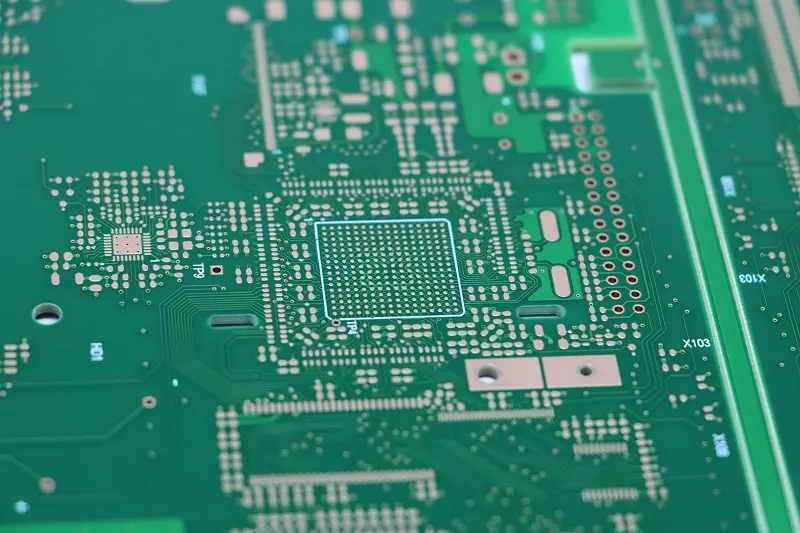

Share and explain the secrets of excellent PCB design

In order to achieve excellent design, a disciplined approach is needed to keep PCB reliability at the forefront of the design process. If the circuit board fails prematurely due to low-level components or inability to solve peak current and power requirements, the performance of the PCB will not be greatly affected. The comprehensive and excellent design has prepared for the comprehensive and successful production of PCB, and enabled the prototype PCB to verify its manufacturability and testability. Reliability first attitude will provide the performance you want at a reasonable price.

Secret 1 – Details of component selection

As mentioned earlier, functional performance is not a driver for component selection. We can attribute this to the increasing complexity of the available components. There are more external factors that determine the service life of these equipment, and they are related to reliability, which is why it is so important to design reliability in advance. So, what are these external factors?

All these will affect the life of the parts. If the operating environment does not meet strict standards, it may lead to premature failure. There are many factors leading to these problems. We will mention some effects here, but the list is much longer. In some cases, the problem boils down to that you don't know what you don't know. Circuit board assembly and circuit board processing manufacturers explain and share the secrets of achieving excellent circuit board design.

Let's take MSL as an example. The standards that exist as guidance are incomplete. J-STD-020D is only applicable to surface mount technology (SMT) packaging with integrated circuits. It does not include passive components or wave soldering. If the component manufacturer does not provide you with the MSL of the component, you can determine its characteristics. That is the physical process of failure (PoF). Most standard components have a maximum MSL of 3.

The damage that may occur when the MSL limit is exceeded is called popcorn, because you will cause PCB cracking and delamination due to the absorption of moisture in the dielectric material. The damage sounds like popcorn popping. Usually, this happens when the PCB is not packaged and stored correctly.

Secret 2 – A rule of thumb to replace PoF

In all these cases, the risk must be assessed. If the risk of failure is too high, the rule of thumb should be ignored for PoF calculation.

Secret 3 – Reliability Design

The best practice is to predesign reliability rather than devoting all your energy to performance design. Your performance goal will be achieved in this process, because the high reliability components you want to select will provide the performance you want in a longer time. Your customers will be twice as happy. Why? First, you will reduce production costs. If you think theoretically, you will defeat the failed physical theory.

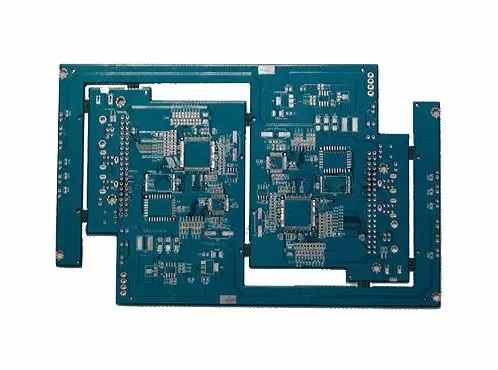

Secret 4: Communication between production teams in the design stage

This secret is a common sense problem, but you will be surprised to find that it is often confused, leading to costly mistakes. From a design perspective, the two roles in the team must be handled correctly. The primary responsibility of the electrical engineer is to design the component structure of the circuit to be placed on the PCB. His/her job is to obtain the bill of materials (BOM) correctly and prepare the approved supplier list (AVL). Reliability and performance depend on its high quality. The second role is the mechanical engineer (today's electrical engineer usually takes the role). He will determine the layout of PCB, including all conductive paths (wiring), vias (holes on the circuit board) and the preparation of the circuit board. This welding work will be first-class.

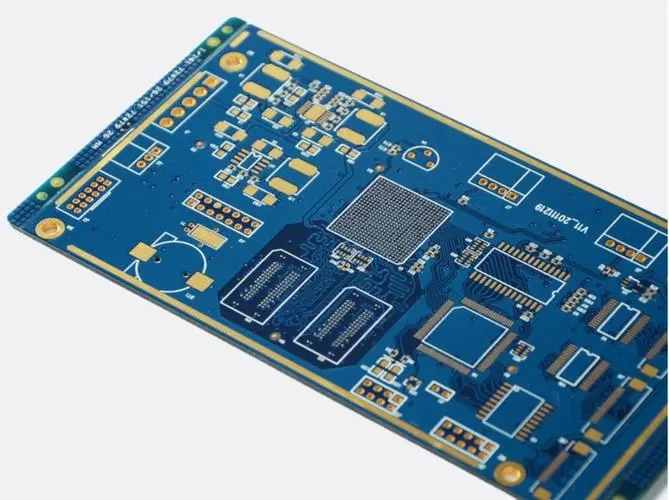

Organizing the production team is a good time to bring PoF into the discussion, because it illustrates the importance of Secret 1 and the mechanism that makes Secret 2 valuable. Reliability is not an accurate science, but PoF can measure the physical reliability involved in PCB production. PoF is a general term to some extent, including chemistry and physics, to understand the failure mechanism of electronic components (including semiconductor devices). The scientific achievement of PoF is to estimate the service life of circuit components under actual working conditions. This also shows the importance of understanding the reliability of circuit components.

This article only outlines all reliability issues to consider. Avoid the design errors discussed at the beginning of this article, and avoid taking reliability into account when designing. The performance will follow. Maximize your understanding of PCB design considerations and practice design at every opportunity to achieve excellence.