Take you into the secret of SMT steel mesh tension test of circuit board

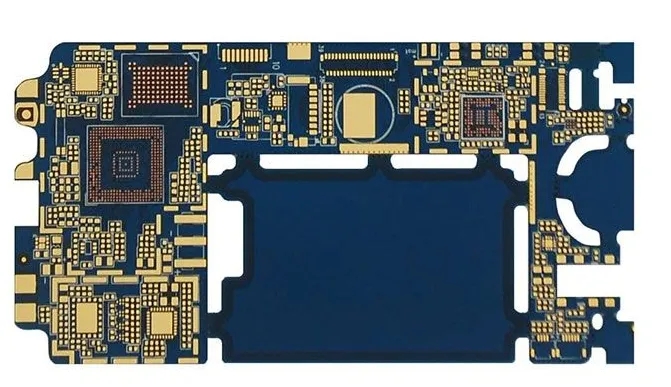

SMT chip refers to the abbreviation of a series of technological processes processed on the basis of PCB. PCB (Printed Circuit Board) is a printed circuit board.

SMT is the surface mounted technology (SMT), which is the most popular technology and process in the electronic assembly industry. The surface mount technology (SMT) of electronic circuits is called surface mount technology or surface mount technology. It is a circuit assembly technology that installs surface mounted components without pins or short leads (SMC/SMD, referred to as chip element device in Chinese) on the surface of printed circuit board (PCB) or other substrates, and then assembles them by reflow soldering or dip soldering.

In general, the electronic products we use are designed by pcb plus various electronic components such as capacitors and resistors according to the designed circuit diagram, so all kinds of electrical appliances need different smt chip processing processes

In the SMT chip processing process, the selection and use of stencil is directly related to the effect of solder paste printing, which determines the final welding result. In order to avoid less tin, continuous tin, false soldering, etc. during welding, SMT engineers must strictly control the steel mesh. This process includes: selection of steel mesh, tension test of steel mesh, cleaning of steel mesh, etc.

1. Selection of SMT steel mesh

The market price of steel mesh varies from 50 yuan to 500 yuan, representing different materials and manufacturing processes. At present, laser steel mesh is widely used, with a moderate price of 150-200 yuan. Copper mesh can be issued for those with higher requirements, or the price of manufacturers with higher precision capability will soar to 300-400 yuan. This depends on the mounting process difficulty of the customer's PCB.

2. Standard and method for tension test of SMT steel mesh

The steel mesh tension standard has reference indexes in the IPC electronic acceptance standard. Generally, a steel mesh tension tester is used, which is placed 15-20cm away from the edge. 5-8 points are selected, and the tension per square centimeter is greater than 35~50N. The tension must be re measured every time the wire mesh is used. The test steps are as follows:

Appearance inspection of steel mesh: whether there is scratch, burr, damage, etc

Zero the tensiometer and tighten the zero scale screw

The steel mesh shall be placed horizontally on the workbench, and it is not allowed to press the steel mesh with hands during detection

Select the test point and check whether the test value reaches the standard

Fill in the Steel Mesh Tension Test Record Form

Steel mesh cleaning

Installed and used on the solder paste printer

3. Cleaning of SMT steel mesh

After the stencil is installed on the solder paste printer, the cleaning cycle needs to be set. Some full-automatic solder paste printing and automatic cleaning function will be provided. Manual printing equipment requires workers to wipe every 4-10 boards after printing to avoid steel mesh plugging.

The test of steel mesh is often ignored by many small patch plants, which will inevitably cause unqualified steel mesh to be put into production, resulting in many defects in the welding of the rear section. In the SMT chip processing process, stencil and printing are the source of quality control and must be highly valued.

The circuit board manufacturer, circuit board designer and PCBA manufacturer explain the secrets of taking you into the circuit board SMT steel mesh tension test