The reason why PCB can be used more and more widely is that it has many unique advantages, which are summarized as follows.

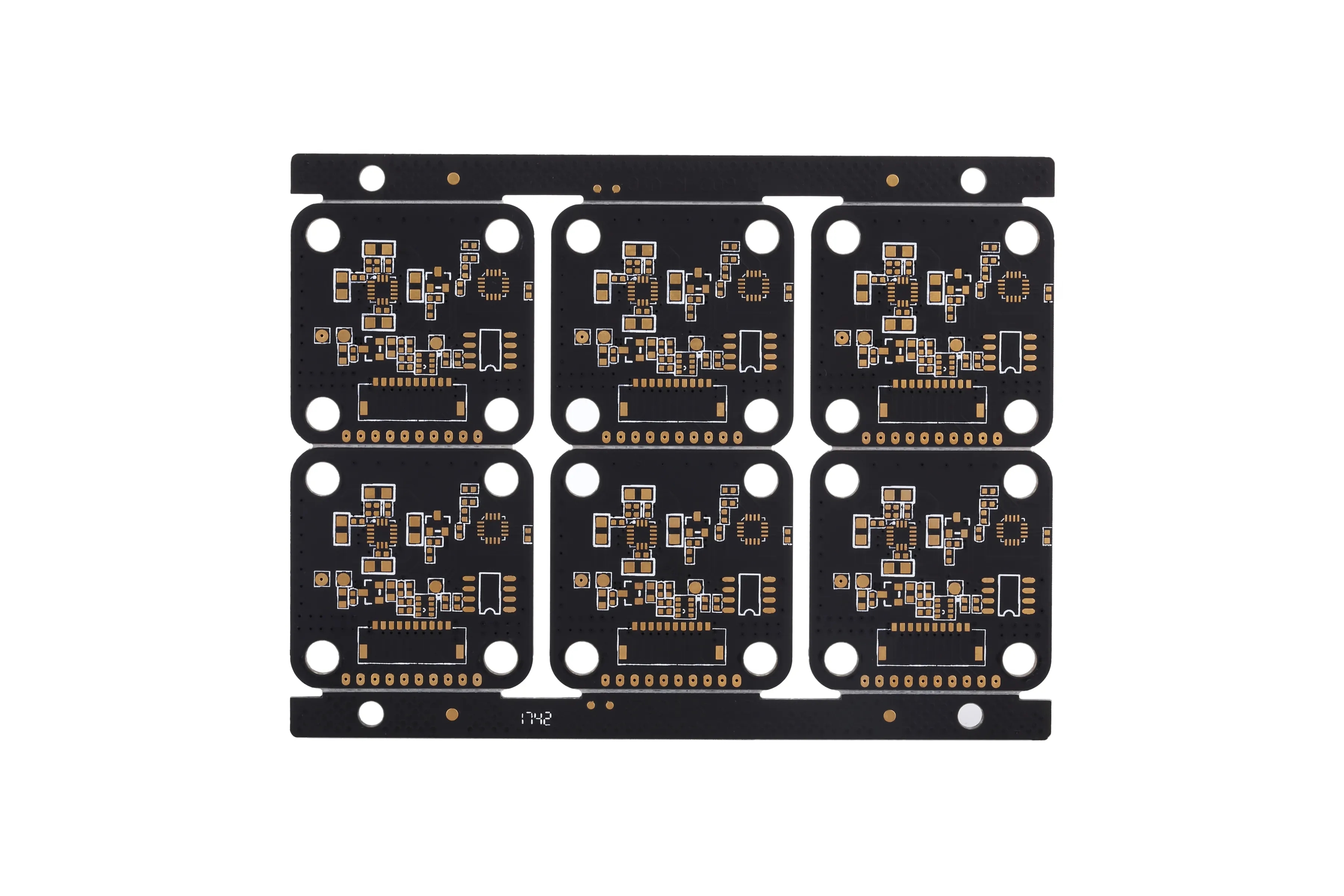

PCB

It can be high-density. For decades, the high density of printed boards has been developing with the improvement of integrated circuit integration and installation technology.

High reliability. Through a series of inspections, tests and aging tests, the PCB can be guaranteed to work reliably for a long time (service life, generally 20 years).

Possibility. For various performance requirements of PCB (electrical, physical, chemical, mechanical, etc.), PCB design can be realized through design standardization, normalization, etc., with short time and high efficiency.

Possibility. With modern management, standardization, scale (quantity), automation and other production can be carried out to ensure product quality consistency.

Testability. A relatively complete test method, test standard, various test equipment and instruments have been established to test and identify the qualification and service life of PCB products.

Assemblability. PCB products are not only convenient for standardized assembly of various components, but also can be used for automatic and large-scale batch production. At the same time, PCB and various PCB component assembly parts can also be assembled to form larger parts and systems, up to the whole machine.

Maintainability. Because PCB products and various component assembly parts are designed and produced in a standardized way, these parts are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the system can be recovered quickly. Of course, we can give more examples. Such as miniaturization, lightweight, high-speed signal transmission, etc.

Application Differences between PCB Prepreg and Core

The differences between PCB Prepreg and PCB Core are as follows:

Prepreg is a thin piece of insulating material. Prepreg is not prepreg before being laminated, which is also called prepreg material. It is mainly used as the bonding material and insulating material for the inner conductive patterns of multilayer printed boards. After the prepreg is laminated, the semi cured epoxy resin is extruded, starts to flow and solidify, and the multilayer is bonded together to form a layer of reliable insulator.

Core is the basic material for making printed boards. Core, also known as PCB core board, has a certain hardness and thickness, and is copper clad on both sides. Therefore, the multilayer board is actually a composite of Core and Prepreg.

Differences between the two:

1. Prepreg is a kind of material in PCB. The former is semi-solid, similar to cardboard, while the latter is hard, similar to copper;

2. Prepreg is similar to adhesive+insulator; Core is the basic material of PCB, and the two functions are completely different;

3. Prepreg can curl while Core cannot bend;

4. Prepreg is non-conductive, and the core has copper layers on both sides, which is the conductive medium of PCB.

From the perspective of our PCB industry, the prepreg prepreg is equivalent to glue, which is used to connect several cores by lamination.