Wearable device has great potential in chip manufacturing due to lack of core

Circuit board manufacturing, circuit board design and PCBA processing manufacturers explain the great potential of chip manufacturing in wearable devices

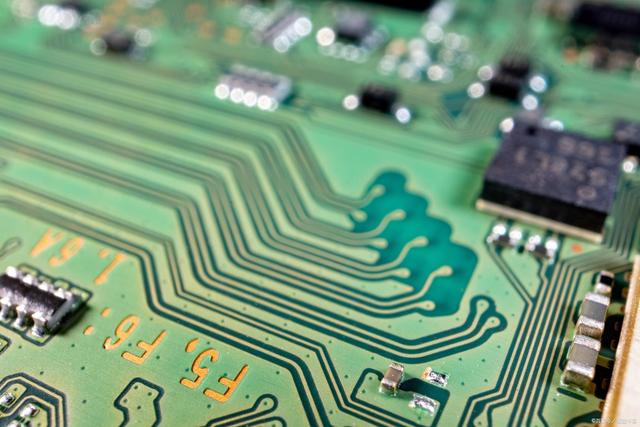

The chip is like the human brain. Especially for wearable devices, chips not only determine the operation of devices, but also determine the role of the industry in the international division of labor. Although the wearable device industry is flourishing in China at present, and the manufacturing of the entire terminal products accounts for more than 80% of the global share, as far as the chips in the upstream of the industrial chain are concerned, we are a little unable, especially in the face of high-end chips. IC decryption takes the most popular smart watch and smart bracelet products as an example, and chips are also facing a difficult situation.

At present, the main control chip is mainly composed of AP and MCU. The bracelet uses MCU, while the watch uses MCU or AP according to the function complexity; There is no master control chip specially customized for wearable devices, but only optimized design based on the original platform. With the focus on the Internet of Things, wearable devices will be known by more people, and the entire industry will also receive greater attention. Then, the chip problem following IC decryption will become the central problem that enterprises in the entire industry have to face.

The "lack of core" of the industry is a little painful

Wearable devices are the most popular smart terminal hardware based on mobile Internet after smart phones. Whether it is Google, Apple, Microsoft, Intel, or Samsung, Sony and other international giants plan the wearable device category. Of course, domestic manufacturers are more hot. In addition to the "thriving" wearables in Huaqiangbei market, some medical device enterprises and traditional entity enterprises have entered this category. Various forms of wearable devices emerge in endlessly, and the popularity of the IC decryption industry does not seem to be in direct proportion to the market performance, presenting a situation of polarization, and the roast voice inside and outside the industry is always greater than the praise voice.

Of course, the appearance of this situation is a normal phenomenon of industrial development. On the one hand, it is the rise of emerging industries, which is a time process from users' cognition to demand bearing; On the other hand, of course, the industrial products themselves need a constantly improved process of IC decryption, and each link of the industrial chain in this process needs a certain time to improve and optimize.

At present, from the perspective of wearable devices, with the constant miniaturization of products, they put forward higher requirements for the design of low power consumption. However, the ideal situation is that the entire industrial chain from chip design, product planning, algorithms to application services is not yet perfect, and the entire industrial chain is still in the stage of evolution.

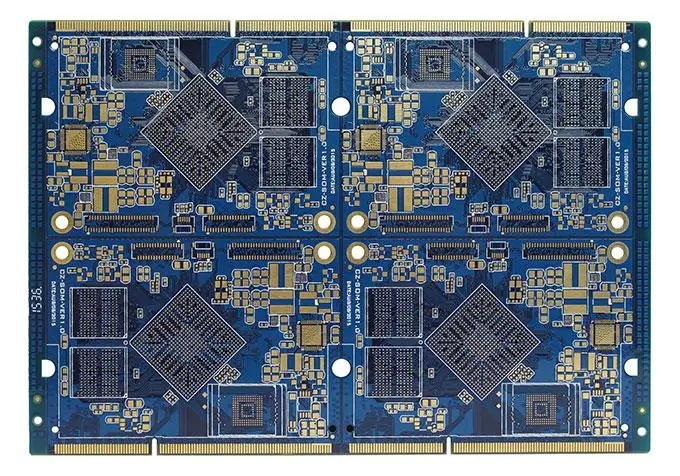

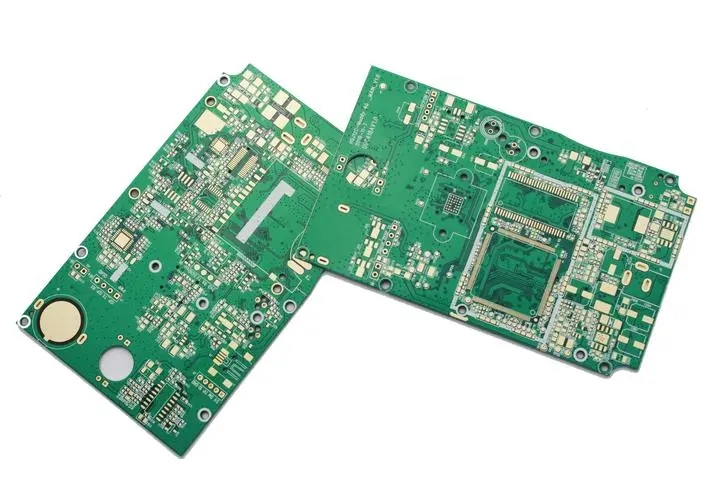

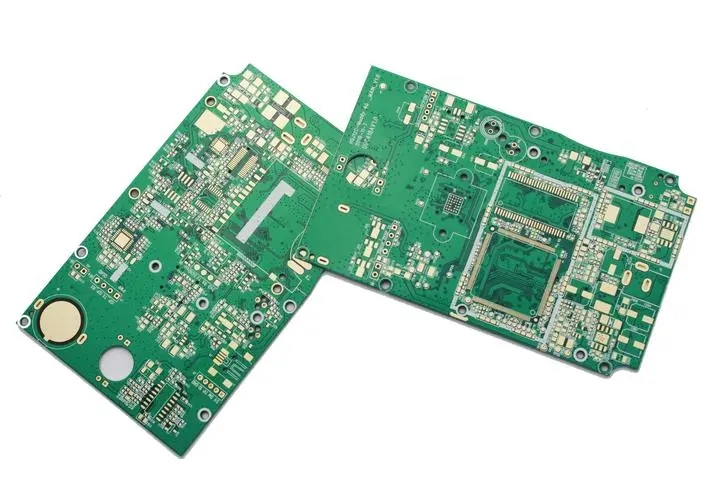

Conventional wearable devices are usually composed of such key components as screen, chip, wireless communication IC decryption and sensor. In order to obtain "benefits" in this wave, most start-ups usually choose the supply chain integration and assembly method. The common way is to find a plan designer to provide a product technology plan, and then purchase chips, sensors, display screens, wireless communication and other modules, and then find a design company to stop the design and development of the appearance, and then customize the design of an APP, rent a third-party server, and put together a product. A more simple rule is to directly find an existing OEM manufacturer. After IC decryption, a wearable device will come out with my own trademark. The result of this integrated product development mode is what we all think today: product homogeneity, and lack of "pain point" technology.

Circuit board manufacturers, circuit board designers and PCBA manufacturers explain the great potential of chip manufacturing for wearable devices with core missing and pain points.