Main application aspects of PCB board and principle of multi-layer board layering

PCB is also called printed circuit board. Strictly speaking, printed circuit board is represented by PCB rather than "pcb board". Pcb is the electrical connection provider of electronic components and the core of electronic equipment, which can be any shape or size, depending on the application of electronic equipment. So, what are the pcb boards used for?

FR-4, as the most common substrate/substrate material of pcb, usually exists in many electronic devices and is also the most common intelligent manufacturing. FR-4 (PCB) is made of glass fiber and epoxy resin and combined with laminated copper cladding. Some of its main applications: computer graphics card, motherboard, microprocessor board, FPGA, CPLD, hard disk drive, RF LNA, satellite communication antenna feed, switch mode power supply, Android mobile phone, etc.

With the rapid development of printed circuit board industry, it plays an important role in medical equipment, industrial equipment, lighting, automobile and aerospace industries. The specific aspects of pcb boards are analyzed in the following sections.

1: Application of pcb in medical equipment

Nowadays, the rapid progress of medical science is closely related to the rapid development of the electronic industry. Many microbial equipment and other equipment are based on separate pcbs, such as pH meter, heartbeat sensor, temperature measurement, electrocardiograph, electroencephalograph, nuclear magnetic resonance imager, X-ray, CT scan, blood pressure machine, blood glucose level measurement equipment, incubator and other medical equipment.

2: Application of pcb in industrial equipment

Pcb is widely used in the manufacturing industry, especially those industries with high power mechanical equipment, which operates on high power and needs high current circuit drive. Therefore, it is necessary to press a thick copper layer on the upper layer of PCB, which is different from the complex electronic PCB. The current of these high-power PCBs is up to 100 amperes. This is particularly important in arc welding, large servo motor driver, lead-acid battery charger, military industry, clothing cotton machine and other applications.

3: Application of pcb in lighting

We can see LED lights and high-intensity LEDs around. These small LEDs can provide high brightness light and are installed on PCB based on aluminum substrate. Aluminum has the property of absorbing heat and dissipating it in the air. Therefore, due to high power, these aluminum circuit boards are usually used in LED lamp circuits for medium and high power LED circuits.

4: Application of pcb in automobile and aerospace industry

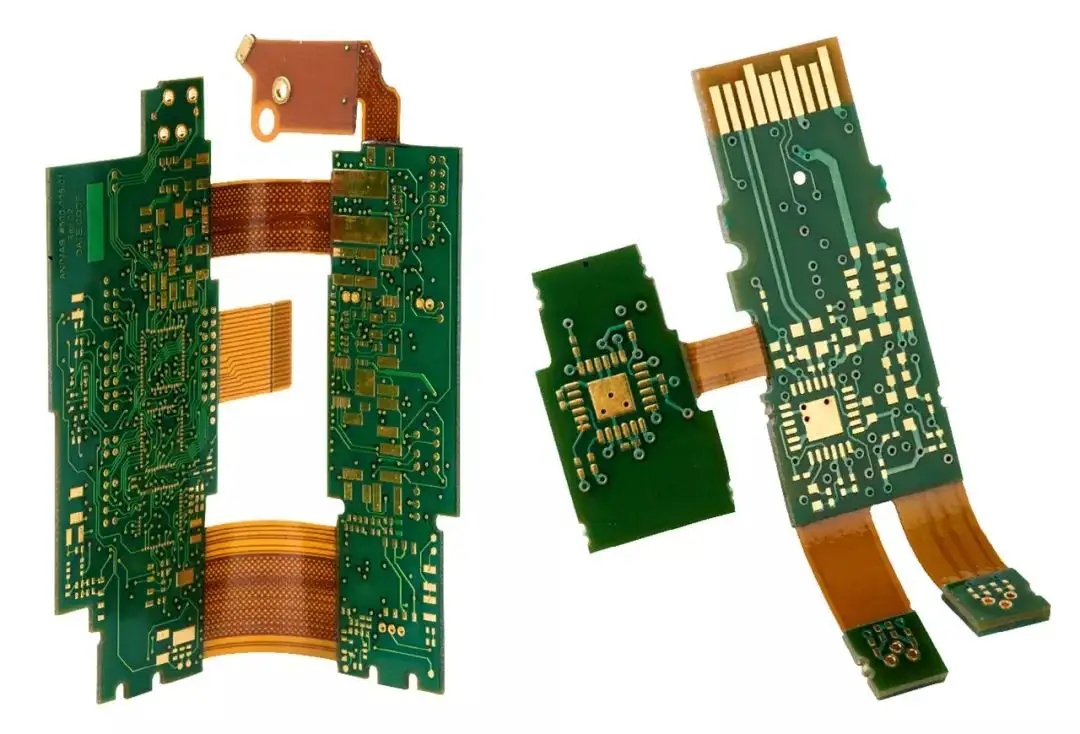

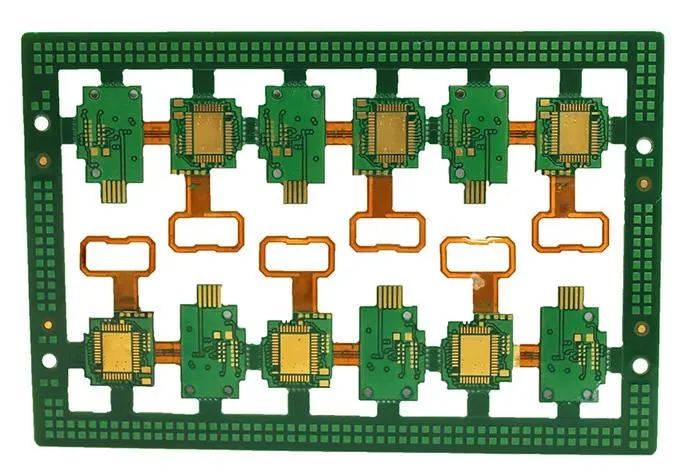

The most common reverberation generated by aircraft and cars in motion uses a PCB called Flex PCB to meet these high force vibrations and make PCB flexible. Flexible PCB is light, but it can withstand high vibration. Because of its light weight, it can reduce the total weight of spacecraft.

Even in the narrow space, flexible pcb can also be adjusted, which is a great advantage it occupies. These flexible PCBs are used as connectors and interfaces, and can be assembled even in a compact space, such as behind the panel and under the dashboard.

Explain the layering principle of PCB multilayer boards in detail

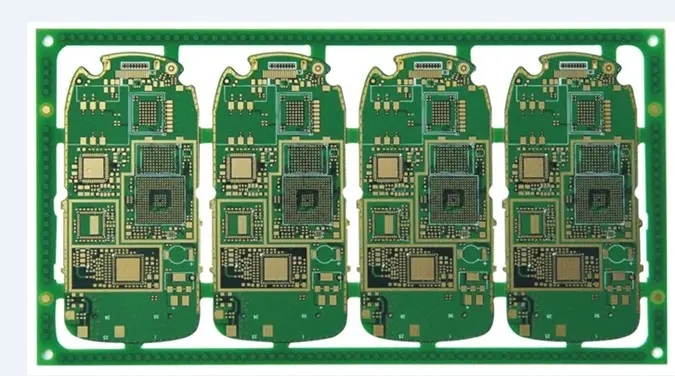

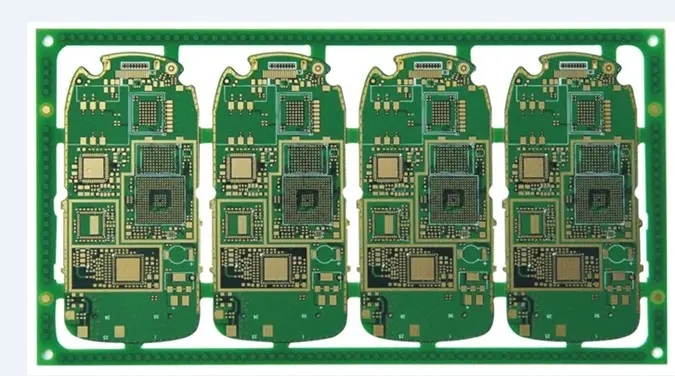

PCB board (printed circuit board) can be divided into single-sided, double-layer and multi-layer. There is no limit to the number of layers of multilayer boards. At present, there are more than 100 layers of PCBs, and the common ones are four layer and six layer boards.

The simple four layer board adds a power layer and a ground layer on the basis of the Top Layer and Bottom Layer, which greatly solves the problem of electromagnetic interference, improves the reliability of the system, improves the wire routing rate, and reduces the area of the PCB board.

The number of layers of the multilayer board is very flexible, and the designer can set it reasonably according to the actual situation. Then, what is the principle of pcb multilayer board layering? The setting of various layers shall meet the following requirements:

The power plane should be close to the ground plane, closely coupled with the ground plane, and arranged below the ground plane. The lower part of the element layer is the ground wire layer, which provides the device shielding layer and the reference layer for the top layer wiring;

2. The signal layer shall be adjacent to the inner electric layer, not directly adjacent to other signal layers. All signal layers shall be adjacent to the ground wire layer as much as possible;

3. Isolate the digital circuit from the analog circuit. If conditions permit, analog signal lines and digital signal lines shall be arranged in layers, and shielding measures shall be taken; If it is required to be arranged at the same signal layer, isolation strips and ground lines shall be used to reduce interference; The power supply and ground of analog circuit and digital circuit shall be isolated from each other and shall not be mixed.

4. When designing multilayer boards, each layer should be symmetrical, and it is better to use even copper layers. If it is asymmetrical, it is easy to cause distortion.

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the main application aspects of PCB and the principle of multi-layer board layering.