Classification basis for PCB design engineers: entry-level PCB engineers, junior PCB engineers, intermediate PCB engineers (can be subdivided into A, B, and C levels according to individual specific capabilities, with A being the highest, followed by B), and senior PCB engineers.

Position: entry-level PCB engineer

Capability requirements:

1. Can make simple sound package, such as DIP10;

2. Master the basic operation of at least one PCB design software, and be able to formulate simple rules such as wiring line width and spacing;

3. It is able to carry out more reasonable and orderly layout and wiring for PCB with 100 components and 200 networks or less;

4. It can be manually or automatically wired and modified under other people's or self defined rules to achieve 100% routing and DRC pass completely;

5. Basic knowledge of mechanical structure and thermal design;

6. Master some basic requirements for double-sided board wiring.

job content:

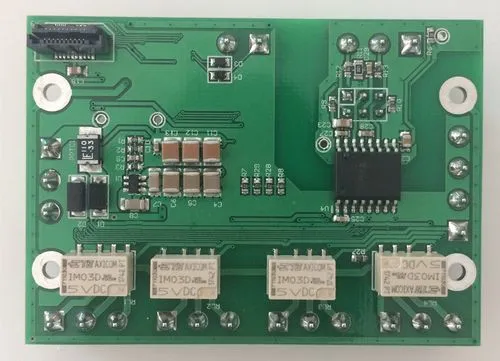

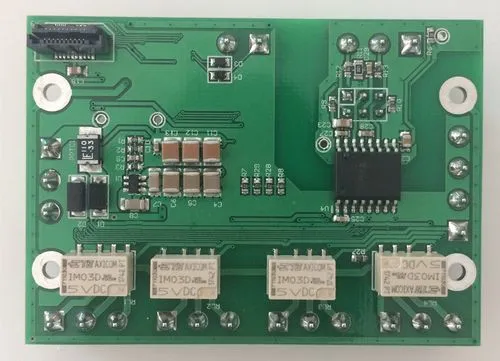

1. Design and modification of simple PCB (such as front panel with simple structure, small system board of single chip microcomputer, etc.);

2. Wiring of specified parts in complex PCB;

3. Debugging related to self-designed PCB;

4. Write relevant development and debugging logs.

Responsibilities: Responsible for the self design part of PCB.

Position: Junior PCB Engineer

Capability requirements:

1. Be able to make complex packages, such as RJ-45 seats with lights, according to the manual and physical objects, and ensure that the shape, pad and other dimensions are completely correct (at least it can be inserted according to physical objects);

2. Be familiar with at least one PCB design software and be able to formulate detailed wiring rules independently or under guidance;

3. Be able to carry out reasonable and orderly layout and wiring of single, double and multi-layer PCBs with 400 components and 1000 networks or less, and take into account the requirements of thermal design, structural design, electromagnetic compatibility design, aesthetics and other aspects at any time in the layout and wiring process. If you can't be sure, you can consult or discuss with a higher level PCB engineer in time;

4. Be able to skillfully route and modify manually or automatically under other people's or self determined rules, and achieve 100% routing and DRC pass completely. There are basically no problems such as line width bottleneck, inner layer islands, etc. During the routing process, a small number of low-level errors in principle design can be seen and raised, and the pins and doors can be exchanged correctly, and the network table and schematic diagram can be modified correctly;

5. Can correctly import and export mechanical drawings and basically understand the structural dimension requirements;

6. Be able to carry out some high-speed and analog PCB design under the rules or guidance of others and basically stable;

7. The silk screen mark is clear and clear, and can independently complete GERBER and other design output work and proofread;

8. Have basic knowledge of manufacturability and use it in practice, and more than 50% of the designed boards can be used in production.

job content:

1. Design and modification of more complex PCBs (such as boards other than CPU boards in the scheduling machine, 16 screen splitter boards, etc.);

2. Wiring of specified parts in complex PCB;

3. Debugging related to self-designed PCB;

4. Work guidance for all lower level PCB engineers;

5. Write relevant development and debugging logs;

6. When necessary (it means that you have no corresponding design task for a certain period of time, or a PCB design work time is urgent, and you must transfer or strengthen the designers, the same below), take any low-level PCB engineer's job.

Responsibilities: Responsible for the self design part of PCB.

Job position: Intermediate PCB engineer (can be divided into three grades: A, B and C according to individual specific ability, with A being the highest, followed by B)

Capability requirements:

1. Be able to fully understand various original device manuals and wiring manuals, independently make extremely complex packages, such as placing switches, and ensure that various capabilities are completely correct (at least ensure insertion according to physical measurement), and be able to find appropriate devices or replacements according to principles and structural requirements;

2. Master the operation and skills of at least one PCB design software and be able to formulate detailed wiring rules;

3. Be able to put forward opinions on the division and integration of various functional blocks according to the system requirements, be able to reasonably arrange and route all functional blocks independently or according to the division of labor for PCB of any number of components and networks, and be able to consider the requirements of thermal design, structural design, SI, PI, EMC, aesthetics, manufacturability and other aspects at any time during the layout and routing process and propose solutions, Be able to provide some requirements and rule references in layout and wiring for entry-level and junior PCB engineers;

4. Be able to correctly design the laminated structure of the board, and reduce the number of layers and cost as much as possible while meeting the performance requirements;

5. Have more knowledge of high-speed and analog PCB design in terms of impedance, time delay, overshoot, crosstalk, loop, signal loop, plane integrity, inner layer division slot, signal termination, etc., be able to complete SI simulation and analysis of key signals and areas independently or under the guidance of SI engineers, etc., and put forward suggestions for improvement;

6. Be able to skillfully route and modify manually or automatically driven by rules. The whole board has a certain aesthetic feeling. More than 80% of low-level errors in the principle design can be seen and put forward during the routing process. Be able to skillfully and correctly exchange pins and gates;

7. Excellent communication with the principle and structure design engineers, understanding more complex mechanical drawings, and putting forward some reasonable improvement suggestions related to the principle, device selection and structure of PCB design to help the system design succeed at an early date;

8. The test points and silk screen marks are clear, error free, rarely make low-level errors in PCB design, and generally do not cause revision due to PCB design errors. More than 9)% of PCB processing factory projects can always be solved by feedback;

9. Have more knowledge of manufacturability and practice with days. More than 70% of the boards designed can be used for direct mass production.

job content:

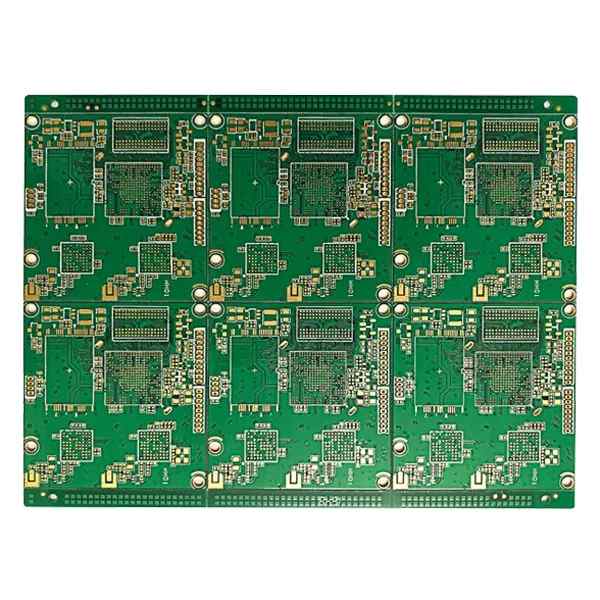

1. Design and modification of extremely complex PCB (such as 8-way DVR backplane, PC motherboard, etc.);

2. Debugging related to self-designed PCB and SI simulation of designated parts;

3. Provide work instructions and wiring rules for all lower level PCB engineers;

4. Write relevant development and debugging logs;

5. Production and maintenance of internal PCB standard packaging library and standard wiring module;

6. If necessary, he also works as a PCB engineer of any lower level.

operating duty:

1. Responsible for the design part of PCB;

2. Responsible for the in-house PCB standard packaging library and the self-designed part of the standard PCB wiring module;

3. Be responsible for their own SI simulation results and solutions.

Position: Senior PCB Engineer

Capability requirements:

1. Master the document conversion between various common PCB design software, and the transferred documents can be basically used for modification;

2. Be familiar with all requirements in high-speed and analog PCB design, and more than 80% of the boards designed or instructed others to design have no relevant problems;

3. Have rich knowledge of manufacturability and use it for practice and guidance. More than 90% of the boards designed or directed by others can be used for direct mass production;

4. Proficient in the layout and wiring of high-density PCB under the control of high-speed rules, and the modules or boards laid can be stable and reliable at the same time to achieve more than 80% of the very aesthetic;

5. Very innovative, and can often put forward various constructive proposals to improve PCB design efficiency, PCB design quality, PCB structure distribution in the system, etc.

job content:

1. Participate in the analysis, planning and simulation of PCB related parts in system design;

2. Organize and conduct PCB design training;

3. Provide work instructions and wiring rules for all lower level PCB engineers;

4. Determine relevant development and debugging logs;

5. SI simulation model search, establishment and specification;

6. The whole board and system SI, PI, EMC simulation, PCB manufacturability performance evaluation, analysis of the causes of problematic PCBs and propose effective solutions;