PCB demand analysis of new energy vehicles

Automotive Industry Mechanics and Electronics Combined

Due to the complex working environment of automobiles, automotive PCB has extremely high requirements for reliability. Secondly, the automotive industry has a recall system. Manufacturers need to bear the risk of product errors. Small-scale manufacturers cannot afford it, so they will be excluded. Moreover, the entry threshold for automotive PCB is high, and a series of verification tests must be passed. The certification cycle is long. Once the certification is passed, manufacturers generally will not easily change suppliers, and orders are relatively stable.

Automotive electronics can be mainly divided into two categories: car body electronic control system and vehicle electronic control system. The car body control system can be divided into engine control system, body control system and chassis control system. The car body control system enables the combination of automotive mechanical systems and electronic devices, giving full play to the advantages of electronic products and improving the performance of mechanical systems. The driving of the car is safer and more stable.

The vehicle electronic control system mainly includes multimedia system, navigation system, driving recorder, reversing radar and other systems, which increases the convenience and entertainment of the car and improves the car experience.

Intelligent driving has opened up a greater imagination space for the automotive economy, and its penetration rate in the automotive market is currently increasing. The ADAS system (advanced driver assistance system) market is growing rapidly, gradually penetrating into the mid-end market from the original high-end market, and the improved new sensor technology is also creating new opportunities for system deployment. At present, the penetration rate of ADAS is less than 5%. With the further expansion and improvement of functions, as well as policy encouragement and even mandatory requirements, it is expected to grow at a rate of more than 20% in the future. By 2020, the market size is expected to be close to 30 billion US dollars. A variety of operation control, safety control, and peripheral control functions in ADAS require PCBs to be implemented. It is expected that cars that will achieve fully autonomous driving in the future will be equipped with more PCBs to meet driving needs.

China's Intelligent Driving Market Size and Forecast

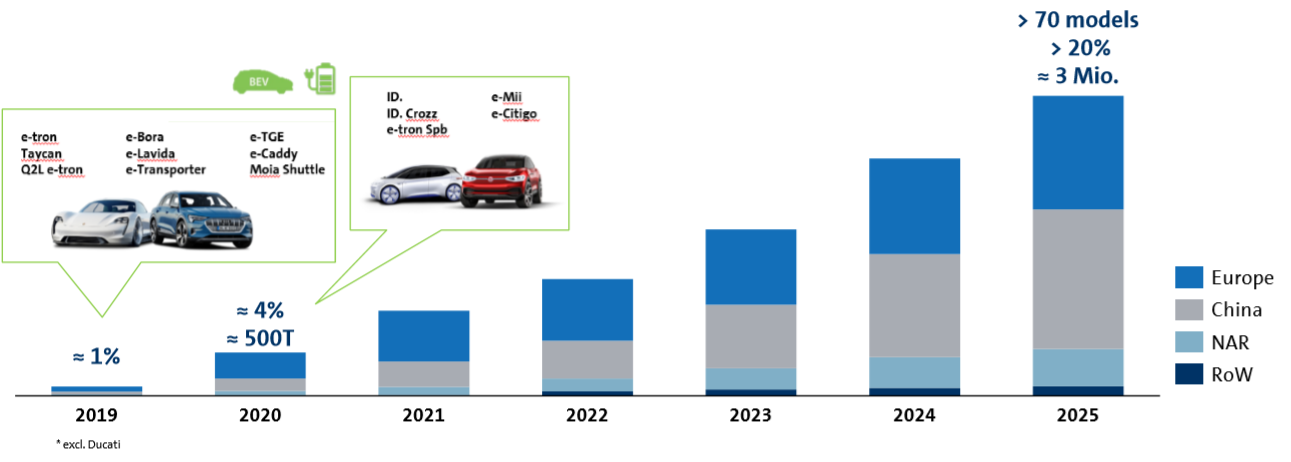

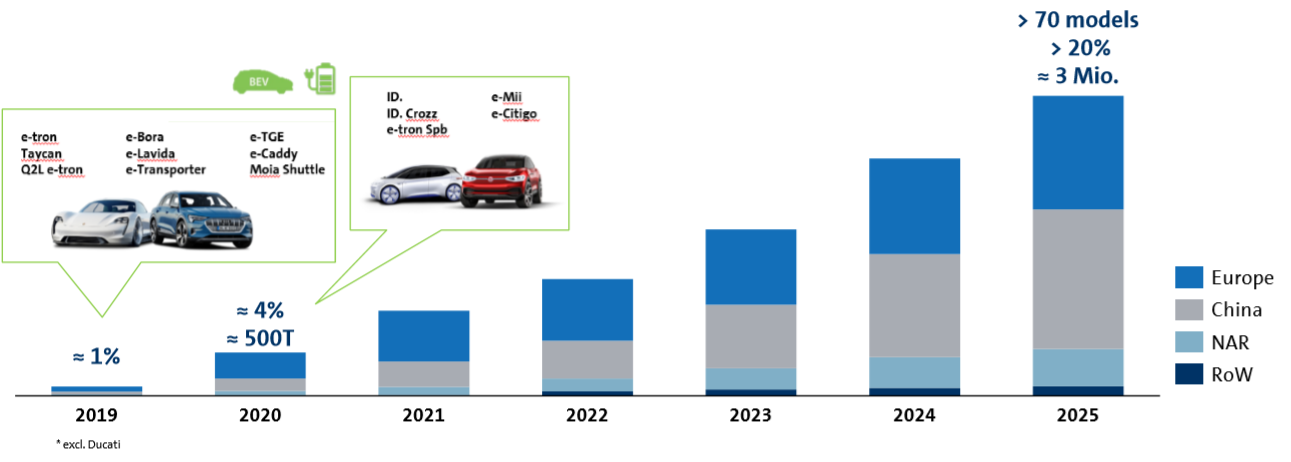

The demand for PCBs in new energy vehicles also has great potential. With the support of industrial policies, the domestic new energy vehicle market has maintained rapid growth since 2014. BMS in new energy vehicles is one of the core components, and as one of the basic components of BMS, PCB boards will also benefit from the development of new energy vehicles.

Compared with traditional vehicles, new energy vehicles have a higher degree of electronics. New energy vehicles are represented by electric vehicles. Compared with traditional fuel vehicles, the main difference lies in the four major components, drive motor, speed controller, power battery, and on-board charger. The on-board battery is mainly used as the energy source and the motor is used as the power. The source drives the vehicle. Compared with traditional cars, new energy vehicles have higher requirements on the degree of electronics. Electronic devices account for about 25% of the cost of traditional high-end cars, and 45%-65% of the cost of new energy vehicles.

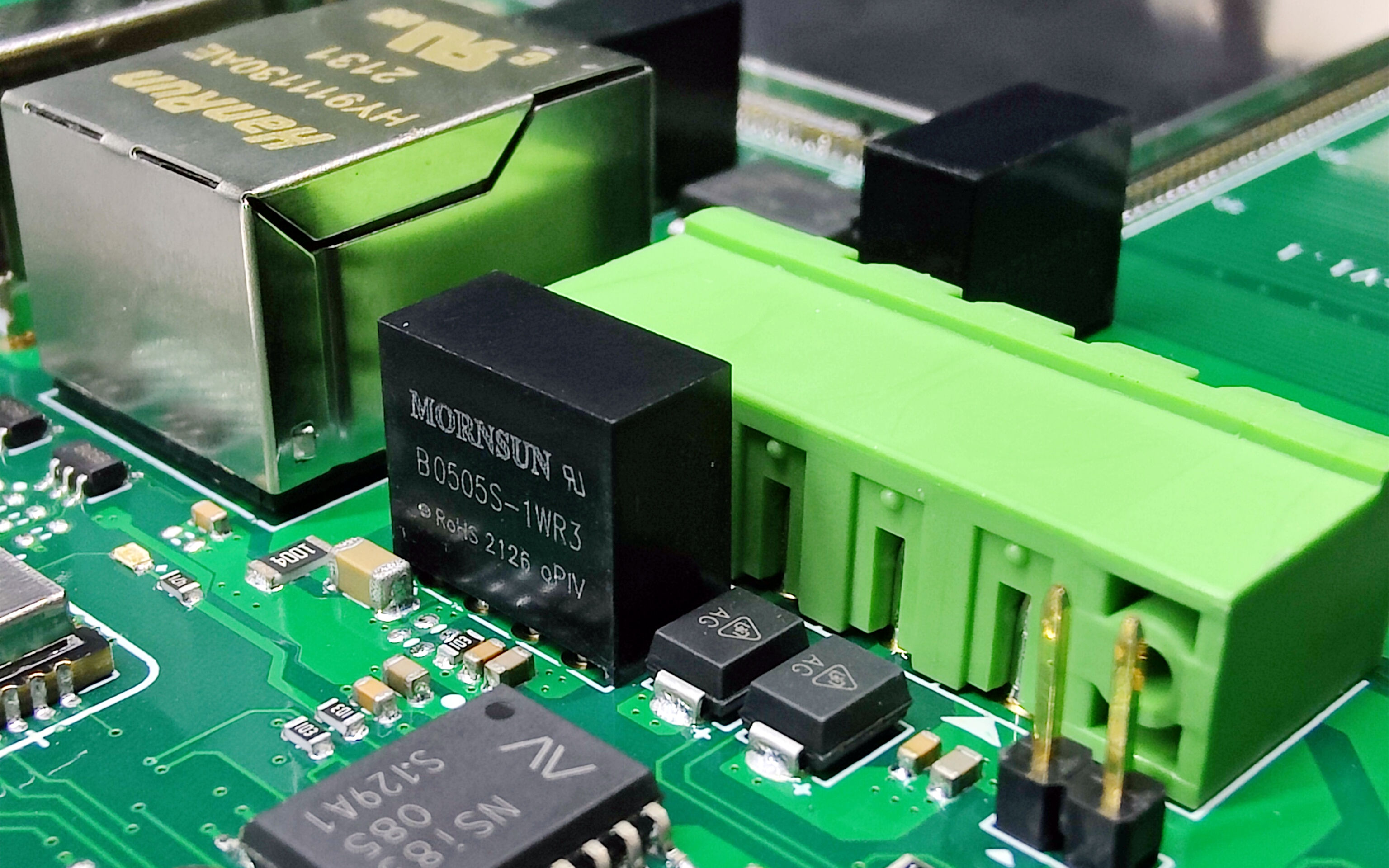

New energy vehicle BMS: a new growth point for automotive PCB. Lithium battery is the core energy of new energy vehicles. In order to ensure the safe and reliable operation of the battery, it is necessary to monitor the battery in real time through the battery management system (BMS). BMS is also called the brain of the battery system of the electric vehicle. The system together constitutes the three core technologies of electric vehicles. PCB is the hardware foundation of BMS. A large bus has 12-24 boards, and a small car has 8-12 boards. The main control circuit consumes about 0.24 square meters, and the single management unit is 2-3 square meters. Automotive PCB will usher in a large volume with the growth of the market size of new energy vehicles.

ADAS (Advanced Driver Assistance System: Advanced Driver Assistance System) is a transition before the realization of fully autonomous vehicles. It uses various sensors installed on the vehicle to collect environmental data inside and outside the vehicle in the first place. Carry out technical processing such as identification, detection and tracking of static and dynamic objects, so that the driver can detect possible dangers in the fastest time, so as to attract attention and improve safety. Active safety technology, ADAS technology principle and The human reaction mechanism is similar. The surrounding information is obtained through the perception layer, the information is processed by the decision-making link, and finally the calculation result is sent to the execution device to complete the driving operation.

Principles of ADAS technology

Millimeter-wave radar is the core sensor of the ADAS system. Millimeter-wave radar refers to the radar that works in the millimeter-wave band. It uses radar to transmit radio to the surroundings, and calculates the distance, direction and size of obstacles by measuring and analyzing reflected waves. Millimeter wave radar can be divided into 24GHz radar and 77GHz radar. The 77GHz millimeter-wave radar can measure the speed of the vehicle in front and the distance between the two vehicles, and at the same time monitor the speed and distance of the own vehicle. The 24GHz millimeter-wave radar is mainly used to monitor objects near the vehicle.

Working principle of automotive millimeter wave radar

The heavy volume of millimeter-wave radar will bring huge demand for automotive high-frequency PCBs. At present, automotive millimeter-wave radars are developing at a high speed. In the next two years, automotive millimeter-wave radars will be in a period of heavy volume. Generally, cars that support ADAS functions will use at least 4 millimeter-wave radars. The new Audi A4 uses 5 millimeter-wave radars, and the Mercedes-Benz S It is expected that the average number of millimeter-wave radars used in a single vehicle will continue to grow in the future, and the demand for automotive radar PCBwill also grow rapidly.

Millimeter-wave radar products are about to enter the heavy-duty period, and high-frequency PCBAboards are required to realize the function of the antenna—to maintain sufficient signal strength of the antenna in a small integration space. High-frequency PCBA boards with higher specifications for 77Ghz radar will bring huge demand for corresponding high-frequency PCB boards when they are widely used.