From the market to buy a companion textbook, because it is a edition, except for the introduction of the basic one or two pages can see errors. Because PLCC package was mainly promoted at that time, the pin number and pin number on the corresponding chip data manual of the same type of patch package were not consistent with the chip number...... Later to the outside company to do a project, "dare" to use this single chip microcomputer, surprised to find that this single chip microcomputer is still some temper, run to stop, stop when the internal is no longer a bit, it seems that the internal clock part is unstable... Later simply did not use this single chip microcomputer. Now think about it, in fact, the phenomenon of chip stop vibration is quite common, the crystal failure rate and the chip internal clock failure probability is relatively high.

I made two more on and off during my senior year, and then bought an ARM7 board (S3C4510). When buying did not care too much about the information, see the above resources are very much, the function is strong...... Later in the process of using a lot of problems, only to find that they provided the schematic diagram is rigged, with the board does not match. Moreover, since the board only carries one page of data and cannot directly use ADS(in order to prevent plagiarism, the FLASH data cable has been changed, and the command to start FLASH write operation has also changed), it takes too much time to learn, so up to now, this board has only been my "collection". Later, I found Jie Pai. I kept trying to improve my own board, making samples again and again and changing the design draft. I played once in three days and 4 times in half a month. Later, I could not help feeling "this is what the development board should have looked like".

Many of my classmates started to look for jobs in November, while I still focused on my studies. Even if I occasionally went to a job fair with my classmates, I could not send one or two resumes. On the one hand, my English is not good enough to meet the psychological needs of most enterprises... On the other hand, I think the senior year is a good opportunity to learn -- freshman, sophomore, junior almost finished all the * classes, the senior basically no classes, if you can use this year to learn the first three years of things a good system integration, there should be a great improvement.

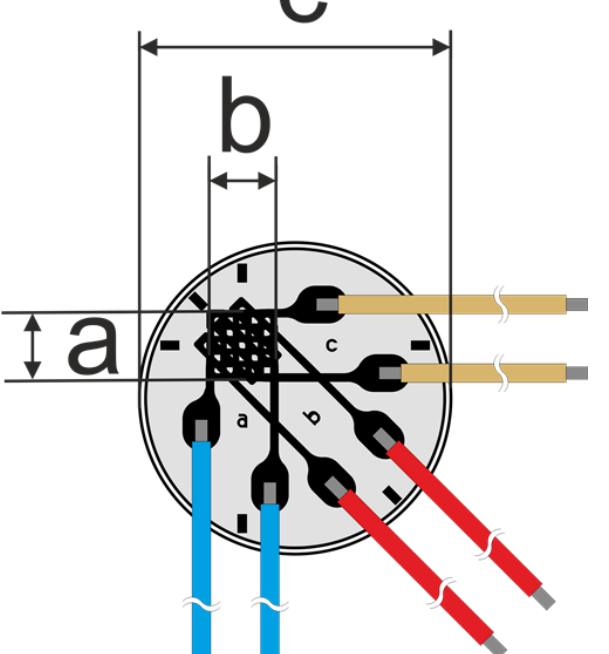

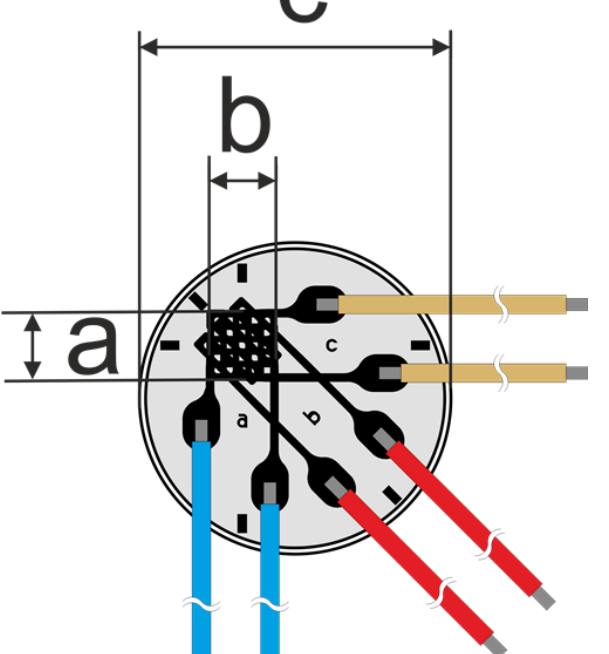

Small summary to recognize type switch | clamping overpressure device selection points:

Key points of ceramic gas discharge tube selection:

1. Voltage selection

Single use GDT: the arc voltage should be equal to the user's normal working voltage, and leave a certain margin.

Use with MOV: The DC breakdown voltage should be equal to the user's normal working voltage, and leave a certain margin.

2.GDT flow should be determined according to the lightning protection circuit design index, GDT flow should be greater than the lightning protection circuit design flow capacity.

Key points of semiconductor discharge tube selection;

1. The level of signal interface should be **Vs, with a certain margin.

2. Select TSS with different flow rates according to the level of surge to pass through.

3. The normal working current of the circuit cannot match the holding current of the TSS.

Key points of glass discharge tube selection:

1. The DC breakdown voltage should be equal to the user's normal operating voltage.

2. The flow rate of the glass discharge tube should be determined according to the design index of the lightning protection circuit. The flow rate of the glass discharge tube should be greater than the flow capacity of the lightning protection circuit design.

Key points of varistor/patch varistor selection:

1 pressure sensitive voltage to ** the user's normal working voltage, and leave a certain margin;

2. The flow rate of the varistor should be determined according to the design specifications of the lightning protection circuit. The flow rate of the varistor should be greater than the current capacity of the lightning protection circuit.

Key points of selection of transient suppression diode:

The breakdown voltage of S should be equal to the user's normal operating voltage, and leave a certain margin.

2. Use bidirectional or unidirectional TVS according to different application interfaces.

Dc power interface usually uses one-way TVS.

The AC power interface and communication interface generally use TVS in both directions.

3. TVS of different power should be selected according to the level of surge to be passed

Key points of ESD discharge diode selection:

1.ESD breakdown voltage to * the user's normal working voltage, and leave a certain margin.

2. Use bidirectional or unidirectional TVS according to different application interfaces.

The DC power interface is usually one-way.

The AC power interface and communication interface generally use TVS in both directions.

3. The higher the working frequency of the interface, the lower the capacity.

ESD discharge diode product selection ultimately or according to the specific needs of each customer to choose suitable ESD model. When selecting and improving solutions for customers, we must remember to follow the following two principles:

Vdrw≥ the operating voltage on the circuit

According to the application port, the protection level choose the chip varistor or diode, according to the transmission frequency choose the capacitance value, the higher the frequency, the lower the tolerance of the device, too large tolerance is easy to cause signal loss, therefore, must be according to their own needs to choose the appropriate ESD.