Speed and throughput of next generation PCB printers

With the simplest description, faster PCB printers logically mean higher throughput However, the overall speed depends on many factors, including the cycle time of each step in the printing cycle (for example: mold wiping frequency, substrate separation speed, and printing speed) The overall throughput speed of the sample printer, that is, the printing speed of each plate must match the production line capacity In other words, if the production line speed is determined by the reflow furnace at the end of the production line, and the fixed time/temperature curve is significantly slower, then the fast printing machine and/or the high-speed chip mounter will not bring any benefits The configuration and balance of the production line should be optimized from the whole production line Therefore, the high-speed mass production of PCB printers is only an important part of achieving maximum benefits

Benefits of higher throughput

From the material handling system (buffer, cardboard loader, etc.) to the operation of various process equipment, the configuration and balance of the production line is an important part of each process of the production line to achieve maximum benefits. Theoretically, printing presses with high throughput are "fast"; Mechanical systems, software, rack stability, motion control, and sequencing all have an impact on each device. By fully understanding the delivery capacity of the printing machine, the production engineer can use the advantages of each equipment with maximum flexibility in any number of production line settings, configurations or scenes. One printing machine has enough conveying capacity to cope with two production lines, so as to make full use of and save equipment investment. If you buy two printers for two production lines, neither of them will be fully utilized.

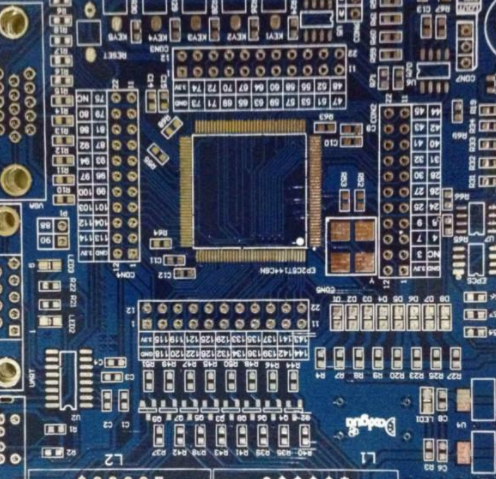

Circuit board

When we talk about "speed", what we really want to talk about is "throughput", that is, the time required for PCB to enter the printer, print, and then exit the printer This is different from the "loop back" time The total throughput is the sum of the cycle time of the process, including printing strokes, stencil wiping, PCB sorting, and aligning pipes Some cycle times can be shortened; Some people cannot, for example, print strokes, it will have an optimal speed (usually not exceeding) depending on the type of solver paste used, template, size of template opening, etc Higher throughput supports mass production and processes

With higher speeds, you can now:

Printing speed is slow;

In order to obtain the best printing resolution, please use a lower template separation speed;

Use MPM Edison efficient wiper to wipe more frequently (if necessary);

After wiping, accurate printing is doubled.

There is time to optimize the settings to provide the maximum possible return!

What is Fast News?

The speed and throughput of the next generation printing press. The mechanical system, software, frame stability, motion control and sequencing of the printing press will affect the overall running speed of a single device. The "total throughput" time is the time from the PCB being guided into the device to exiting the device, which is the real measurement speed. For example, a device with a total throughput time of 15 seconds will be considered a fast device. The total conveying volume time is the sum of the equipment holding time and the time of each process of printing substrate, that is, the accumulation of the cycle time of each process, such as alignment, printing stroke, mold bottom wiping and substrate guiding.

It can only speed up the printing stroke, that is, the moving speed of the scraper on the template, rather than an option. According to different applications, such as fine or standard spacing, size and shape of openings, thixotropy of solder paste, each application will have an "ideal" printing speed to achieve the highest output while eliminating solder paste. Defects are transferred to PCB. A good printing effect is that the solder paste rolls to the front of the scraper under a certain pressure and completely fills the mold opening. If the printing stroke is too fast, the opening will not be filled enough, and the viscosity of solder paste will collapse through shearing. Recall that the ideal printing stroke speed requires printing strokes that last for several seconds. In other aspects, you must consider shortening the entire printing cycle time.

Period Time

PCB printing involves multiple processes, but not every process is a part of every PCB printing process. For example, a sample wiping process with an automatic wiping system is shown below. The manufacturing technical engineer can choose to set the wiper to wipe once every ten substrates or once every three substrates. This depends on many factors, but ultimately on the solder paste spilling around the opening at the bottom of the template. Obviously, the process engineer wants to reduce the frequency of wiping as much as possible, because wiping will also take up the conveying time and the cost of solder paste loss. Changes in the printing process, such as solder paste type, viscosity, mold opening size, substrate morphology and sealing, will affect the wiping frequency. If necessary, there is a specific wiping cycle interval depending on the type of wiping system used. This cycle time must be added to PCB alignment, substrate operation, solder paste replenishment, printing strokes, etc. to establish or calculate "real" throughput or speed. For example, the newly released MPM Edison printer platform has achieved an average throughput speed of 15 seconds for each printed substrate, including printing strokes and mold wiping; The average printing time is further shortened due to the lower mold wiping frequency requirements.

15 second throughput calculation

Of course, each application program will have a different throughput speed, which depends on many factors, including (especially) the type of solver paste used, PCB size, template opening size, and other variables Therefore, the time required for the new MPM Edison printer to reach 15 seconds depends on whether it uses a standard board or a common board and the printing process. This will be the benchmark PCB printing solution for most people The delivery volume of 15 seconds is achieved under the following parameters, including printing stroke and wiping stroke

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.