Surfacemount technology (SMT) is a new generation of electronic assembly technology developed from hybrid integrated circuittechnology. It is characterized by surface mounting of components and reflow welding technology. It has become a new generation of assembly technology for electronic products manufacturing.

The wide application of SMT promotes the miniaturization and multi-function of electronic products, and provides conditions for mass production and low defect rate production. SMT is surface assembly technology, which is a new generation of electronic assembly technology developed from hybrid integrated circuit technology.

The main components of the SMT production line are: surface assembly components, electric subgrade board, assembly design, assembly process;

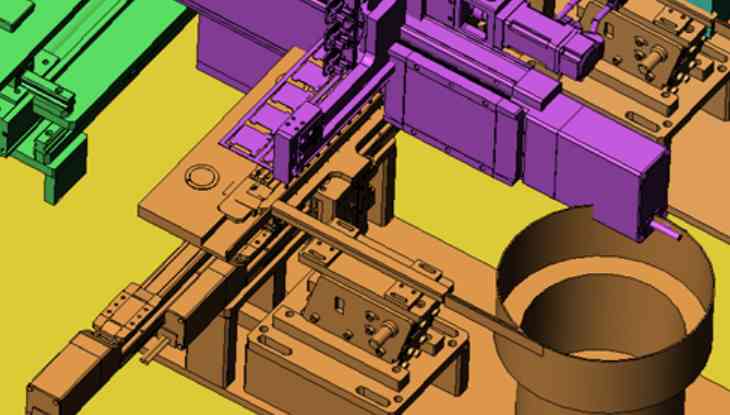

The main production equipment includes printing machine, dispensing machine, paste machine, reflow welding furnace and wave welding machine. The equipment includes testing equipment, repair equipment, cleaning equipment, drying equipment and material storage equipment.

By virtue of its strong technical strength, services, strict knowledge product protection measures and good business reputation, and relying on the perfect Internet trading platform, Fanyi has quickly become an important partner and support recognized by domestic and first-class enterprises. So far, Fanyi has expanded its business to the United States, India, Taiwan, Hong Kong and other regions and regions, and obtained Tensorcom, MR.LOOP, Ubilite, spChips and other nearly 100 foreign enterprises.

At present, there are many domestic PCB proofing factories, and customers often do not know how to choose when looking for a factory. What conditions should a good PCB proofing factory have, and how to consider PCB proofing factory? And so on, we will briefly introduce how to select the PCB proofing factory.

1. Pay attention to whether the factory information is true

In the Internet era, there is also a lot of information about PCB proofing factories on the Internet. When looking for PCB proofing factories, we should pay attention to the authenticity of information. There are many small workshops on the Internet that boast their own strength into large-scale and high-tech strength manufacturers, but in fact, there are indeed three workshops. In addition to searching information on the Internet, it is best to visit the factory, see the factory environment and assembly line, so as to choose the right manufacturer according to their own eyes.

2. Beware of price traps

The price is PCB proofing processing is a problem that most customers are more concerned about, due to regional issues, many customers are in the merchants for online pricing of PCB, formal manufacturers will have online quotation system, customers in the custom PCB proofing, do not cohabit cheap, so as not to customize the product quality is not up to the price.

3. Look at PCB proofing factory services

Good PCB proofing factory, of course, need to have good service. PCB proofing factory purchase needs to involve many issues, such as product process, product use, product warranty, etc., need to have a perfect service system. And the pre-sale service we can communicate with the manufacturer to see whether we can give customers detailed product introduction, whether we can be patient and solve customer problems. After-sales service is to see whether the manufacturer can provide package return, warranty, technology and other problems that may be encountered in the later period.

4. Pay attention to previous cooperation cases of PCB proofing factories

The strength of PCB proofing factory can often be reflected in its past cooperation customers. If many enterprises seek cooperation with this factory, its strength is not to be underestimated. The output and quality are relatively high.

Look for PCB proofing custom manufacturers, Fanyi PCB proofing factory! Fanyi has a series of features such as independent PCB online ordering, CRM management system, online self-quotation, self-ordering, online payment, online query of production schedule, express tracking and so on. Fanyi PCB proofing is a possible choice!

MSP430 MCU clock system

The MSP430 can optionally use up to three oscillators depending on the model. We can choose the appropriate frequency of oscillation according to the need, and can turn off the oscillator at any time when not needed to save power. The three oscillators are:

(1)DCO NC RC oscillator. It's inside the chip and can be turned off when not in use. The oscillation frequency of the DCO is affected by the ambient temperature and the working voltage of the MSP430, and the frequency generated by the same type of chip is different. But the adjustment function of DCO can improve its performance. Its adjustment is divided into the following three steps: a: select BCSCTL1.RSELx to determine the nominal frequency of the clock; b: Select DCOCTL.DCOx in the nominal frequency base segment coarse tuning; c: Select the value of DCOCTL.MODx for fine-tuning.

(2)LFXT1 is connected with low frequency oscillator. Typically, it is connected to a 32768HZ clock oscillator, at which time the oscillator does not need to be connected to a load capacitor. Can also be connected to 450KHZ~8MHZ standard crystal oscillator, at this time need to connect the load capacitor.

(3)XT2 is connected to a standard crystal oscillator of 450KHZ~8MHZ. In this case, you need to connect the load capacitor, which can be turned off when not in use.

Low frequency oscillators are used to reduce energy consumption, such as in battery-powered systems, and high frequency oscillators are used to respond to events or to perform heavy calculations by the CPU.