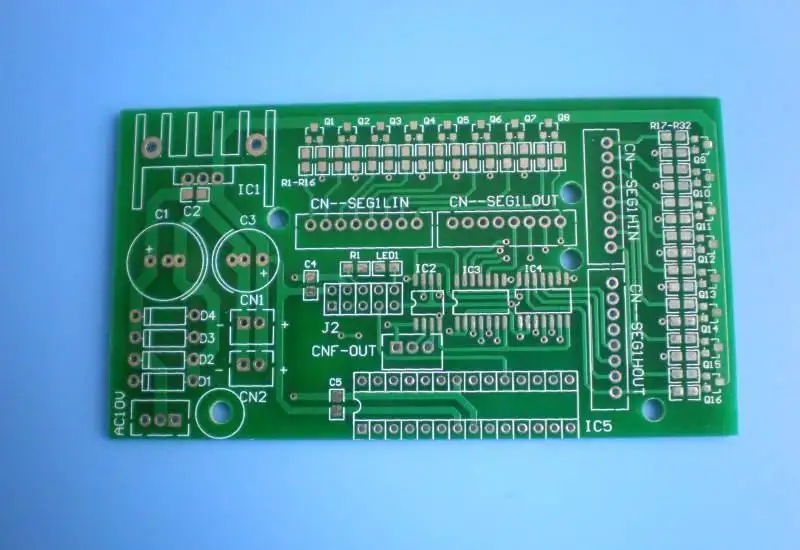

The quality of PCB affects the manufacturing quality of PCBA

PCBA manufacturing and processing is a very complex process. The whole PCBA processing seems to be only one word different from PCB, but actually the poor process is very different. PCBA needs to carry out a series of back-end processes on PCB, such as solder paste printing, SPI inspection, SMT processing, reflow soldering, DIP plug-in post soldering, wave soldering/selective wave soldering, PCBA first article detection, etc. These processes are not available in PCB.

However, just because all the following processes are operations on the PCB, the quality of the PCB determines the quality of the entire PCBA. What aspects of the PCB affect the PCBA? Let's share with you today.

1、 Dirty board surface

Dirty board surface is mainly caused by high solid content of flux, too much coating, too high or too low preheating temperature, or too dirty gripper of conveyor belt PCB, too much oxide and tin slag in solder tank, etc.

The main solution is to select appropriate flux; Control the flux coating amount; Control preheating temperature; Check the cleaning effect of the automatic cleaning PCB clamping claw and take measures; Clean the oxide and tin slag on the surface of the solder tank in time.

2、 White line remains

The white residue is commonly known as hoarfrost. Although it does not affect the surface insulation resistance, the customer does not accept it.

Solution: First use flux, then clean with solvent; If it cannot be cleaned, it may be due to the aging of the flux, or the absorption of water vapor when exposed to the air, or due to the excessive moisture content in the cleaning agent (solvent), or the mismatch between the flux and the cleaning agent, the supplier should be asked to assist in solving or replacing the flux and cleaning agent.

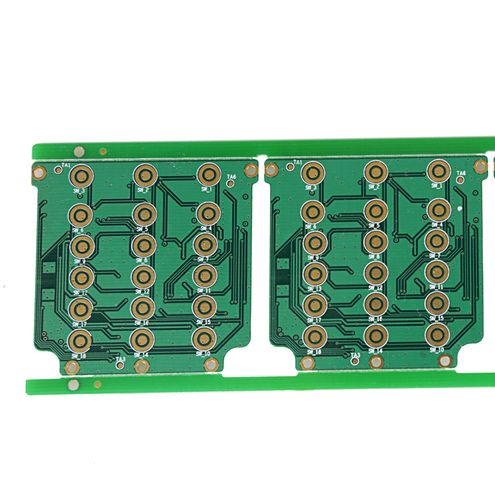

3、 PCB deformation

PCB deformation is mainly caused by large PCB quality or uneven component layout. When designing a PCB, try to make the components evenly distributed, and design a support belt in the middle of a large PCB (design a 2-3mm wide non layout component area); Or use a mass balanced tooling to press on the PCB where there are few components, so as to achieve mass balance during welding.

PCB manufacturing, PCB design and PCBA processing manufacturers will explain the impact of PCB quality on PCBA manufacturing.