PCB design High speed backplane design and PCB layout skills

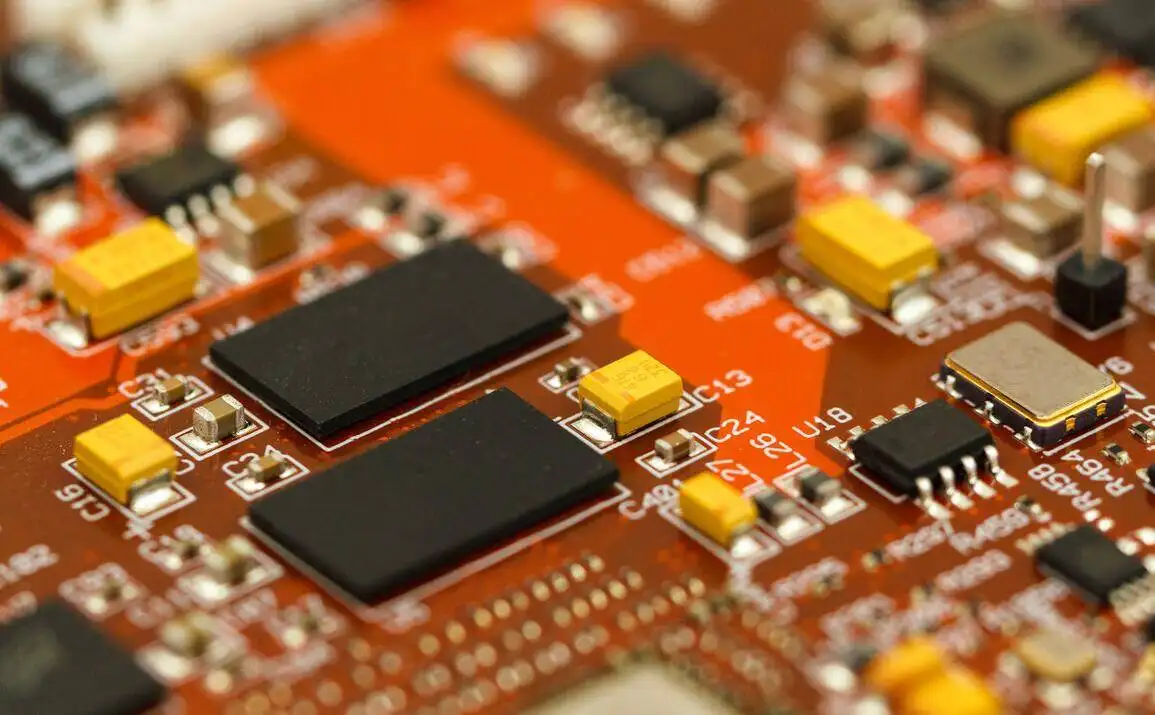

PCB design If you need to connect multiple boards to a larger system and provide interconnection between them, you may use backplanes to arrange these boards and cascade them. The backplane is a high-level board, which draws on some elements of high-speed design, mechanical design, high voltage/high current design and even RF design. These boards are typically used for mission critical defense systems, telecommunications systems, and data centers. They adopt their own set of standards, which exceed the reliability requirements of IPC.

Although the backplane follows specific standards that many other PCBs do not have, many PCB designers are familiar with the concepts involved in layout and wiring. At first, the large number of connectors and networks and the narrow space on a typical backplane seem difficult. Nevertheless, some simple strategies can help you maintain your organizational structure and complete the backplane design while ensuring high reliability. My hope is that you will learn some strategies for implementing the next backplane design in terms of cabling and layout to balance reliability and signal integrity. Without more content, let's jump into this rich field of PCB design.

Introduction to Backplane Design

Backplane design, pcb layout and cabling entry needs to take a variety of angles. These designs can be difficult because you may find yourself managing thousands of connections on large boards with limited space and layers. In addition, the backplane may actually participate in the power supply to the daughter cards, and each daughter card may be pulling multiple amps of current through various high-speed devices. This means that your backplane may need to support a current of about 100 A.

Since the main function of the backplane is to provide connections between multiple boards in a large system, everything revolves around the connectors you will use, and these connectors are the starting point for your design. The following are some basic tasks involved in backplane design:

Pin arrangement: The first step is to determine the pin arrangement on the connector to support the required routing topology. I will introduce this further below.

Mechanical requirements: In addition to the correct placement of the daughter board connector, the guide pin is also used to ensure the correct fit and structural integrity. The image at the bottom of the list shows a typical guide pin for use with backplane connectors.

Material selection: for high-speed backplane, this is the key point in the design process. Since the backplane can be very large, any signal that needs to travel across the entire plane can suffer significant losses. Low loss laminates with tight glass braids are required to minimize insertion loss on long interconnects.

Power and grounding strategies: For backplanes that need to provide high power for a large number of sub boards, you will need power and grounding strategies that help maintain low temperatures. The grounding/power plane layout on different plane layers shall also provide isolation for high-speed signals isolated on the circuit board.

Number of layers: The number of layers required for the backplane will depend on the number of plane layers and the number of signal layers required. The backplane can have 24 layers at most, with a thickness of several millimeters, which can meet all design requirements.

The above points are the same as those to be considered in any other high-speed line design. However, once you work on the backplane, the situation will be different, because the pin arrangement of the connector will limit the wiring. This is an important part of the backplane design and should be carefully planned.

All involve connectors, pin assignments and wiring

Most of the initial design phase will focus on the connectors on the backplane. Selecting connectors (including those for backplane) is both an art and a science. These connectors will become the main determinant of signal integrity. Simulation is important to ensure that the signal does not decay excessively at the connector tracking interface.

The pin arrangement in the connector is also important because it helps simplify the routing of each layer. In particular, your pin arrangement should achieve two goals:

It shall be designed to prevent signals on a given layer from crossing each other when they are routed to all connectors on the backplane bus. If done correctly, you may be able to eliminate some signal layers.

Ideally, when reaching the pins on each connector, the wiring should flow smoothly across the entire backplane (most levels).

It is better to do this line by line, similar to the differential pair routing shown below. Note how the pins on each connector are staggered in each column, allowing the routing in the differential pair to enter between the rows of connector pins. If all pins are in the same column, I need 2 layers instead of 1 for pcb wiring.

Considering all these design requirements, I found it difficult to achieve all these balances in my first backplane, and we did not even carry out the initial board component layout. You won't have much freedom in component layout, but as long as you arrange the pins in the entire connector and keep them consistent, you can keep things in order when routing signals through the backplane. Other tips to help you succeed include:

Minimize the jump of high-speed signal. Each through-hole will increase the insertion loss of the interconnection, and the insertion loss needs to be reduced as much as possible.

High speed reverse drilling through transition. Reverse drilling will increase costs, but will minimize stub line discontinuities on long transmission lines.

Don't be afraid to fall down. The use of grounding backflow helps to isolate between different high-speed wiring groups, ensure consistent impedance curves, and provide sufficient conductors for high return currents.

Make all unused signal layers plane layers. If you want to power through the backplane, do not worry about dropping additional power boards into the stack. Distributing current between multiple power layers helps keep the PDN cool.

The back panel design is not suitable for timid people, because it requires multiple majors to succeed. However, if you have the right team of designers and a complete set of design tools, you can complete most aspects of the design process on one platform. You will be able to complete the backplane design and prepare for pcb production through a program.