1. Mosaic

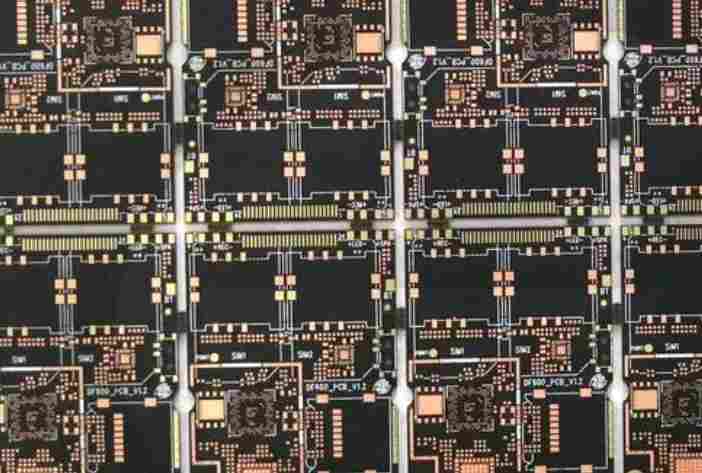

PCB design is completed because the PCB board shape is too small to meet the requirements of the production process, or a product is composed of several PCB, so it is necessary to assemble several small boards into a large board that meets the production requirements, or to assemble multiple PCB used in a product to facilitate the production and installation. The former is similar to the stamp board, it can meet the PCB production process conditions and easy to install components, use and then separate, very convenient; The latter is a product of several sets of PCB board assembled together, so easy to produce, but also easy to a product set, clear.

2. Data generation

PCB board production is based on the film base. In the early production of a film base, it was necessary to make a film base map first, and then use the base map for photography or reproduction. The accuracy of the base map must be consistent with that required for the printed board, and consideration should be given to compensating for deviations caused by the production process. The base map may be provided by the customer or produced by the manufacturer, but both parties shall cooperate and negotiate closely to make it meet the requirements of the user and adapt to the production conditions. Where the user provides the base drawing, the manufacturer shall inspect and approve the base drawing, and the user may evaluate and approve the original or first printed board product. Base map production methods include manual drawing, mapping and CAD drawing. With the development of computer technology, printed board CAD technology has made great progress, and the level of printed board production technology has been continuously improving to the direction of multi-layer, fine wire, small aperture and high density. The original film plate-making process has been unable to meet the design needs of printed board, so the emergence of light painting technology. The PCB circuit board graphic data file designed by CAD can be directly sent to the computer system of the optical drawing machine, and the optical drawing machine can be controlled to draw graphics directly on the negative with light. Then through development, fixing to get the film base version. The use of light painting technology to produce the printed board film base plate, speed, high precision, good quality, and avoid the human error in the manual mapping or drawing the base map may appear, greatly improve the work efficiency, shorten the production cycle of the printed board. Laser light painting machine, in a very short time to complete the past many people for a long time to complete the work, and its drawing of fine wire, high-density base is also incomparable to manual operation. According to the different structure of laser light painting machine, it can be divided into flat plate type, Internal Drum and External Drum. The standard data format used by the optical drawing machine is Gerber-RS274 format, which is also the standard data format for the printed board design and production industry. The Gerber format is named after the American Gerber company, a pioneer in the design and production of light drawing machines. The production of optical drawing data is to convert the design data generated by CAD software into optical drawing data (mostly Gerber data), which is modified and edited by CAM system to complete the optical drawing pre-processing (plate, image, etc.), so that it can meet the requirements of the printed board production process. Then the processed data is sent to the optical drawing machine, which is converted into Raster data by the raster image data processor of the optical drawing machine. The raster data is sent to the laser optical drawing machine through the high speed compression and restoration algorithm to complete the optical drawing.

3. Optical drawing data format

The optical drawing data format is developed on the basis of Gerber data format of vector optical drawing machine, and the data format of vector optical drawing machine is extended, and compatible with HPGL HP plotter format, Autocad DXF, TIFF and other special and general graphics data formats. Some CAD and CAM developers also extend the Gerber data.

The following is a brief introduction to the Gerber data. Gerber data is officially known as Gerber RS-274 format. For each symbol on the CODE disk of vector optical drawing machine, there is a corresponding D code (D-code) in Gerber data. In this way, the optical drawing machine can control and select the code disk through D code, and draw the corresponding graphics. The shape and size of D code and the corresponding symbol of D code are listed, that is, a D code table is obtained. This D code table becomes a bridge from CAD design to light drawing machine using this data for light drawing. When providing Gerber light drawing data, users must provide the corresponding D code table. In this way, the light drawing machine can determine what type of symbol disk should be selected for exposure according to the D code table, so as to draw the correct graphics. In a D code table, it should generally include D codes, each D code corresponding to the shape of the disk, the size, and the exposure mode of the disk.