How to select PCB boardcorrectly

With the rapid development of digital systems, transmission line loss, previously considered negligible, is now becoming the primary concern of PCB design. When the clock frequency is higher than 1GHz, the impact of frequency dependent transmission loss has actually occurred, especially in the high-speed SerDes interface. The signal has a very fast rise time. Digital signals can carry higher frequency energy than their own repetition frequency. These higher frequency energy components are used to construct ideal fast conversion digital signals. Today's high-speed serial bus often has a large amount of energy concentration on the 5th harmonic of the clock rate. There are many high-speed digital applications with speeds of 10 Gbit/s or higher. These applications use 5 GHz fundamental frequency and 15 GHz, 25 GHz and other harmonics. In this frequency range, most common PCB materials have very significant differences in dielectric loss (Df), which leads to serious signal integrity problems. This is one of the reasons why high-speed digital PCBs use special boards designed for high-frequency applications.

These materials are formulated with low loss factors and minimal variation over a wide frequency range. These plates were used in high frequency RF applications in the past and are now used in 77 GHz and higher applications. In addition to the improvement of dielectric loss factors, these plates are also equipped with strict thickness control and Dk control, which is more conducive to ensuring signal integrity. AMD released the third generation of Ryzen Reyron processor at the 2019 Taipei Computer Show. In addition to its 7nm CPU, AMD's supporting X570 chipset also introduced support for PCIe 4.0. SSD using PCIe 4.0 NVMe also began to be introduced to the market. It is expected that the PCIe 5.0 specification will also be released two years later.

The data rate of PCIe 5.0 will reach 32GT/s, which will increase the insertion loss related to frequency. The selected PCB material will have a huge impact on the insertion loss of each area. If the influence of the board on the high-speed signal is not considered when designing the PCB, the old driver will also roll over! When selecting PCB boards, a balance must be achieved between meeting PCB design requirements, mass production and cost. In short, the design requirements include electrical and structural reliability. Usually, the board problem is more important when designing very high-speed PCB boards (frequencies greater than GHz).

For example, the commonly used FR-4 material has a large dielectric loss Df (Dielectric loss) at several GHz frequencies, which may not be applicable. The operation speed of high-speed digital circuit is the main factor for PCB selection. The higher the circuit speed is, the smaller the Df value of the selected PCB should be. Circuit boards with medium and low loss will be suitable for 10Gb/S digital circuits; The plate with lower loss is suitable for 25Gb/s digital circuit; The board with ultra-low loss will adapt to faster high-speed digital circuits, whose speed can be 50Gb/s or higher.

How to design vias in PCB wiring

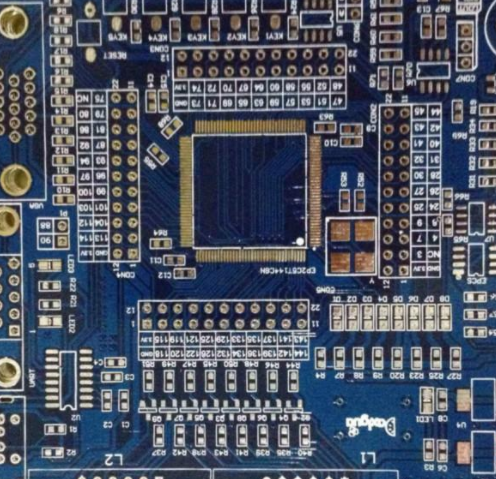

PCB company is a PCB wiring design company with a team of PCB design engineers with average design experience of more than 10 years, which can provide multi-layer, high-frequency and high-speed PCB wiring design services. Next, we will introduce how to design vias in PCB wiring? What is via? via is one of the important components of multilayer PCB, and the cost of drilling usually accounts for 30% to 40% of the cost of PCB manufacturing. In short, each hole on a PCB can be called a via.

From the perspective of function, vias can be divided into two categories: one is used as electrical connection between layers; Second, it is used for fixing or positioning devices. In terms of process, vias are generally divided into three categories, namely blind holes, buried holes and through holes. The blind hole is located on the top and bottom surfaces of the printed circuit board, and has a certain depth. It is used to connect the surface line and the lower inner line. The depth of the hole usually does not exceed a certain ratio (aperture). Embedded hole refers to the connection hole located in the inner layer of the printed circuit board, which will not extend to the surface of the printed circuit board. The above two types of holes are located in the inner layer of the circuit board. Before lamination, the through hole forming process is used to complete the hole. During the hole forming process, several inner layers may be overlapped. The third is called through hole, which passes through the whole circuit board and can be used for internal interconnection or as the installation and positioning hole of components. Because the through-hole is easier to realize in technology and lower in cost, it is used in most printed circuit boards instead of the other two kinds of through-hole.

The following vias, unless otherwise specified, are considered as through-hole. From the design point of view, a via is mainly composed of two parts: one is the drill hole in the middle, and the other is the pad area around the drill hole. The size of these two parts determines the size of the vias. Obviously, when designing high-speed and high-density PCBs, designers always hope that the smaller the vias are, the better, so that more wiring space can be left on the board. In addition, the smaller the vias are, the smaller their parasitic capacitance is, which is more suitable for high-speed circuits. However, the reduction of hole size also brings about an increase in cost, and the size of vias cannot be reduced without limitation. It is limited by drilling and electroplating technology: the smaller the hole, the longer the drilling time will take, and the easier it is to deviate from the center; And when the depth of the hole exceeds 6 times of the drilling diameter, it is impossible to ensure that the hole wall can be uniformly copper plated. For example, the thickness (through-hole depth) of a normal 6-layer PCB is about 50Mil, so the minimum drilling diameter that PCB manufacturers can provide can only reach 8Mil. Parasitic characteristics of via