Prevent reflow in PCB production

So how to prevent the PCB from going through the reflow furnace from bonding and plate warming, the following is a detailed explanation for everyone:

1. Reduce the impact of temperature on PCB

Since "temperature" is the main source of PCB stress, as long as the temperature of the reflow furnace decreases or the heating and cooling speed of the reflow furnace decreases, the bending and warping of PCB can be greatly reduced Occurs However, other side effects, such as short circuits, may occur

2 PCB has high Tg board

Tg is the glass transition temperature, that is, the temperature at which the data changes from glass state to rubber state The lower the Tg value of the data, the faster the PCB starts to soft after entering the reflow furniture, and the longer it will become soft rubber, and the PCB will of course be more serial The use of higher Tg boards can improve their ability to withstand stress and deformation, but the price of materials used for production is relatively high

3 New printed circuit board

In order to achieve the purpose of light and thinner for many electronic products, the thickness of PCB has left 1.0mm, 0.8mm, or even 0.6mm This thickness must be kept from deforming after the reflow furnace, which is really difficult for others If there is no requirement for brightness and thinness, it is recommended to use a thickness of 1 6mm printed circuit board, which can greatly reduce the risk of bending and deformation of the board

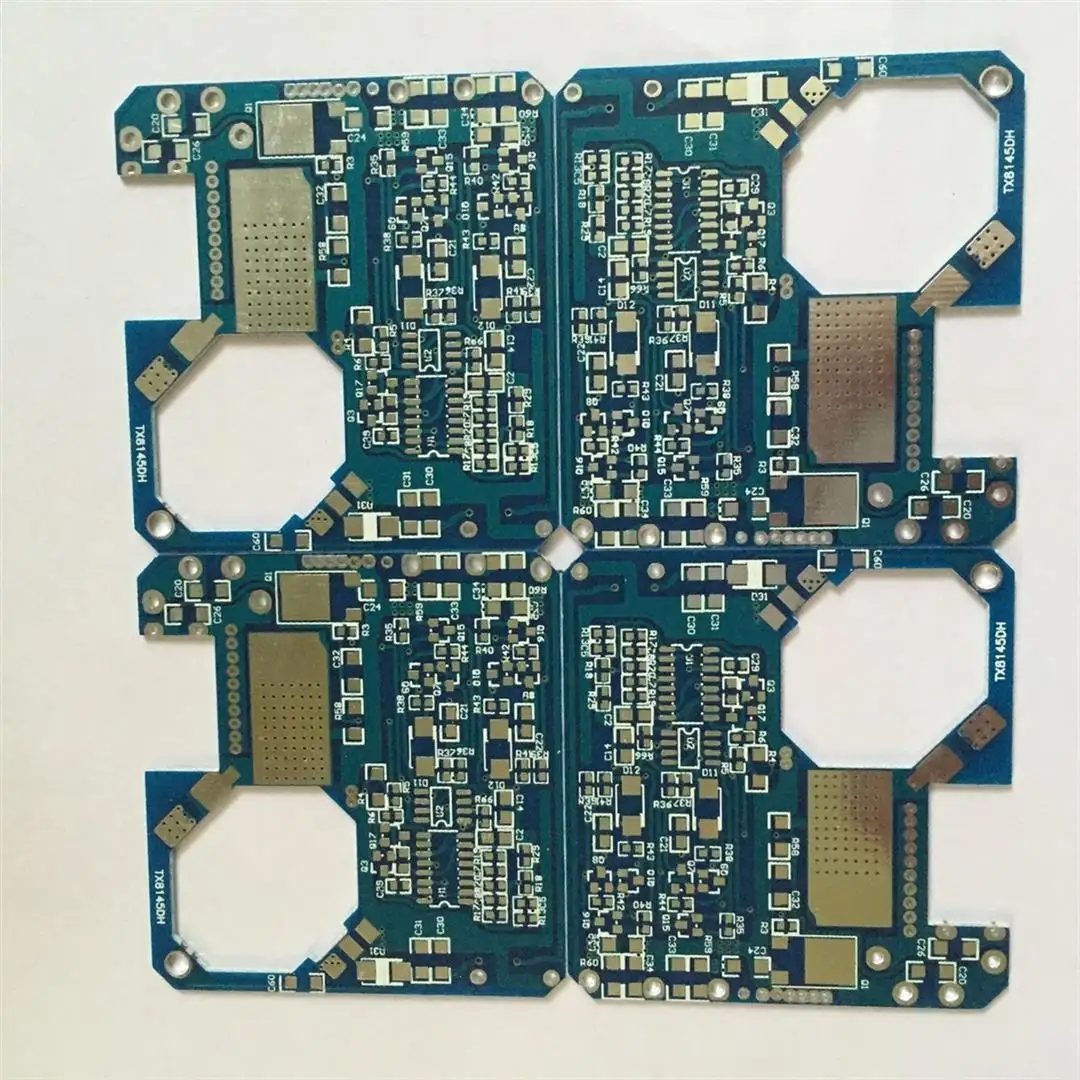

Printed circuit board

4. Reduce the number of puzzles

Since most of the reflow furniture use chains to drive the PCB forward, the larger the PCB design size, the larger the PCB will dent and deform in the reflow furniture due to its own weight, so try to treat the PCB as the edge of the board Placing it on the chain of the reflow furnace can reduce the depression and deformation caused by the weight of the circuit board itself The decrease in the number of switchboards is also due to this reason The minimum sag deformation is reached

5. Used furnace tray fixture

If the above methods are difficult to achieve The furnace tray can reduce the bending and warping of the board, because it is hoped that the tray can fix the printed circuit board regardless of thermal expansion or cold contraction At the temperature of PCB is lower than the Tg value and starts to harden again, the size of the garden can be maintained

If the single-layer tray cannot reduce the PCB, a cover must be added to clamp the PCB with the upper and lower pads This can greatly reduce the PCB board deformation through the reflow furniture However, this tray is expensive and requires manual placement and recycling of trays

6. Use Router instead of V-Cut to use the sub-board

Since V-Cut will destroy the structural length of the panel between the PCB

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

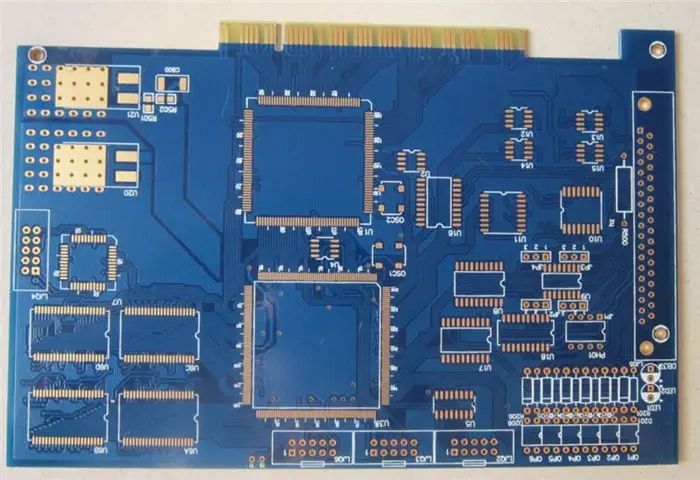

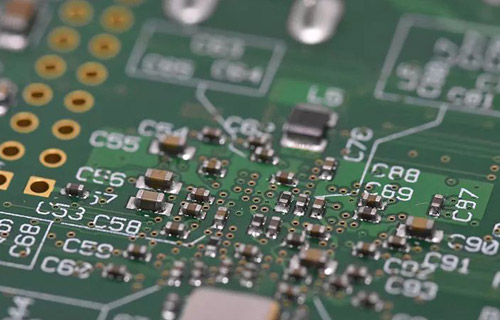

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.