Electroplated coating on circuit board? Reliability of

(1) The coating defects produced in the manufacturing process, such as poor adhesion, gap or uneven coating.

(2) Poor connection caused by residue of glue. Finding problems depends on full understanding of the manufacturing process and quick feedback when they occur.

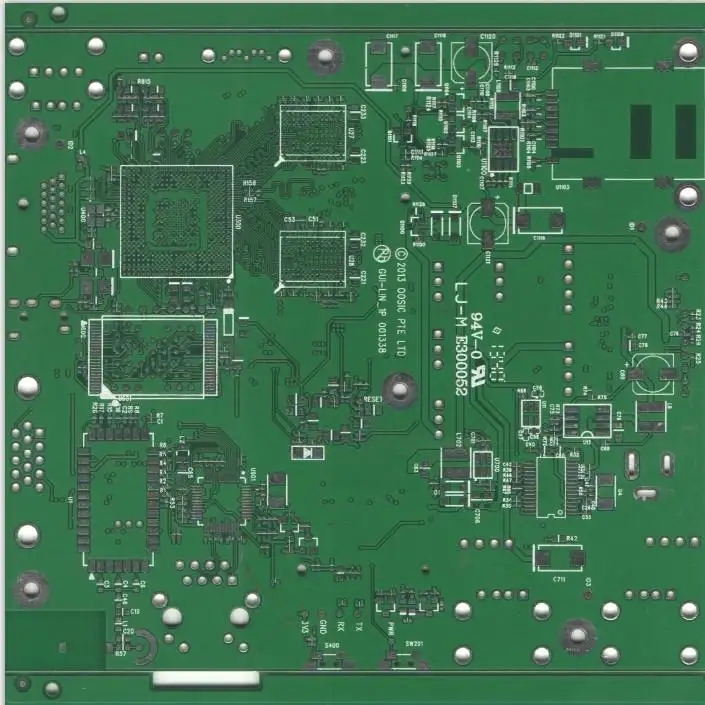

Most of the problems found in the reliability of through-hole plating are localized. In recent years, the replacement rate of electronic equipment is high, and the service time is not very long, so there is a relaxation in the setting of reliability. The so-called 10,000 to 20,000 hour service life is often heard. Most of them simulate the use of about eight hours a day, which can be used for more than three or six years. Due to the short history of high-density multilayer circuit boards, the long-term reliability data is still insufficient to fully reflect the reliability of actual products. Therefore, we can only make a moderate discussion on the limited information we know at present.

(A) Reliability of plated through-hole

The reliability of electroplated through-hole is discussed in many different products and application fields. An example of stress fracture of a circuit board at the corner of a hole after thermal stress testing. It has been proved from previous studies that the stress fracture of electroplated through-hole is related not only to the physical properties of the copper coating, but also to the geometric shape and size of the hole. Due to thermal expansion, different materials will have different deformation. Unbalanced deformation will pull the through-hole coating, so the inner layer of copper on the hole wall may be pulled off or peeled off.

Generally, the fracture is caused by cold and hot cycles. The test method is to simulate the actual equipment operation conditions by repeated fatigue stress tests using the stresses generated by thermal shock and thermal cycles.

When the circuit board is moving towards high-density and multi-layer, facing more complex assembly procedures, it is easy to make high-quality multilayer circuit boards by selecting appropriate resin materials and designing appropriate circuit board structures. In the past, the thickness of through-hole copper plating was mostly based on the minimum thickness of lmil. Recently, because the thickness of the plate remained in a low state with the appearance of the thin wire process, the thermal expansion change in the vertical direction was relatively small, so the coating degree was also relaxed.

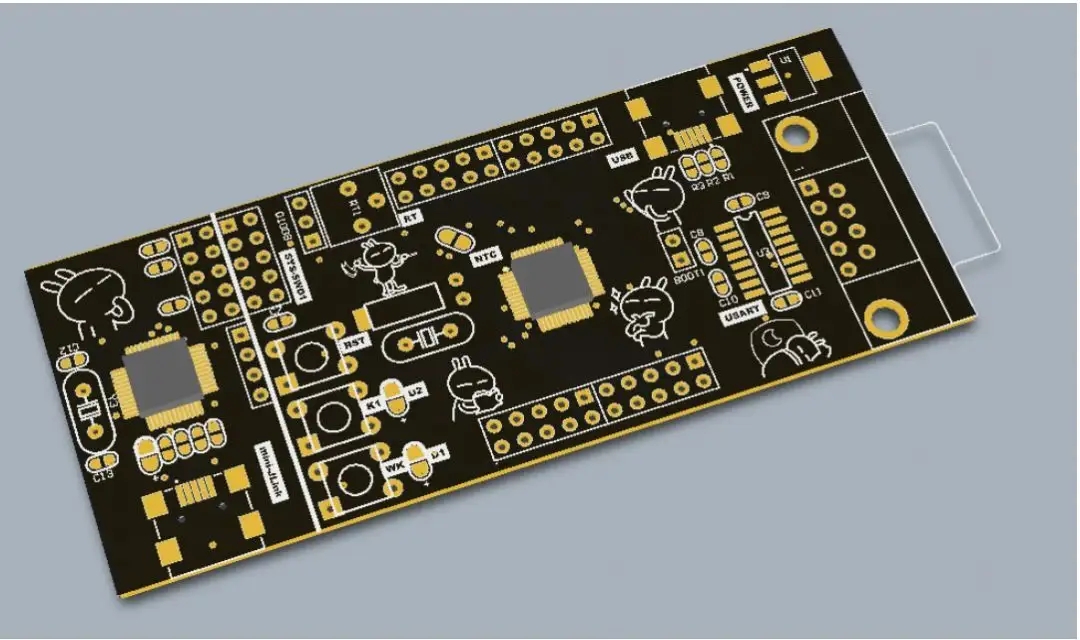

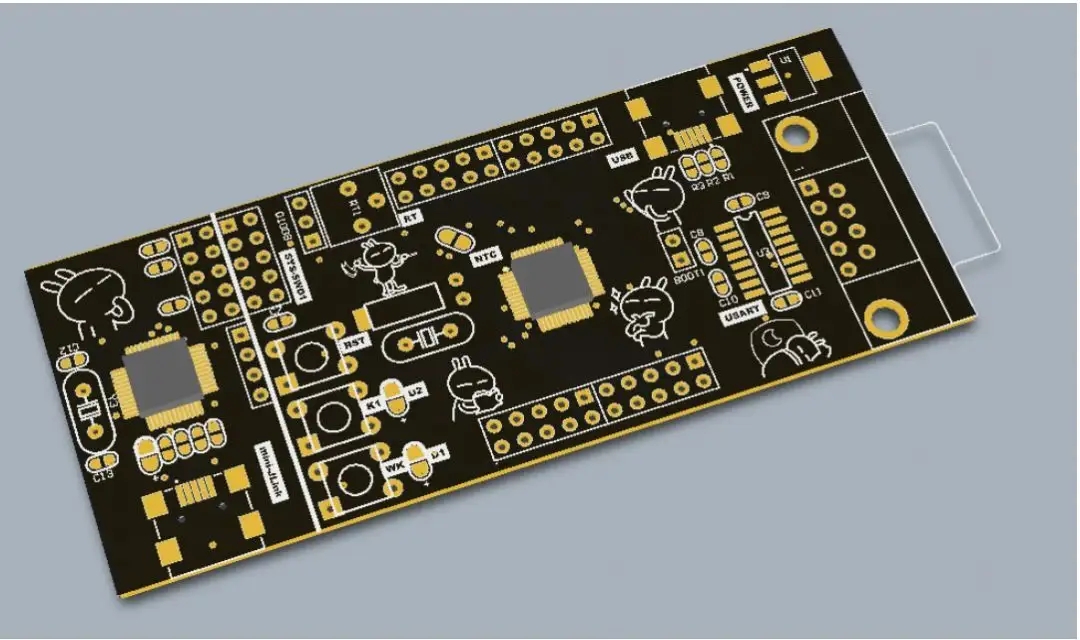

(B) Plating reliability of blind hole

The general depth design range of blind holes used in high-density multilayer circuit boards is about 30-100m. Compared with the traditional through-hole, the copper plating thickness can be relatively thin, generally defined as 10-20m. Due to the limited depth of the blind hole, the general problem is not at the corner of the hole, but because of the chemical copper treatment or laser drilling, the interface between the hole bottom and the copper pad breaks after the reliability test of the blind hole. For most of these reasons, there are more opportunities due to the insufficient cleanliness of the interface. Figure 2 shows an example of blind hole fracture after the reliability test.

More information has been accumulated on the construction of high-density multilayer circuit boards, which shows that such circuit boards still have good reliability.

(C) Relationship between adhesive residue and conductivity

In multilayer circuit boards, the quality of the connection between the electroplated through-hole coating and the inner layer is very important. The glue residue generated or remained during mechanical drilling or laser drilling will have a great impact on the integrity of the connection. Generally, the requirements for glue residue are almost the same, that is, no glue residue is allowed between the hole wall and the hole copper. After the current drilling process, the glue residue is generally removed, and the poor continuity caused by the residue of glue residue is rare. Of course, for the design with close hole spacing, excessive treatment of glue removal slag will lead to poor insulation. The manufacturer should not have the idea that the cleaner the glue removal is, the better. The amount of glue removal must be properly controlled. Of course, the best way is to improve drilling and reduce the production of glue residue.

(D) ) Reliability of connection between inner circuit and hole copper

The coating connected with the inner circuit, such as the connection between the inner copper layer of multilayer printed circuit board and the through-hole coating, and the connection between the blind hole of the laminated circuit board and the bottom circuit. If its reliability is poor, it is difficult to determine, and if it is already in use, the problem will become more complex.

Relevant items that affect the quality reliability include: pretreatment of inner copper in chemical copper, physical properties of chemical copper, physical properties of electroplating copper, etc. These items must be reviewed individually to control the problem.

In terms of chemical copper process, palladium, as the catalyst of chemical copper, is adsorbed on the wall of the through-hole hole and closely adsorbed to produce a uniform chemical copper coating. But in the part of inner copper layer, palladium has no binding force, so if it still exists between chemical copper and electroplating copper, it will hinder the combination of both. Therefore, the macroporous agent on the inner copper layer should be removed with micro etchant in advance to prevent palladium from being adsorbed.

When the chemical copper treatment is good and the production process of electroplating copper is started, attention should be paid to the cleanness of copper interface. Good cleanliness is the guarantee of electroplating quality.