The main reasons and preventive measures for PCB drillbit breakage are as follows:

1. PCB drilling parameters: the setting of drilling parameters is very important. Too fast drilling speed will cause the drill bit to break due to excessive stress. Too slow drilling speed will reduce production efficiency. As the thickness, copper thickness and sheet structure of PCB boards produced by PCB manufacturers are different, PCB needs to be set according to specific conditions. Select the most appropriate drilling parameters through calculation and testing. Generally, for a 0.3mm drill bit, the cutting speed should be 1.5-1.7m/min, and the drilling depth should be controlled between 0.5-0.8.

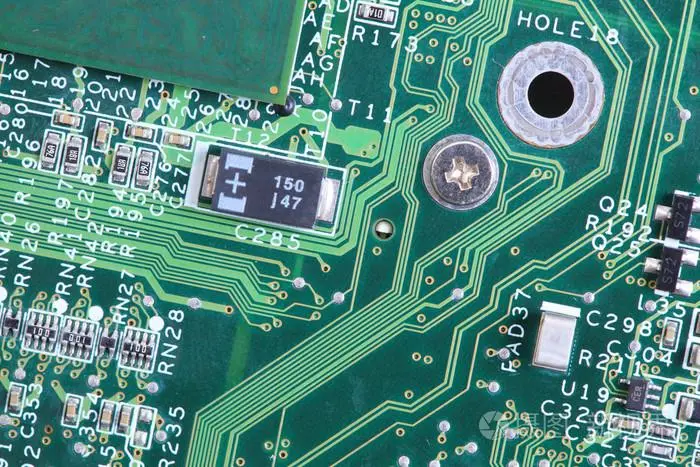

2. The base plate used for the base plate and aluminum sheet drilling shall be of moderate hardness, uniform thickness, flatness, and the thickness difference shall not exceed 0.076 mm. If the base plate is irregularly distributed, the drill nozzle is easy to be stuck. The uneven base plate will cause the pressure foot to be not tight, which is the twist and fracture of the drill nozzle. The plate will also move with the drill nozzle when it moves up and down. The drill nozzle will break due to unbalanced force when it returns the tool. Its role is:

(1) Suppress the occurrence of burr in the hole.

(2) Fully penetrate the PCB board.

(3) Lower the temperature of the drill bit edge to reduce drill break.

The aluminum sheet used for drilling shall be rigid to prevent the plate from vibrating when lifting the knife, and shall have corresponding elasticity. The drill bit becomes soft at the moment of contact when running in, which means that the drill bit is accurately aligned with the position of the hole to be drilled and will not deviate from the original hole position, resulting in the drill bit breaking.

Function of aluminum sheet:

1. Prevent burrs and scratches on the surface of PCB board.

2. It plays the role of heat dissipation and bit cleaning.

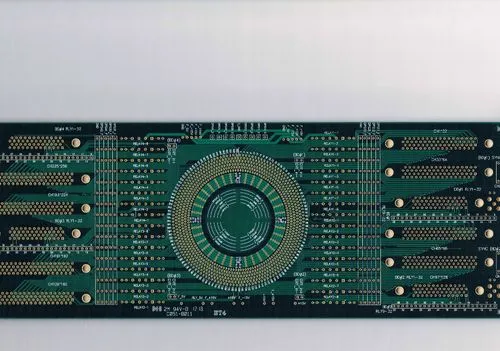

3. It can guide the drill bit to drill into the track of PCB board to improve the accuracy of drilling.

The aluminum sheet shall have a large thermal conductivity, which can quickly take away the heat generated during drilling and reduce the temperature of the drill bit. 0.15-0.2mm thick aluminum sheet or 0.15-0.35mm aluminum alloy composite aluminum sheet shall be used as far as possible to effectively prevent the drill bit from breaking due to poor chip discharge caused by high temperature during drilling.

3. The quality of PCB copper clad sheet The glass fiber cloth of the sheet is thick and the binding force is poor, which will also have a greater impact on the broken drill bit. If the resin polymerization of the plate is not complete, it is easy to cause too much glue residue on the hole wall, poor chip removal and broken drill bit. If there is a cavity in the base plate, the drill bit will be broken due to uneven stress during drilling. Therefore, the sheet must be baked before drilling. Baking time is generally 4 hours/150oC ± 5oC

4. When using drill bits, drill bits with different functions must be selected according to the processing purpose, product hole wall quality requirements and purpose. The main categories of drill bits are 1: ST type (straight drill) 2: UC type (under cut drill) 3: ID type (inverse drill). At present, the most commonly used type is ST type, which is applicable to double-sided boards containing paper, epoxy paper, phenol epoxy glass and other sheets and PCB boards with less than four layers. UC drill bit is characterized by that the diameter below the tip head is smaller than that above the head (that is, the head is larger than the body). The design principle is to reduce friction with the hole wall during drilling to prevent the hole wall from being too thick and the needle from breaking. It is very important to choose a supplier with timely supply, stable quality and perfect after-sales service.

5. The machine performance must ensure that the drilling machine is in a stable and accurate state during PCB drilling production. Because the vibration of the drilling machine, the vibration of the spindle and the RUNOUT are too large, the COLLET design is poor or there are sundries, the Z axis is not free and the dust removal is not good, and the (X, Y) axis is not moving well, the drill bit is broken. Therefore, the drill with good performance should be selected according to the PCB board factory's own customer group and product structure. Under normal conditions, the height difference between the highest and lowest levelness of the machine table is required to be<0.125mm, and the movement accuracy deviation of X and Y axes is required to be<0.076mm.

SPINDLE dynamic RUNOUT<2. 5um. Compressed gas temperature=room temperature. Dew point=3oC, oil residue ≤ 0.01mg/m3, solid residue ≤ 0.1um (otherwise, there will be water and oil in SPINDLE, which will affect the service life and drilling accuracy of SPINDLE), and the dust suction force is 100-150Mbar. The pressure of the pressure foot shall be 21-24N/CM2. The presser foot of each drill shaft shall be adjusted to be about 1.3mm longer than the drill bit. When drilling, the presser foot pad will press the aluminum sheet before drilling in. When withdrawing the tool, the drill bit will be lifted before the presser foot pad leaves the board, otherwise the drill bit will be easily broken. The accuracy of CNC drilling shall be inspected and adjusted regularly.

6. PCB working environment has high requirements for 5S in PCB production workshop to reduce dust. The marble table and beam of the machine should be wiped with alcohol for daily maintenance. Keep clean. The temperature of the operation room is controlled between 20oC ± 2oC to ensure that the machine can work in an adaptive environment, ensure the PCB quality and ensure the life of the NC drilling rig.