The degree of automation of electronic equipment is a sign of whether a country is a power in electronic manufacturing. Domestic electronic machine SMT(surface mount technology) manufacturing equipment in printing presses, reflow welding, AOI(automatic optical inspection) equipment and other links have made great progress, and in the SMT production line of the most critical placement machine (except for small placement machine) equipment is still not a company can produce, facing severe capital, technology, standards and many other problems. To realize the dream of electronic manufacturing power, we must take the road of independent research and development of SMT equipment, and concentrate our superior strength to break through the industrialization dilemma of the SMT machine.

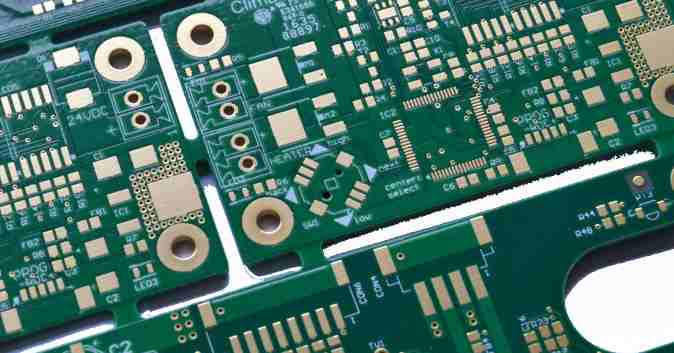

SMT(Surface Mount)

Technology refers to a technology in which chip components are mounted and welded on the surface of the printed circuit board. Compared with the traditional through hole assembly technology, the technology has the advantages of high assembly density, small product size (volume reduction by 40% to 60%), light weight (weight reduction by 60% to 80%), high reliability, strong vibration resistance, and easy automation.

At present, more than 80% of the electronic products in developed countries such as Japan and the United States use SMT. Among them, network communications, computers and consumer electronics are the main application areas, accounting for about 35%, 28%, 28% respectively, and other application areas include automotive electronics, medical electronics and so on.

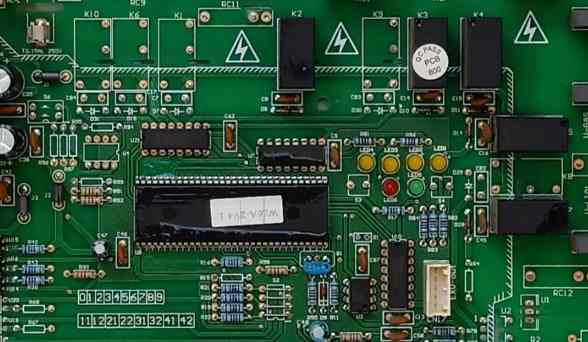

The SMT production line mainly includes the following equipment: SMT machine, printing machine, SPI(solder paste detector), wave soldering equipment, reflow welding equipment, AOI testing equipment, X-Ray testing equipment, repair workstation, etc. The technologies involved finclude:mounting technology, welding technology, semiconductor packaging technology, assembly equipment design technology, circuit forming technology, function design simulation technology, etc.

Among them, the SMT machine is used to achieve high-speed, high-precision, automatic placement of components equipment, related to the efficiency and accuracy of the SMT production line, is the most critical and most complex equipment, usually accounting for more than 60% of the entire SMT production line investment. At present, the placement machine has developed from the early low-speed mechanical placement machine to high-speed optical alignment placement machine, and to multi-functional, flexible, modular development.

Domestic enterprises in printing, welding, testing and other links have emerged more powerful enterprises, such as Nitto, Jingtuo welding equipment, Kegg printing press, Shenzhou Vision AOI testing equipment, X-Ray testing equipment and so on. But the core link of the SMT machine is still controlled by Japan, Germany, South Korea, the United States, the main manufacturers include: ASMPT(ASMPT in 2011 acquired Siemens's SIPLACE mounting equipment department), Panasonic, Global, Fuji, Yamaha, JUKI, Samsung and so on.

Driven by the new technological revolution and new demands for economic and social development, major changes have taken place in both depth and breadth of demand. At present, transformation and upgrading and the integration of the two are symbolic concepts that reflect the changes in demand under the role of these two driving factors. Reducing labor costs and enhancing the level of automation is the fundamental requirement for the technological transformation and upgrading of the manufacturing side, and it also brings a strong demand for SMT equipment.

On the one hand, it puts forward higher requirements for production and manufacturing complexity, accuracy, processes and specifications; On the other hand, the cost of factors such as labor is rising, facing the dual demands of cost and efficiency. The above two reasons have given birth to automated, intelligent and flexible production, processing and assembly, system installation, packaging and testing. At present, Sichuan Changhong has planned to improve the level of automation through technological progress, so as to reduce costs and maintain competitiveness, and strive to reduce labor costs by 20% in the past two years and 50% in four years.

As competition in the electronics industry increases, companies need to meet increasingly short time-to-market for new products, more stringent environmental requirements for cleaning and lead-free solder applications, and adapt to the trend towards lower costs and more miniaturization, which puts higher demands on electronic manufacturing equipment. Electronic equipment is developing in the direction of high precision, high speed, easier to use, more environmentally friendly and more flexible production lines. The high speed head and multi-function head of the SMT machine can be switched arbitrarily; The adhesive head is replaced by the dispensing head, which becomes the dispensing machine. The stability of printing and mounting accuracy will be higher, and the flexibility held by the parts and substrate changes will be stronger.

At the same time, through the production line high-speed, equipment miniaturization brings high efficiency, low power, low cost. For the SMT machine, the demand for high-speed multi-function SMT machines that can meet the double advantages of production efficiency and multi-function is gradually increasing, and the production mode productivity of dual-channel mounting can reach about 100000CPH.

The integration trend of semiconductor packaging and surface mount technology is obvious.

With the increasing miniaturization of electronic products, the diversification of functions and the increasing precision of components, the integration of semiconductor packaging and surface mount technology has become a general trend. At present, semiconductor manufacturers have begun to apply high-speed surface mount technology, and surface mount production lines have also integrated some applications of semiconductors, and the traditional assembly grade boundaries have become increasingly blurred. The integrated development of technology has also brought many products that have been recognized by the market. For example, direct wafer feeders from UnovisSolutions, a subsidiary of Global Instruments, provide a good solution for the integration of surface mount and semiconductor assembly.

In terms of the mounting speed of the placement machine, the SIPLACEX4iS exhibited by ASMPT, which represents the advanced level of the global placement machine, has a mounting speed of 150000CPH, and the actual mounting beat is 0.024 seconds/point.

In the "2013 Assembly Technology Roadmap", the JEITA Electronic Assembly Technology Committee expects that with the explosive growth of consumer demand for low-end electronic products, the requirements of super mass production are expected to make the mounting speed of the SMT machine reach 160000CPH(0.0225 seconds/point) in 2016. 240000CPH(0.015 seconds/point) in 2022. The mounting speed of chip-level packaged devices will increase from 3,600 CPH in 2012 to 3,800 CPH in 2016 and 4,000 CPH in 2022.

At that time, the picking and placing of the mounting head of the mounter will undergo fundamental changes, and the part feeding part will also form a feeding part system without part supply and exchange, and a new generation of high-performance continuity supply method will enter people's vision.

At present, the Chip parts selected for electronic products tend to be miniaturized and thin, and the chip wiring spacing and welding ball diameter have been reduced, which puts forward higher requirements for the alignment and positioning accuracy of mounting equipment.