PCB design rule check reduces the pin of the circuit board

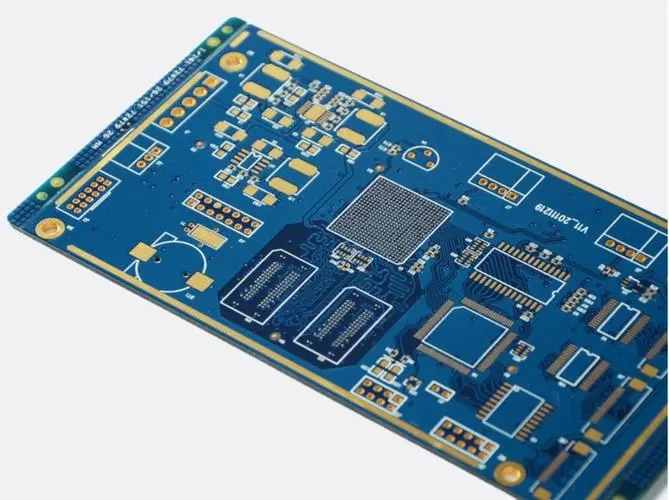

The design of printed circuit board is based on the circuit schematic diagram to realize the functions required by the circuit designer. The design of printed circuit board mainly refers to layout design, which needs to consider the layout of external connections. The optimal layout of internal electronic components, the optimal layout of metal wiring and through-hole, electromagnetic protection, heat dissipation and other factors. Excellent layout design can save production costs and achieve good circuit performance and heat dissipation. Simple layout design can be realized by hand, while complex layout design needs to be realized by computer aided design (CAD)

PCB designs usually undergo multiple reproductions due to the results of inconspicuous signal integrity (SI), power integrity (PI), and electromagnetic interference (EMI) violations. The average cost of each redesign is expensive, so it is imperative to ensure that a given design meets its performance, time to market and cost objectives. To help eliminate complex and difficult to diagnose layout violations, some PCB tool kits provide a unique Electrical Design Rule Check (DRC).

When DRC analysis is used as part of the PCB design process, engineers can ensure that their PCBs meet the appropriate constraints of many different high-level electrical design rules. The DRC tool contains fully customizable SI, PI, EMI and safety rule checks, enabling designers to quickly identify and correct violations before starting the manufacturing process. By running DRC analysis, you can eliminate error prone manual checks and reduce costly design rework, which will affect the time to market of the product and the profitability of the company.

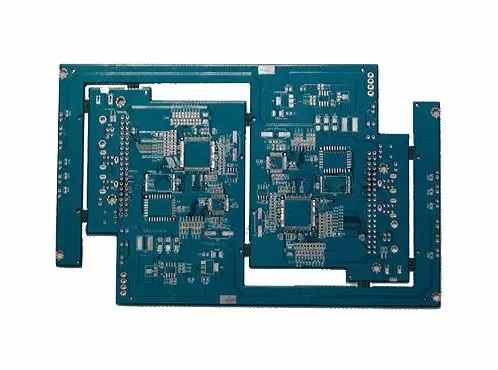

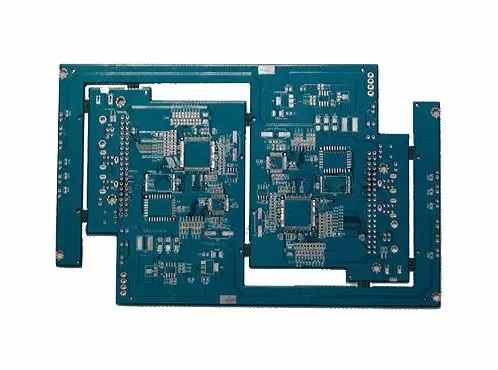

To illustrate the powerful function of using PCB design tools with tightly integrated DRC analysis, we will take BeagleBone Black as an example. BeagleBone Black is a low-power, open source, single board computer produced by Texas Instruments (TI), widely used by developers and amateurs. The development board is composed of TI Sitara processor, which can provide a combination of performance, power and peripherals to help reduce system cost, simplify design and expand connectivity in the entire BeagleBone Black design. In addition to the TI Sitara processor, the board also includes 512 MB DDR3 RAM and 2GB flash memory, as well as many physical interfaces and other functions.

Tightly linked DRC and PCB layout interface

Because the layout and DRC tools are fully integrated, PCB designs can be loaded into DRC directly from the PCB layout window. The rules in DRC are divided into specific categories - SI, PI, EMI and security. Each individual rule contains a descriptive overview page that allows designers to easily select the most important tests to run on their PCB layout. PCB assembly and PCB processing manufacturers explain PCB design rules and check to reduce PCB pins.