Cause of HDI board blind hole interconnection failure

Cause of Blind Hole Interconnection Failure HDI Board

1 Excessive energy during laser ablation

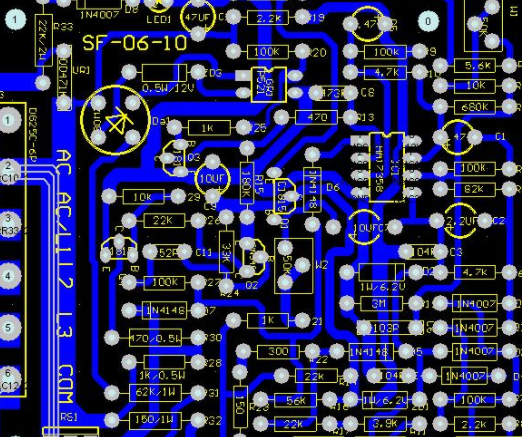

Laser ablation method is currently the main production process for making blind holes. Although CO2 laser cannot directly ablate the copper layer, if the copper layer is specially treated to make its surface have strong infrared wavelength absorption characteristics, it will rapidly raise the copper layer to a very high temperature The inner copper layer at the bottom of the blind hole is usually brown, because the brown copper surface reflects less laser light, and its rough surface structure adds diffuse reflection of light. Through the absorption of new light waves, the brown copper box surface is an organic layered structure, which can also promote light absorption Therefore, if the laser energy is too large after laser drilling, it can recrystallize the inner copper surface layer at the bottom of the blind hole, resulting in changes in the internal copper structure

Printed circuit board

2. Desmear is not clean

Removal of epoxy drilling or flag removal is an extremely important process before blind hole electroplating Because the thin resin layer may make the blind hole in the transistor state During the E-TEST test, due to the contact pin pressure, it may pass the test. After assembly, it may have problems such as open circuit or contact failure However, for example, there are about 70 to 100 mobile phone boards, and each board has 000 blind holes. When removing glue, errors will inevitably occur occasionally

With the continuous improvement of various manufacturers' cavitation agent systems, only by closely monitoring the plating solution and immediately replacing the plating solution before any problems occur, can the proper output be ensured

3. The quality of the copper plating layer on the surface of the inner connecting plate is abnormal

The abnormal quality of the copper plated layer on the surface of the inner connecting pad is also a reason for the blind hole ICD It plays an important role. The physical properties of the copper coating depend on the structure and chemical composition of the copper coating The figure shows the ICD caused by rough electroplating on the inner surface of the bottom of the blind hole The copper surface of the inner layer is easy to lead to the unclean removal of glue. The third problem is the crystallization of the copper surface itself, and it is easy to electroplating blind holes Defects such as poor bonding between the electroless copper plating and the inner copper occur. In addition, once the ICD is pulled by great pressure, it is easy to send the ICD

4. The difference in material expansion and contract is too large

The problem of material matching also has an important impact on the connection reliability of blind vias Figure 8 and Figure 9 are photos of electroplating blind holes of secondary composite plate filled with ICD It can be seen that RCC data is used for secondary composite plate L1-L2 and LDP data is used for L2-L3 plating blind hole filling layer Due to the high temperature and high heat of lead-free welding, the three kinds of data with large difference in thermal expansion coefficient of electroplating blind holes show that LDP and RCC have different degrees of expansion and contraction, which makes the proportion of blind hole ICD in LDP layer increase significantly Therefore, when making multilayer boards, attention should be paid to the selection and matching of data

5. Halogen-free RCC will increase the probability of blind hole ICD

The halogen free RCC material is a new type of material developed in accordance with the requirements of the RoHS directive It contains no halogen prohibited by RoHS and has excellent flame retardancy The main blocking mechanism is the use of phosphorus and nitrogen to replace halogen, which reduces the polarity of the polymer chain and increases the molecular weight of the resin At the same time, adding aluminum oxide and other fillers will also increase the polarity of information The halogen-free data show some characteristics different from traditional epoxy resin Therefore, some problems may occur when the halogen-free data are matched with the original plating solution, which may lead to thin coating

6. Excessive manual welding temperature or rework

During the assembly process of HDI plate, parts need to be manually welded at certain positions Manual welding temperature, the proficiency of welding personnel during operation, and the number of rework have a great impact on the welding quality

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.