What are the common circuit protection elements in PCBA processing?

The circuit board manufacturer will explain to you which circuit protection components are commonly used in PCBA processing

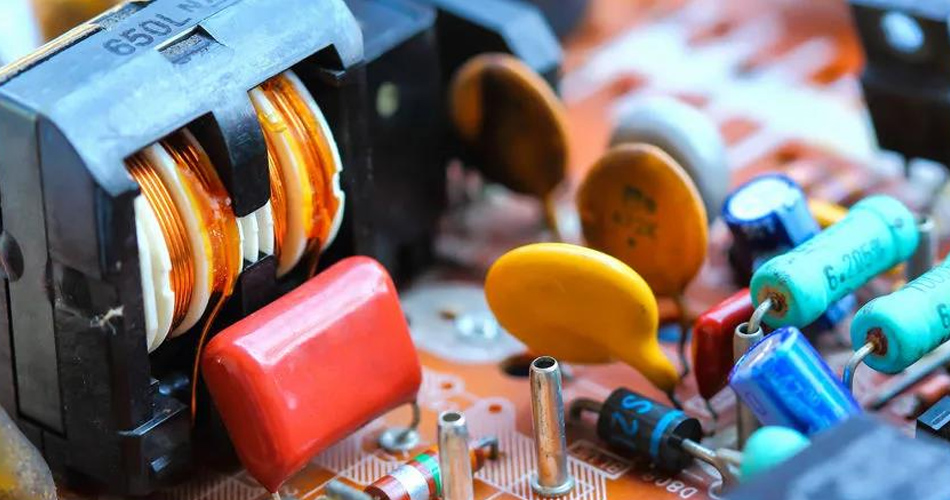

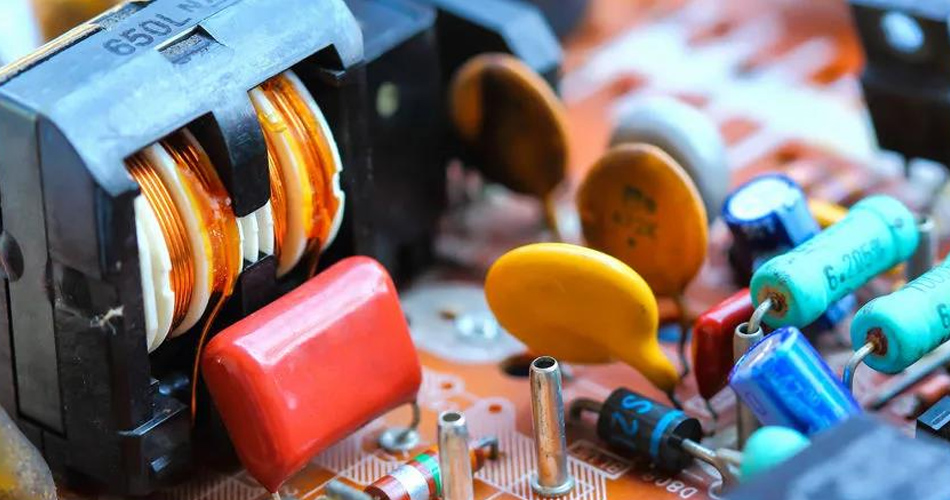

Electronic circuits are easy to be damaged when overvoltage, overcurrent, surge and other conditions occur. With the development of technology, electronic circuit products are increasingly diversified and complex, and circuit protection becomes particularly important. The circuit protection elements have also changed from simple glass tube fuses to more types and superior protection performance.

What is the significance of circuit protection?

In all kinds of electronic products, the setting of over-voltage protection and over-current protection is becoming more and more important. What is the significance of circuit protection? Let's talk about it today:

(1) As the integration of circuit boards is getting higher and higher, the price of boards is also rising with the tide, so we need to strengthen protection.

(2) The working voltage of semiconductor devices and ICs tends to be lower and lower, and the purpose of circuit protection is to reduce energy loss, reduce heat generation and prolong service life.

(3) On board equipment, because the operating environment is worse than that of ordinary electronic products, the driving conditions of the car change constantly, and the car generates a large instantaneous peak voltage when starting. Therefore, overvoltage protection components are generally used in the power adapter of these electronic equipment supporting products.

(4) Communication equipment and communication places have certain requirements for lightning surge protection. It is important to use overvoltage protection and overcurrent protection components in these equipment. They are the key to ensure users' personal safety and normal communication.

(5) Most of the failures of electronic products are caused by overvoltage or circuit phenomena in electronic equipment circuits. As our requirements for the quality of electronic equipment become higher and higher, the protection of electronic circuits becomes more and more important.

So circuit protection is so important, what are the common circuit protection components? Today I will introduce some of them to you.

1、 Lightning protection device

1. Ceramic gas discharge tube:

The ceramic gas discharge tube is the most widely used lightning protection device. The reason why the ceramic gas discharge tube is the most widely used lightning protection device is that the ceramic gas discharge tube can play a very good role in the protection of both DC power supply lightning protection and various signal lightning protection. Its greatest characteristics are large flow, small interstage capacitance, high insulation resistance, and wide selection range of breakdown voltage.

2. Semiconductor discharge tube:

Semiconductor discharge tube is a kind of over-voltage protection device, which is made by using the principle of thyristor. The device conduction discharge is triggered by the breakdown current of PN junction, and it can flow large surge current or pulse current. The range of breakdown voltage constitutes the range of overvoltage protection.

The solid discharge tube can be directly bridged at both ends of the protected circuit when used. It is characterized by accurate conduction, fast response (response time of ns level), strong surge absorption capacity, bidirectional symmetry, and high reliability.

3. Glass discharge tube:

Glass discharge tube (powerful discharge tube, lightning protection tube) is a new lightning protection device introduced at the end of the 20th century. It combines the advantages of ceramic gas discharge tube and semiconductor overvoltage protector: high insulation resistance (≥ 10 ^ 8 Ω), small interelectrode capacitance (≤ 0.8pF), large discharge current (up to 3 kA at most), bidirectional symmetry, fast reaction speed (no hysteresis phenomenon of impact breakdown), stable and reliable performance, and low voltage after conduction, In addition, it has the advantages of high DC breakdown voltage (up to 5000V), small size, long service life, etc. Its disadvantage is that the DC breakdown voltage has a large dispersion (± 20%).

2、 Overvoltage device

1. Varistor:

Varistors are also the most used voltage limiting devices. Using the nonlinear characteristics of the varistor, when the overvoltage appears between the two poles of the varistor, the varistor can clamp the voltage to a relatively fixed voltage value, thus realizing the protection of the subsequent circuit.

The response time of the varistor is ns, which is faster than that of the air discharge tube and slightly slower than that of the TVS tube. Generally, the response speed of the varistor used for overvoltage protection of electronic circuits can meet the requirements. The junction capacitance of varistors is generally in the order of hundreds to thousands of pF. In many cases, it is not suitable for direct application in the protection of high-frequency signal lines. When it is used in the protection of AC circuits, because its junction capacitance will increase leakage current, it needs to be fully considered in the design of protective circuits. The flow capacity of varistor is larger, but smaller than that of gas discharge tube.

2. Chip varistor:

SMD varistor is mainly used to protect components and circuits from ESD generated in power supply, control and signal lines.

3. Transient suppression diode:

Transient suppressor TVS diode is widely used in the protection of semiconductor and sensitive devices, usually for secondary protection. Basically, they are used for secondary protection after ceramic gas discharge tubes, and some users directly use them for primary protection of products.

It is characterized by fast reaction speed (ps level), small size, large pulse power, low clamping voltage, etc. 10/1000 μ The s-wave pulse power ranges from 400W to 30KW, and the peak pulse current ranges from 0.52A to 544A; The breakdown voltage has a series value from 6.8V to 550V, which is convenient for various circuits with different voltages.

3、 Overcurrent device

Self recovery fuse:

Self recovery fuse PPTC is a kind of over-current electronic protection element, which is made of high molecular organic polymer under the conditions of high pressure, high temperature and vulcanization reaction, mixed with conductive particle materials, and processed by special process. Self recovery fuse (PPTC: polymer self recovery fuse) is a positive temperature coefficient polymer thermistor used for over-current protection and can replace current fuse.

When the circuit works normally, its resistance value is very small (the voltage drop is very small). When the circuit has over-current and its temperature rises, the resistance value increases sharply by several orders of magnitude, reducing the current in the circuit to below the safe value, so that the following circuit can be protected. After the over-current disappears, it will automatically return to the low resistance value.

4、 Electrostatic element

1. ESD static discharge diode:

ESD ESD diode is an overvoltage and anti-static protective element, which is designed for I/O port protection of high-speed data transmission applications. ESD electrostatic diode is used to prevent sensitive circuits in electronic equipment from being affected by ESD (electrostatic discharge).

It can provide very low capacitance, and has excellent transmission line pulse (TLP) test, as well as IEC6100-4-2 test capability, especially after the number of multiple samples reaches 1000, so as to improve the protection of sensitive electronic components.

2. Inductance:

It is believed that we all know the relationship between electromagnetism. The role of inductance is that when the circuit is just started and everything is not stable, if there is current in the inductance, it will certainly produce an induced current in the opposite direction of the current (Faraday's electromagnetic induction law). After the circuit has been running for a period of time, everything is stable, the current has not changed, and the electromagnetic induction will not produce current. At this time, it will be stable, There will be no sudden changes, thus ensuring the safety of the circuit. Like a waterwheel, it turns slowly due to resistance at first, and then slowly becomes peaceful.

3. Magnetic bead:

The magnetic bead has a high resistivity and permeability, which is equivalent to the resistance and inductance in series, but the resistance and inductance vary with the frequency. It has better high-frequency filtering characteristics than ordinary inductors. It is resistive at high frequencies, so it can maintain high impedance in a relatively wide frequency range to improve the FM filtering effect. It has been used on Ethernet chips.