Cleaning steps for solder joints of circuit board

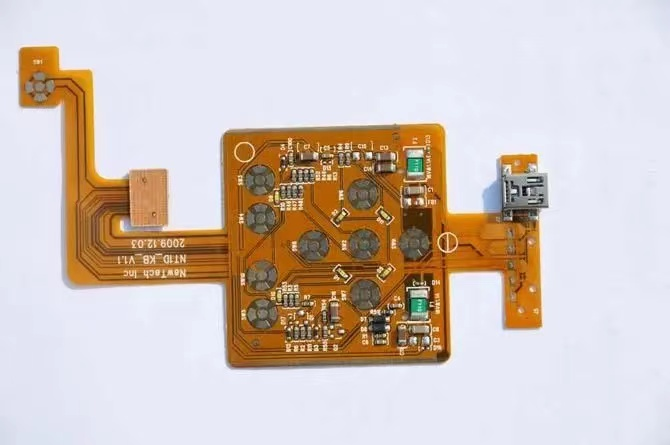

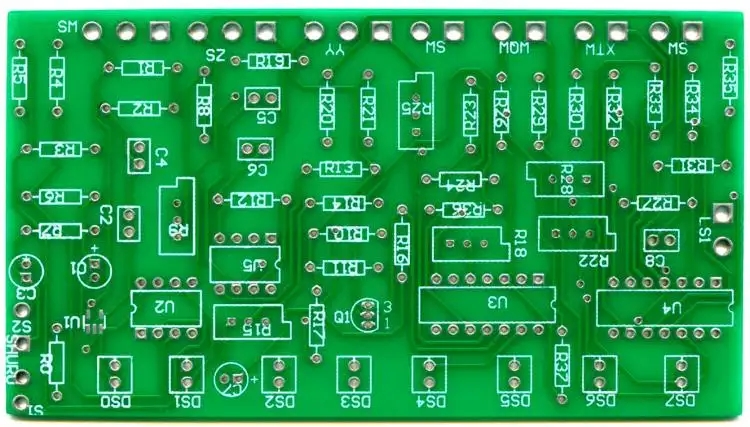

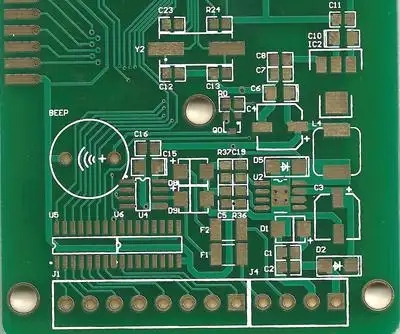

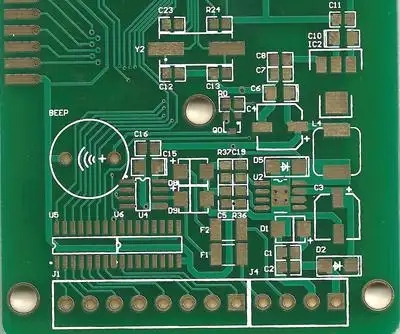

In the SMT patch processing process, because auxiliary agents such as flux are needed, some pollutants or spots will be generated after oxidation or high temperature, so many PCBAs need to be cleaned to be considered a perfect product.

In the SMT patch processing process, because auxiliary agents such as flux are needed, some pollutants or spots will be generated after oxidation or high temperature, so many PCBAs need to be cleaned to be considered a perfect product. In terms of cleaning, whether solvent cleaning or water cleaning is used, the pollutants shall be removed from the surface of the assembly plate by applying different mechanical forces through surface wetting, dissolution, emulsification, saponification, etc., and then rinsed or washed clean, and finally dried.

1、 Wet surface

The decontamination medium forms a uniform thin layer on the surface of the object to be washed, wets the surface of the object to be washed, and causes the pollutants on the surface of the object to swell. The condition of surface wetting is that the surface tension of the decontamination medium is less than that of the washed object. Adding some surfactants to the cleaning medium can obviously improve the wetting ability.

2、 Dissolution

The main decontamination mechanism of organic solvent cleaning is dissolution. The principle of similarity and compatibility shall be followed when selecting solvents. Polar solvents shall be used for polar pollutants and non-polar solvents shall be used for non-polar pollutants. However, polar solvent and non-polar solvent are often mixed in practical production. Adding some surfactants to the organic solvent cleaning can improve the solubility of the detergent to the line residues.

Introduction to cleaning steps and methods of PCB solder joints

3、 Emulsification

In the process of water cleaning and semi water cleaning, a certain amount of emulsifier can be added to the water. When cleaning synthetic trees, treating and receiving pollutants, these pollutants and emulsifiers will be emulsified and dissolved in water. The addition of surfactant can improve the emulsification.

4、 Saponification

Saponification is a simple chemical process and also a neutralization reaction. Lipid proof acid salt is used in the pen reaction, which makes rosin and neutral acid saponify, so that residues on the surface of the washed object can be dissolved in water and removed. Saponifiers will corrode aluminum and other metal surfaces. Therefore, when using saponifiers, corresponding grade etchants should be added, and the compatibility of saponifiers with components and other materials should be observed. Adding surfactant can promote saponification reaction.

5、 Chelation

Chelation refers to the addition of complex to dissolve insoluble substances (such as heavy metal salts).

6、 Apply mechanical force

Applying different mechanical forces can speed up cleaning and improve cleaning efficiency. ① Brushing, ② soaking, ③ spraying in air, ④ immersion spraying (jet cleaning), ⑤ centrifugal washing, ⑥ ultrasonic cleaning.