An important process in the production and manufacturing of flexible fpc soft boards is the process of covering film. The processing of fpc covering film is divided into three parts: 1. screen ripple printing of FPC covering layer, 2. FPC covering film, and 3. FPC photo coating layer. Let's take a closer look.

The processing of FPC coating film is divided into three parts:

1. Screen ripple printing of FPC coating

2. FPC covering film

3. FPC photo coating

Screen ripple printing of FPC coating

The mechanical properties of the missed print coating are worse than that of the laminated coating, but the material cost and processing cost are lower. Civil products and flexible printed boards on automobiles that do not require repeated bending are the most widely used. Its process and equipment are basically the same as that of the solder mask of rigid printed boards, but the ink materials used are completely different. The ink suitable for flexible printed boards should be selected. There are UV curing and heat curing inks in the market. The former has short curing time and is convenient, but its general mechanical properties and chemical resistance are poor. If it is used under bending or harsh chemical conditions, it is sometimes inappropriate to avoid using it for chemical gold plating, because the plating solution will penetrate into the coating from the end of the window, which will cause the coating to peel off in serious cases. As the curing of thermosetting inks takes 20~30min, the drying path for continuous curing is also relatively long, and intermittent ovens are generally used.

2. FPC covering film

The covering film is the earliest and most widely used technology for the covering layer of flexible printed boards. It refers to coating the same adhesive as the copper foil on the same film as the base film of the copper clad laminate to make it become a bonding film in the semi curing state, which is sold and supplied by the copper clad laminate manufacturer. When supplying, the adhesive film is pasted with a release film (or paper). The epoxy resin adhesive in the semi curing state will gradually cure at room temperature, so it should be refrigerated at low temperature. The printed circuit manufacturer should keep it in a refrigerated warehouse at about 5 ℃ before use or send it to the manufacturer before use. Generally, the manufacturer of PCB materials guarantees a service life of 3 to 4 months. If it is refrigerated, it can be used for 6 months. Acrylic adhesive hardly cures at room temperature. Even if it is not stored in cold storage, it can still be used for more than half a year. Of course, the laminating temperature of this adhesive must be very high.

One of the most important issues in the process of covering film is the liquidity management of adhesive. Before the covering film leaves the factory, the material manufacturer adjusts the fluidity of the adhesive to a specific range, which can guarantee a service life of 3 to 4 months under the condition of proper temperature and cold storage. However, during the validity period, the fluidity of the adhesive is not fixed, but gradually decreases with time. Generally, due to the great fluidity of the adhesive, the adhesive is easy to flow out of the coating film just leaving the factory and pollute the terminal and the connecting plate during lamination. At the end of its service life, the adhesive has very little or no fluidity. If the laminating temperature and pressure are not high, it will not be able to get a covering film that can fill the gaps in the pattern and has high bonding strength.

The covering film shall be processed by opening the window, but it cannot be processed immediately after being taken out of the cold storage. Especially when the ambient temperature is high and the temperature difference is large, the surface will condense. When the base film is polyimide, it will also absorb moisture in a short time, which will affect the subsequent process. Therefore, the roll shaped covering film is generally sealed in a polyethylene plastic bag. The sealing bag should not be opened immediately after it is taken out of the refrigerator, but should be put in the bag for several hours. When the temperature reaches room temperature, the covering film can be taken out of the sealing bag for processing.

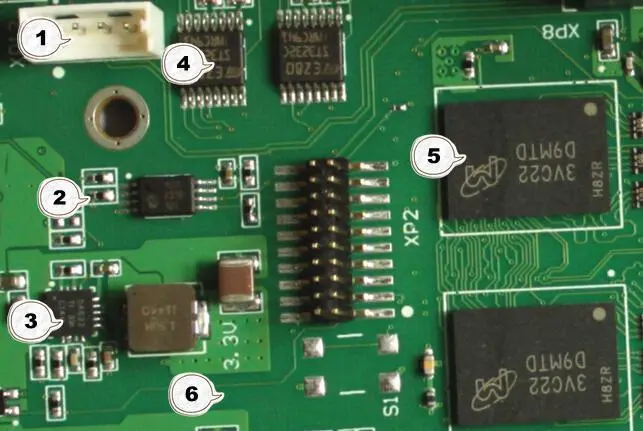

The covering film opening window uses a CNC drilling and milling machine or a punch, and the rotation speed of PCB CNC drilling and milling cannot be too high, which is high in operating costs. This method is generally not used in mass production. Overlap 10-20 sheets of covering film with release paper, fix them with upper and lower cover backing plates, and then process them. The semi curing adhesive is easy to attach to the drill bit, resulting in poor quality. Therefore, it should be inspected more frequently than when drilling copper foil, and the debris generated during drilling should be swept away. A simple die can be used to process the window of the covering film with the punching method, and the punching die can be used to cut the batch holes with a diameter of less than 3mm. When the hole of the window is large, the die is used. Small holes in small and medium batches are processed with a combination of CNC drilling and die. The processing of the covering film is shown in Figure 10-8.

Remove the release film from the cover film with the window holes, and then paste it on the substrate with the circuit etched. Before lamination, clean the circuit surface to remove the surface pollution and oxidation. Chemical method for surface cleaning. After removing the release film, there are many holes of various shapes on the covering film, which completely becomes a film without a skeleton, which is particularly difficult to operate. It is not easy to use the positioning hole to overlap with the position on the line. At present, mass production plants still rely on manual positioning and lamination. The operators first accurately locate the covering film window hole and the connection panel and terminal of the line graph, and then temporarily fix them after confirmation. In fact, if the size of either side of the flexible printed board or the covering film changes, it cannot be accurately positioned. If conditions permit, the covering film can be divided into several pieces and then laminated for positioning. If the covering film is forcibly stretched for alignment, the film will become more uneven and the size will change greatly, which is an important reason for the wrinkling of the plate.

For temporarily fixing the covering film, electric soldering iron or simple pressing can be used. This is a process that depends entirely on manual operation. In order to improve the production efficiency, various factories have come up with many methods.

The fixed covering film shall also be heated and pressurized to make the adhesive completely solidified and integrated with the circuit. The heating temperature of this process is 160~200 ℃, and the time is 1.5~2h (a cycle time). In order to improve production efficiency, there are several different schemes, the most common one is to use a hot press. Put the printed board with the covering film temporarily fixed between the hot plates of the press, overlap them by sections, and heat and pressurize them at the same time. The heating methods include steam, thermal medium (oil), electric heating, etc. The cost of steam heating is low, but the temperature is basically 160 ℃. Electric heating can be heated to more than 300 ℃, but the temperature distribution is uneven. The silicon oil is heated by an external heat source. The temperature can reach 200 ℃ by using silicon oil as the medium, and the temperature distribution is uniform. Recently, this heating method has been used more and more. Considering that it is ideal to use vacuum press to make the adhesive fully fill in the gap of the line pattern, the equipment price is high and the pressing cycle is slightly longer. However, it is cost-effective to consider the qualification rate and production efficiency. The examples of introducing vacuum press are also increasing.

The way of laminated board has a great influence on the state of adhesive filling between lines and the bending resistance of finished flexible printed boards. Laminated materials are available for general use in the market. Considering the cost of mass production, each flexible plate factory makes its own laminated materials. According to the structure of flexible printed boards and the materials used, the materials and structures for laminated boards are also different.

3. FPC photo coating

The basic process of the photo induced coating is the same as that of the photo induced solder mask used for rigid printed PCB boards. The materials used are also dry film type and liquid ink type. In fact, there are differences between solder mask dry film and liquid ink. Although the coating process of dry film and liquid ink is completely different, the same device can be used for exposure and subsequent processes. Of course, the specific process conditions will vary The dry film shall be pasted first, and all the circuit diagrams shall be covered with dry film. The ordinary dry film pasting method is easy to have bubbles left between the lines, so a vacuum film applicator shall be used.

The ink type is to use screen printing or spraying method to coat the ink on the line graphics. Screen printing is a relatively common coating method, which is the same as that of rigid printed boards. However, the thickness of the ink for the first missed printing coating is relatively thin, which is basically 10~15um. Due to the squareness of the line, the thickness of the primary printing ink is uneven, and even skip printing occurs. In order to improve reliability, the second missed printing should be carried out after changing the direction of the missed printing. The spraying method is a relatively new technology in the process of printed boards. The spraying thickness can be adjusted by using the nozzle, and the adjustment range is also wide. The coating is uniform, and there are almost no parts that cannot be coated. It can be coated continuously, which is suitable for mass production.

The ink used for screen skip printing includes epoxy resin type and polyimide type, both of which are two-component. Before use, they are mixed with curing agent, and solvent is added to adjust viscosity as required. After printing, they need to be dried. Double sided lines can be coated on one side for temporary drying, and then coated on the other side for temporary drying. After exposure and development, they can be dried and cured.

The pattern exposure of the photo induced coating requires a positioning mechanism with a certain accuracy. If the size of the disk is about 100um, the position accuracy of the coating is at least 30-40um. As discussed during the graphic exposure, if the mechanical capability of the device is guaranteed, this accuracy requirement can be achieved. However, after the flexible printed circuit board is processed by the multi-channel PCB design process, it is difficult to meet the higher requirements due to the expansion or partial deformation accuracy of its own size.