flexible PCBs, flex circuit or flex PCB, is an alternative to traditional wiring harnesses and is a flexible PCBs board compared to rigid PCB.

flexible PCBs can be manufactured as single-sided, double-sided or multi-layer plating from printed circuit boards. This allows complete wiring of compact devices and systems, with the advantage that no additional cables or plug connectors are required.

Flex design presents unique challenges to most PCB tools, as traditional object inspection does not account for the nuances of flex inspection. They present a new set of objects that are best considered during the design phase.

This forces designers to incorporate changes into build manufacturing after design data is closed. The manufacturer must then perform a Flex-based inspection of the design and forward the problem to the designer. This leads to a frustrating cycle of delayed product launches and wasted money.

Working with manufacturers up front to incorporate their knowledge base into intelligent inspection machines can reduce or eliminate this iterative information. As more data is shared, the rules can be adjusted, enabling even the most inexperienced Flex designers to produce effective designs.

Due to the flexibility of the layers, static or permanent dynamic bending is possible, providing additional functionality depending on the specific application. In addition to the usual electronic component connections, flexible PCBss can also take over mechanical tasks, such as accessing components on a device housing.

With this connection technology, tight installation spaces can be used perfectly, as these flexible PCBss allow three-dimensional mounting.

machining contour

1. Milling

2. Punching

3.Lasering

ZIF connector

1.Zero Insertion Force Connector

2.Electroplated ZIF connector

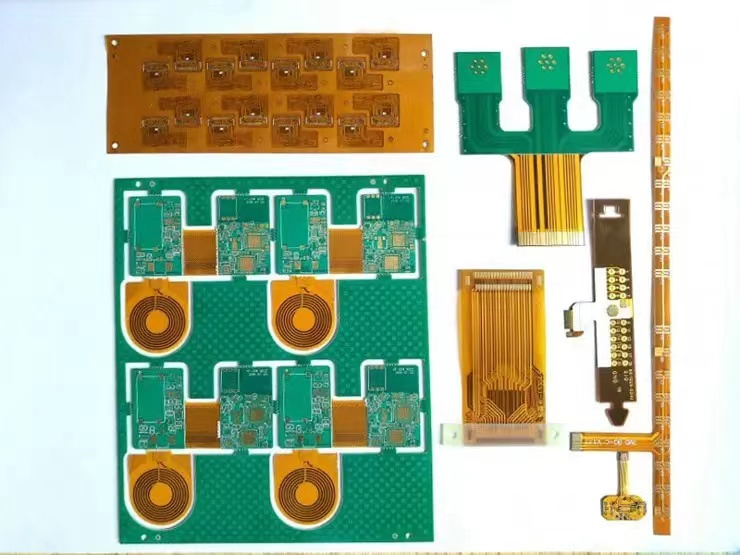

Polyflex and finger flex circuits

Directly pluggable fingers up to 250μ

flexible PCBs with Assembly Frame

easy to assemble

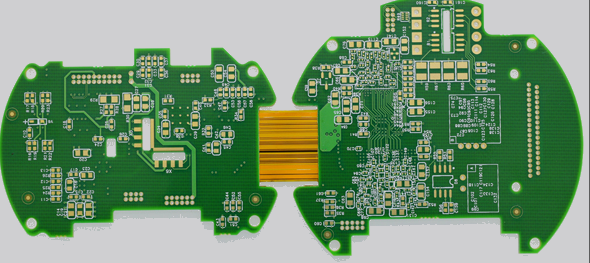

Kingsunpcb provides a way to integrate multiple PCB assemblies, eliminating wires, cables or connectors, replacing them with flexible substrates between rigid sections.

Flexible circuits allow the circuit board to conform to the desired shape (bend) during its application.

Our products can be found in a range of ultra-high reliability markets, including aerospace, space and defense. We have accumulated extensive manufacturing experience, product knowledge and technical expertise by working closely with many leading OEMs.

Single-sided Flexible material, with or without stiffeners (one conductive layer).

Double-sided flexible material, with or without stiffeners (two conductor layers), with plated-through holes.

Multilayer flexible material tape or stiffener (more than two conductor layers) with plated through holes and HDI.

Multilayer rigid and flexible material combination (more than two conductor layers) with plated through holes and HDI.c

The above is an introduction to the differences in performance, requirements and manufacturing processes between flexible PCB and rigid PCB. I hope it will be helpful to you.