis for selecting PCBA chip processing manufacturers. In addition, product quality, technical support, value creation, etc. can be the criteria for judging whether PCB chip processing manufacturers are worthy of cooperation. Here, we also remind enterprises to be careful in their choices.