Manufacturing of double-sided flexible circuit board: covering film processing technology

One of the unique processes in FPC manufacturing is the overlay process There are three treatment methods for the covering layer: covering film, covering layer screen printing, and light coating Not long ago, a new technology expanded the range of choices

The treatment of FPC covering film is divided into three parts:

1. FPC overlay screen printing

2. FPC protective film

3. FPC light coating

1. FPC overlay screen printing

The mechanical efficiency of the missing coating is worse than that of the laminated coating, but the material cost and processing cost are lower. The most commonly used are flexible printed boards that do not require repeated bending on civil products and automobiles. The process and equipment used are basically the same as those for solder mask printing on rigid printed boards, but the ink information used is completely different. It is necessary to select the ink suitable for flexible printed boards. UV curable and heat curable inks are available on the market. The former has short curing time and convenient use, but its general mechanical efficiency and chemical resistance are poor. It is sometimes inappropriate if it is used under bending or harsh chemical conditions. In particular, electroless gold plating must be avoided, as the plating solution will penetrate the covering layer from the end of the window, which will lead to stripping of the covering layer. Since the curing of thermosetting ink takes 20-30 minutes, the drying channel for continuous curing is relatively long, and the intermittent oven is usually used.

2. FPC protective film

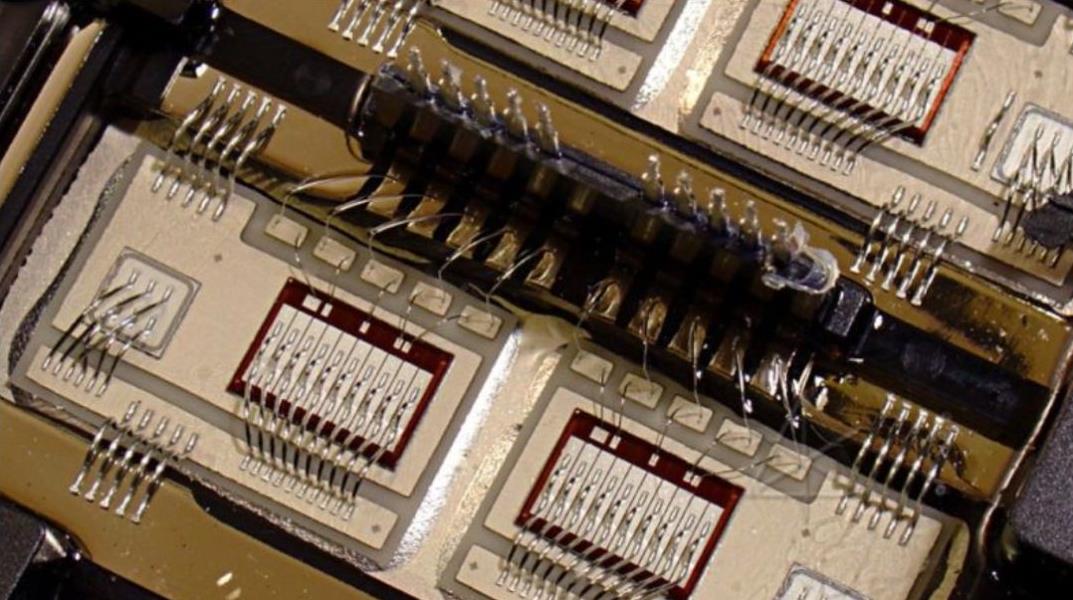

Circuit board

The covering film is the earliest and most commonly used technology for covering flexible printed boards. The same film as the base film of the CCL is coated with the same adhesive as the CCL, making it a semi curing adhesive film, which is sold and supplied by the CCL manufacturer. At the time of delivery, the release film (or paper) is attached to the adhesive film. The semi curing epoxy resin adhesive will gradually cure at room temperature, and should be refrigerated at low temperature. The printed circuit manufacturer shall keep it in a refrigerated warehouse at about 5 ° C before use, or send it by the manufacturer before use. If it can be used for 6 months under refrigeration conditions, the manufacturer of general information guarantees that the service life is 3 to 4 months. Acrylic adhesives hardly cure at room temperature. Even if it is not stored under refrigerated conditions, it can still be used after being stored for more than half a year. Of course, the laminating temperature of this adhesive must be very high.

One of the most important problems in covering film treatment is the mobility management of adhesives. Before the lamination leaves the factory, the information manufacturer will adjust the fluidity of the adhesive to a specific range. Under the condition of refrigeration at appropriate temperature, the service life can be guaranteed for 3 to 4 months, but within the validity period, the fluidity of the adhesive is not fixed, but gradually decreases with the passage of time. Generally speaking, since the adhesive is very flowing when the covering film leaves the factory, during the lamination process, the adhesive is easy to flow out and pollute the terminal part and the connecting plate. At the end of the service life of the adhesive, its fluidity is very small, or even no fluidity. If the lamination temperature and pressure are not high, a covering film with pattern gaps and high adhesive strength cannot be obtained.

The cover film needs to be treated by opening the window, but it cannot be treated immediately after being taken out of the freezer. Especially when the ambient temperature is high and the temperature difference is large, water droplets will condense on the surface. It will absorb water and affect the subsequent process. In this case, the general roll film is sealed in a polyethylene plastic bag. The sealed bag shall not be opened immediately after being taken out of the freezer, but shall be placed in the bag for several hours. When the temperature reaches room temperature, it can be taken out of the sealed bag. Take out the cover film for treatment

The laminating method has a great influence on the state of the adhesive filled between circuits and the bending performance of the finished flexible printed board. Laminated materials are commercially available general purpose products. Considering the cost of mass production, each flexible board factory has its own laminated materials. According to the FPC structure and the data used, the data and structure of the laminate are also different.

3. FPC light coating

The basic process of the light coating is the same as that of the photoresist film used for rigid printed boards. The materials used also include dry film type and liquid ink type. In fact, solder mask dry film is still different from liquid ink. Although the coating process of dry film type and liquid type is completely different, the same device can be used for exposure and subsequent process. Of course, the specific process conditions will be different. Dry film must be pasted first, and all circuit diagrams shall be covered with dry film. The common dry film method may have bubbles between production lines, so vacuum coating machine is used.

The ink type is to apply the ink on the circuit pattern by screen printing or spraying Screen printing uses more coating methods, the same process as rigid printed boards However, the thickness of the leak printing ink is relatively thin, basically 10-15um, due to the square shape of the circuit Direction: The ink thickness of one printing is uneven, and even skip printing To improve reliability, change the missing printing direction and then perform a second missing printing Spraying method is still a relatively new technology for PCB The spraying thickness can be adjusted through the nozzle, and the adjustment range is wide. The coating is even. There are few parts that cannot be coated, and the coating can be continuous Suitable for mass production