Circuit board processing manufacturer explains the production of blind hole board

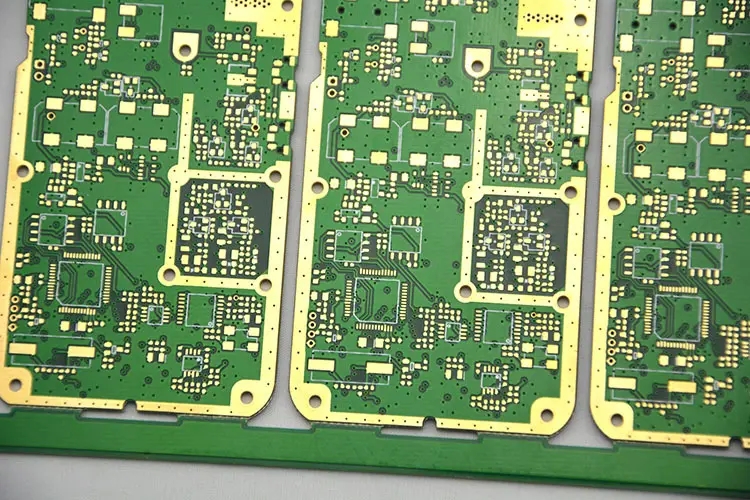

Circuit board manufacturing, circuit board design and PCBA processing manufacturers will explain to you the manufacturing of blind hole boards

With the development of electronic products to high density and high precision, the same requirements are put forward for circuit boards. The most effective way to improve the density of PCB is to reduce the number of through-hole, and precisely set the blind hole board (PCB/PCB) and embed the hole.

1、 Definition of blind hole circuit board

a: In contrast to through holes, through holes refer to holes drilled through each layer, while blind holes refer to non drilled through holes. (As shown in the figure, for example, the eight layer plate: through hole, blind hole, and buried hole) b: blind hole subdivision: blind hole, buried hole (the outer layer is invisible); c: Distinguish from the manufacturing process: blind holes are drilled before pressing, while through holes are drilled after pressing.

2、 Fabrication method

1. Drilling belt:

A: Select reference point: select a through hole (i.e. a hole in the first drill strip) as the unit reference hole.

B: Each blind hole drilling belt needs to select a hole and mark its coordinates relative to the unit reference hole.

C: Note which drill belt corresponds to which layers: unit hole division diagram and drill bit table shall be indicated, and the names shall be consistent; It is not allowed that the hole division diagram is represented by a b c and the previous one is represented by 1st and 2nd.

Note that when the laser hole is sleeved with the embedded hole in the inner layer, that is, the holes of the two drill tapes are at the same position, the customer needs to move the position of the laser hole to ensure electrical connection.

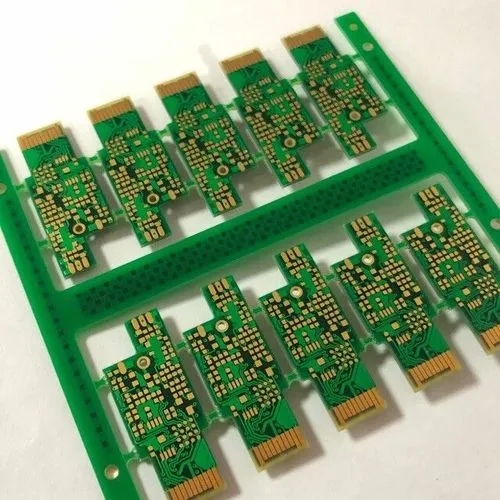

2. Process hole for producing pnl plate edge:

Ordinary multilayer circuit board: the inner layer is not drilled;

A: Rivets gh, aoi gh and et gh are all punched out after the plate is corroded

B: Target hole (drilling gh) ccd: the outer layer needs to be copper peeled, x-ray machine: directly punched, and note that the minimum length of the long side is 11inch.

Blind hole plate: all tooling holes shall be drilled, and attention shall be paid to rivets gh; It is necessary to pour out to avoid alignment deviation. (aoi gh also refers to beer production), characters shall be drilled at the edges of pnl boards to distinguish each board.

3、 Film modification:

1. Note that film produces positive film and negative film:

General principle: the plate thickness is greater than 8mil (without copper connection) and the positive process is adopted;

The plate thickness is less than 8mil (without copper connection);

When the line thickness and gap valley are large, the copper thickness at d/f should be considered instead of the bottom copper thickness.

For blind hole ring, 5mil is enough without 7mil.

The inner independent pad corresponding to the blind hole shall be retained.

Blind holes cannot be made without ring.

4、 Process:

The method of embedded hole board is consistent with that of ordinary double-sided circuit board.

Blind orifice plate, i.e. one side is the outer layer:

Positiving process: single side d/f shall be made, and the wrong side shall not be rolled (when the double side bottom copper is inconsistent); When d/f is exposed, the polished copper surface is covered with black tape to prevent light transmission.

As the blind hole plate is made more than twice, the thickness of the finished product is very easy to exceed the thickness. Therefore, the thickness of the blind hole plate should be controlled by the thickness of copper. The range of copper thickness should be indicated after etching.

After pressing the board, use the x-ray machine to make the target hole for the multilayer board.

Negative film process: thin plates (<12mil copper) cannot be produced by electric drawing, but must be produced by metal drawing, and metal drawing cannot apply current on one side separately, so it is impossible to apply no current on one side or reduce the current according to mi requirements. If the positive film process is followed, the copper thickness on one side is often too thick, which leads to etching difficulties and fine wires. Therefore, such plates need to use negative film process.

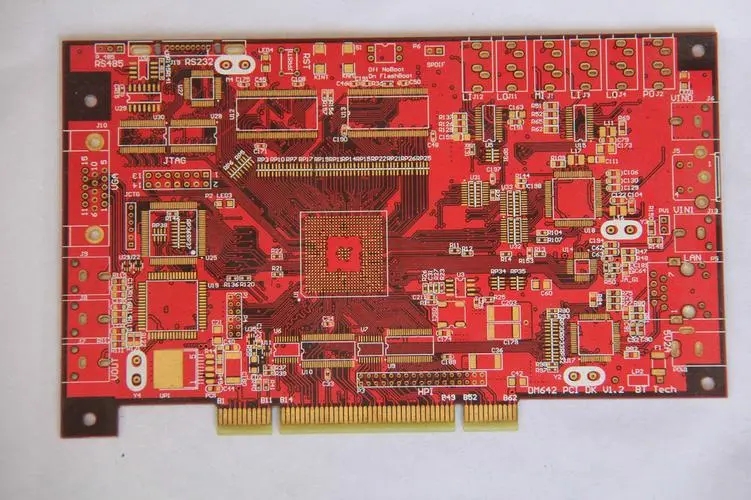

5、 The drilling sequence of through hole and blind hole is different, and the deviation is inconsistent during fabrication

The blind hole plate is easy to deform, and it is difficult to control the alignment of the multilayer plates and the pipe position distance when opening the horizontal and straight materials, so only the horizontal materials or the straight materials are opened when opening the materials.

6、 Laser drill

LASER DRILL is a kind of blind hole with its own characteristics:

Aperture size: 4-6 mil

Pp thickness must be <=4. 5mil, calculated according to aspect ratio <=0.75:1

There are three kinds of pp: LDPP 106 1080; FR4 106 1080 ; RCC 。

7、 How to define the need of resin plug hole for embedded hole plate

1. H1 (CCL): H2 (PP) >=4 thickness ratio

2.HI(CCL) 》32 MIL

3.2 OZ and above laser buried hole plate; Resin sealing is required for high thickness copper and high tg plates.

In the andante process of such boards, it is necessary to seal the holes with resin before making the circuit to avoid greater damage to the circuit. Circuit board manufacturing, circuit board design, PCBA processing manufacturers will explain to you the manufacturing of blind hole boards.