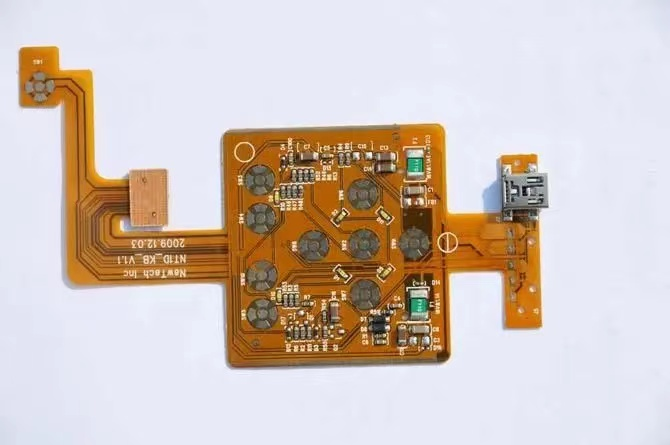

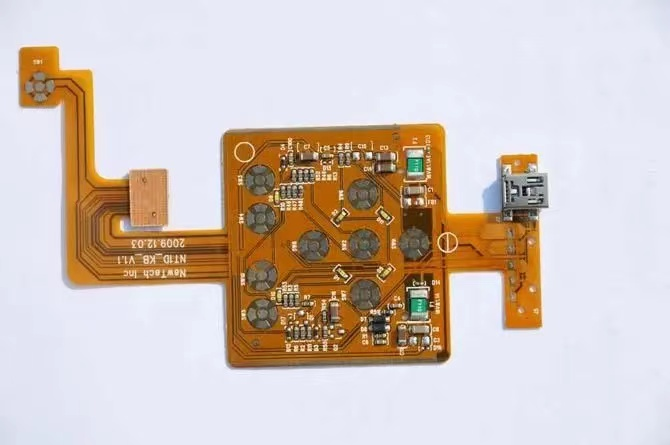

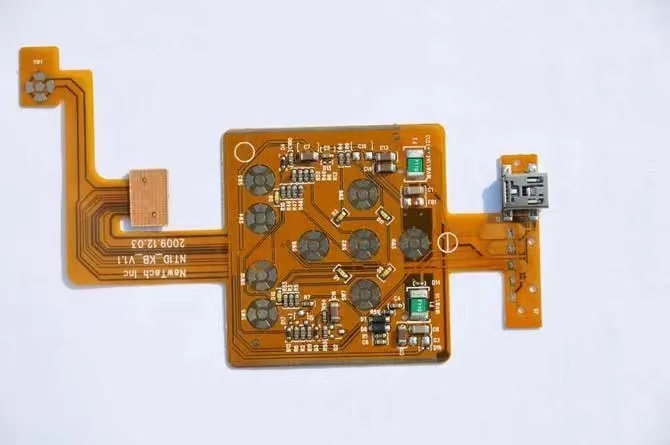

Flexible circuit board (FPC/softboard for short) The main growth point of the flexible circuit board market in the past two years is the digital products such as smart phones and touch screens. In particular, the demand for smart phones and touch screens has been increasing in recent years. Flexible circuit boards are mainly used in notebook computers, PNDs, digital cameras, e-books, DV, GPS, LCD TVs, plasma TVs, multimedia players and other products, The use frequency of FPC increases with the market's increasing demand for terminal products. Laptops and flat-panel TVs use a large number of LED backlights. FPC is usually the most common way to link LEDs with the main circuit board. In the future, the market demand for laptop screens and smartphones will continue to increase, as will the growth of FPC.

Tips for FPC beginners

Scope of exhibition

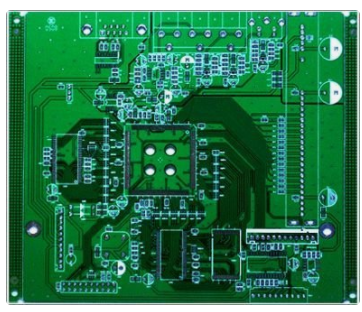

1. FPC flexible circuit board (flexible printed circuit board): single-layer board, double-layer board, multilayer board, FPC connector, double-sided board, etc;

2. FPC components: flexible copper foil substrate (flexible insulating base film and metal foil), flexible insulating layer (PI or PET protective film), release film, adhesive (glue), reinforcing plate or connector, etc;

3. FPC materials/materials: copper foil, reinforcement plate, conductive silver paste, silk screen printing ink, silicon aluminum foil, glass fiber cloth, silica gel/film, thermal tape, low-voltage pressure sensing paper, vacuum airbag, adhesive;

4. FPC process/testing equipment: bending machine, punching and drawing machine, hot/fast/rolling machine, covering film punching machine, false pasting machine, plate splitter, welding machine, peeling machine, UV curing equipment, exposure equipment, etching machine, screen printing machine, cutting and forming machine, mounting machine, testing and quality inspection equipment, etc.

5. FPC application industry: global 3G/smart phone, notebook computer, hard disk, printer, digital camera and display, touch panel and IC manufacturers, electronic product manufacturers, etc

Application fields of FPC soft board

The mature development of polymer materials has changed the bending of PCB, which can be roughly divided into three application fields:

1. The FPC soft board is divided into single, double and multilayer boards. Of course, different product names are generated according to the special process and structure.

2. The membrane switch is also divided into single and double layer circuits. However, most of the circuits are printed on the polyester film, which is combined with carbon ink printing, jumper and various key combinations to form a complete membrane type key for various instruments and equipment. At present, some blood glucose test tablets are made with this technology.

3. Plastic stereo circuit board is a product patent invented by an American company, but it is not widely used.

The die out interconnection component is also a stereo circuit technology, which is a stereo circuit structure product made on a plastic substrate that can be molded. At present, this technology is widely used in stereo antenna and automobile panel products, but it is not commonly used in other aspects.

Introduction to the Dust Sticking Machine in FPC Process

Electronic products are changing with each passing day. FPC requirements are also getting higher and higher with the development of products. The pressure of competition in the industry is intensifying, leading to vicious competition. Therefore, it is very important for the company to improve the yield of the product process. In FPC PCB process, foreign matter and dust particles have always had an impact on the product. Improving the above problems has been a topic for all PCB manufacturers at present, but many manufacturers have a large gap in determining dust removal and cleaning, In fact, the dust removal efficiency of many reused sticky dust machines is very low. Generally, it is 85-92%. There are many foreign matters and dust particles on the material surface, which will continue to affect the quality in the future. Our company has developed the latest FPC cleaner with different materials and cleaning rollers to achieve the best effect!