BGA is the abbreviation of the English Ball Grid Array Package, that is, the ball grid array package.

With the progress of technology in the 1990s, chip integration continued to improve, the number of I/O pins increased sharply, power consumption also increased, and the requirements for integrated circuit packaging were more stringent. In order to meet the needs of development, BGA packaging began to be used in production.

The memory encapsulated by BGA technology can increase the memory capacity by two to three times without changing the volume of the memory. Compared with TSOP, BGA has a smaller volume, better heat dissipation performance and electrical performance. BGA packaging technology has greatly improved the storage capacity per square inch, using BGA packaging technology memory products under the same capacity, the volume is only one-third of TSOP packaging; In addition, compared with the traditional TSOP package, the BGA package has a more rapid and effective heat dissipation way.

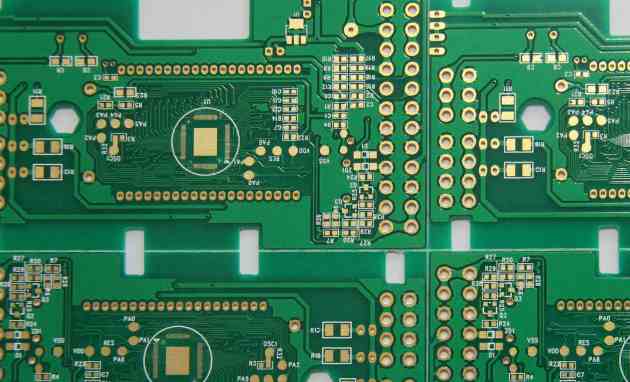

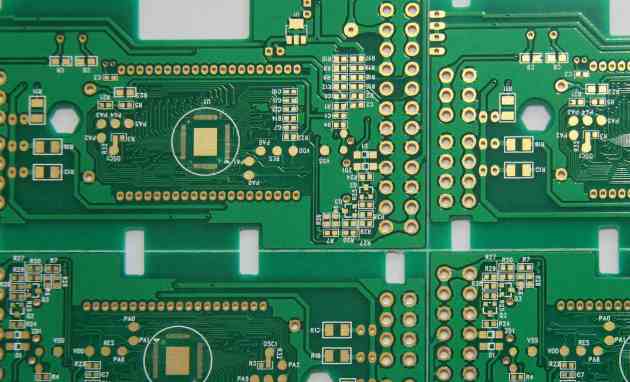

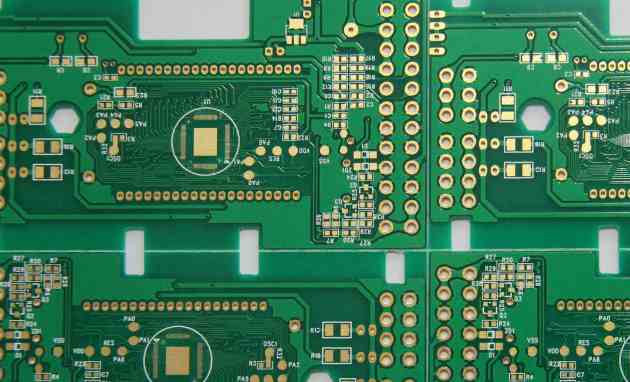

The I/O terminals of BGA package are distributed under the package in the form of circular or cylindrical solder joints in the form of array. The advantage of BGA technology is that although the number of I/O pins increases, the spacing of pins increases rather than decreases, thus improving the assembly yield. Although its power consumption increases, BGA can be welded by controlled collapse chip method, which can improve its electric heating performance. The thickness and weight are reduced compared with previous packaging technologies; The parasitic parameter is reduced, the signal transmission delay is small, and the use frequency is greatly increased. Assembly can be coplanar welding, high reliability.

When it comes to BGA packaging, it is necessary to mention Kingmax's patented TinyBGA technology, TinyBGA English full name Tiny Ball GridArray (small ball grid array package), which is a branch of BGA packaging technology. Kingmax was successfully developed in August 1998, the ratio of the chip area to the package area is not less than 1:1.14, which can increase the memory capacity by 2 to 3 times under the same internal volume, compared with TSOP package products, it has a smaller volume, better heat dissipation performance and electrical performance.

Memory products using TinyBGA packaging technology have only 1/3 of the volume of TSOP packaging under the same capacity. The pins of TSOP encapsulated memory are led from around the chip, while TinyBGA is led from the center of the chip. This method effectively reduces the transmission distance of the signal, and the length of the signal transmission line is only 1/4 of the traditional TSOP technology, so the attenuation of the signal is also reduced. This not only greatly improves the anti-interference and anti-noise performance of the chip, but also improves the electrical performance.

Using TinyBGA package chip can resist up to 300MHz external frequency, while using traditional TSOP package technology can only resist up to 150MHz external frequency.

The Tiny BGA package also has a thinner memory thickness (less than 0.8mm package height), and the effective heat dissipation path from the metal substrate to the heat sink is only 0.36mm. Therefore, TinyBGA memory has a higher heat transfer efficiency, which is very suitable for long running systems and excellent stability.

How can LED effectively reduce the thermal resistance of thermal conductive silicone sheet

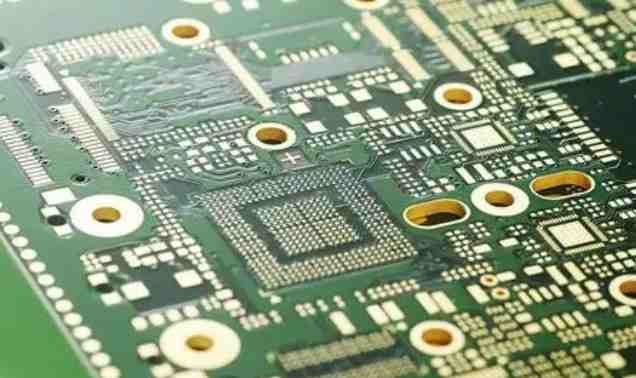

Aluminum based copper clad plate is a metal circuit board material, composed of copper foil, thermal insulation layer and metal substrate, its structure is divided into three layers: line layer: equivalent to ordinary PCB copper clad plate, line copper foil thickness loz to 10oz. Insulation layer: Insulation layer is a layer of low thermal resistance thermal insulation material. Base: is a metal substrate, generally aluminum or optionally copper. Aluminum based copper clad plate and traditional epoxy glass cloth laminate and so on.

The heat dissipation problem of LED is the most headache problem of LED manufacturers, but aluminum substrate can be used, because aluminum has a high thermal conductivity and good heat dissipation, which can effectively export the internal heat. Aluminum substrate is a kind of unique metal base copper clad plate, which has good thermal conductivity, electrical insulation and mechanical processing properties. In the design, the PCB should also be as close to the aluminum base as possible, and the contact is close, so as to reduce the thermal resistance generated by the thermal conductive silicone sheet part of the thermal conductive material.

The characteristics of aluminum substrate: surface mounting technology; Replace fragile ceramic substrate for better mechanical durability; The thermal diffusion is treated very effectively in the circuit design. Reduce the operating temperature of the product, improve the power density and reliability of the product, extend the service life of the product; Reduce product volume, reduce hardware and assembly costs; The circuit layer is usually etched to form a printed circuit, so that each part of the component is connected to each other, under normal circumstances, the circuit layer requires a large current carrying capacity, so that thicker copper foil should be used, the thickness is generally 35μm~280μm; The thermal insulation layer is the core technology of the aluminum substrate, which is generally composed of special polymers filled with special ceramics, small thermal resistance, excellent viscoelastic properties, thermal aging resistance, and ability to withstand mechanical and thermal stress.

The thermal insulation layer of high performance aluminum substrate uses this technology, so that it has excellent thermal conductivity and high strength electrical insulation performance; The metal base is the supporting component of the aluminum substrate, which requires high thermal conductivity, generally aluminum plate, and copper plate can also be used, which is suitable for conventional mechanical processing such as drilling, punching and cutting. PCB materials have incomparable advantages compared with other materials. Suitable for power component surface mount SMT public art. Without heat sink, the volume is greatly reduced, the heat dissipation effect is excellent, good insulation and mechanical properties.