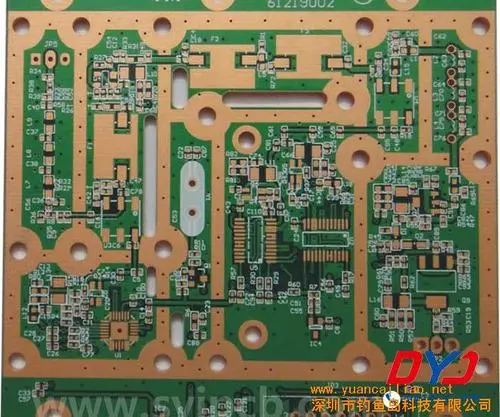

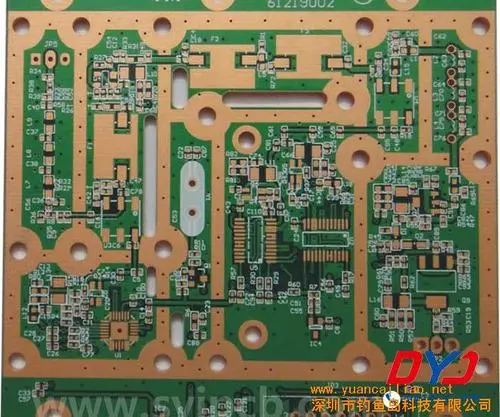

The manufacturing process of PCB liquid photosensitive solder mask and dry film solder mask is as follows:

1. Curtain Coating

It is an automatic application method of light-sensitive green paint coating on circuit board surface. The paint is a thinned, non water-soluble green paint ink. During the construction, this green paint will flow down from a long strip opening in a continuous flow of water, and vertically intersect with the board in the process of automatic transportation. A layer of uniform paint film is applied on the board surface. After the solvent escapes and semi hardens, the board body is turned over and the other side is coated. When both sides are completed, You can transfer the image of the photosensitive method. This "Lian coating method" is not a new creation of the circuit board industry. In the early years, it was also used for automatic painting of wooden furniture, but now it is used in other fields.

2. Encroachment

In the PCB industry, when green paint is specially applied to the board, when green paint traces are accidentally found on the surface of the welding pad that should not be painted (i.e. the hole ring hole wall of the jack or the SMT board surface welding pad, etc.), it will seriously affect the solderability of the downstream assembly, which is specifically called Encroachment.

3. Liquid Photosensitive Solder Mask, LPSM

It is a kind of anti soldering green paint used for the board surface. Due to the growing number of fine wire boards, the early screen printing baking type epoxy resin green paint has been unable to adapt to it. Instead, the "empty" (or screen with only ink blocking spots) full screen printing is used for the construction of light sensitive green paint. After scraping and semi hardening, the film can be directly used for accurate alignment and exposure, and then the green paint with accurate position can be obtained after imaging and hardening. The LPSM in service has been tested by mass production for several years, and its quality has been very good. Now it has become the mainstream of all kinds of anti welding films.

4. Post Cure subsequent hardening and baking

In the PCB circuit board industry, the liquid photosensitive green paint or solder proof dry film needs to be further hardened after the completion of the development to enhance the solder resistance of its physical properties. This supplementary work is called "subsequent hardening". In addition, when the polyimide multilayer board is pressed, in order to have a more complete polymerization reaction, it must be put back into the oven to continue to bake for 2 to 4 hours, also known as Postcure.

5. Roller Coating

Green paint or "photosensitive line ink" is coated on the board surface with rollers, and then semi hardening exposure and imaging are carried out. This method is very beneficial for boards with low price and large output.

6. Solder Mask (S/M) green paint, solder mask

Although Solder Mask is commonly used in terms of the original text, it is still more formal to use Solder Resist. The so-called solder mask refers to the permanent resin film covering the conductors that do not need to be welded on the PCB surface, which is called S/M. The green paint can not only prevent welding, but also protect and insulate the covered lines.

7. Spray coating

The compressed air is used to spray the liquid paint from the small mouth, and the tiny atomized particles are sprayed on the surface of the object to be treated. Similar to "painting", it is called "spraying". The electrostatic device can also be applied at the nozzle to make the sprayed fog point have static electricity, and the opposite static electricity can also be applied to the processing piece itself to make direct adsorption. It can not only save paint and reduce pollution, but also make dead corners evenly distributed, which is called "electrostatic spraying method". The new green paint processing of circuit boards has also adopted this method.

8. Tackiness

After the liquid photosensitive green paint (LPSM) is coated on the PCB surface (such as empty screen printing, vertical flow, spraying, vertical scraping, roller coating, etc.), it should also be pre baked for exposure. The property of whether the pre baked paint surface will stick to the negative under strong light is called Tackiness. After the solder paste and parts are printed on the downstream SMD welding pads, the solder paste must temporarily present the function of sticking and positioning, also known as Tackness, before waiting for infrared and hot air fusion welding.