When choosing flexible PCB reinforcing boards, it is very important to understand their working principle and use method. Flexible PCB stiffeners increase the overall stiffness of the board in units of flexural stiffness (N/mm). This is often referred to as the "E" value. The higher the E value, the stiffer the board.

The number of layers also plays an important role in determining the stiffness of a flexible PCB. To determine how much stiffness you need, you need to know how many layers your design requires. For example: if you have a 2 layer design with 1 ounce copper on each side and 1 ounce copper on both sides, your E value should be around 600N/mm (1 ounce copper). If you want it harder, 4oz copper will give you an E value of 900N/mm (2 oz per layer).

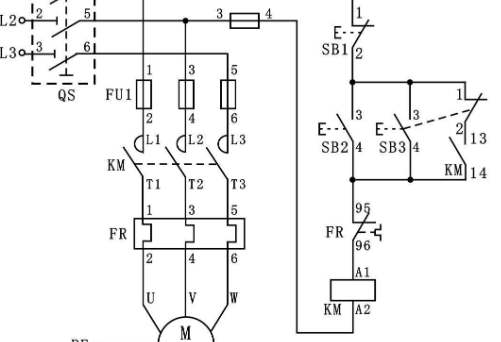

Placement of stiffeners in Flex PCB

Top stiffener

The top layer of flexible pcb stiffeners can be used to provide structural support for the entire flexible pcb board. These stiffeners are often used when a flexible pcb circuit bears a lot of weight on one side, such as when it is connected to a device such as an LED display. Stiffeners help transfer weight evenly to the sides of the flexible pcb board.

Bottom stiffener

When you need extra strength in only one area of a flexible PCB board, the underlying flexible stiffeners are usually used. For example, if you have an active component in an area that requires more support than the rest of the flexible pcb design, you can add stiffeners here for better mechanical support and to prevent fatigue damage from repeated use over time.

Use double or multiple stiffeners in flexible PCBS

Multiple flexible PCB stiffeners are used to provide higher stiffness and strength for flexible PCBS. They are usually placed in key locations on the circuit board and can be made of different materials, including metal and plastic. A key step in designing a multi-stiffener board layout is to determine which areas of a flexible pcb circuit require greater stiffness than others. This can be done by mechanical analysis of each area of interest or by looking at locations in flexible pcb products that are prone to bending.

The main problem with using multiple stiffeners in flexible PCBS is that it is not suitable for all applications. If you have high density perforations, you may need to use multiple stiffeners. To determine if this is necessary, first look at the bending modulus of the material and compare it to the dielectric constant. If both are high (e.g., > 3), you can usually use a single stiffener. If they are low (e.g., < 2), you may need multiple stiffeners to get adequate mechanical support.

In addition to the bending modulus and dielectric constant, other factors affect whether double hardening is required:

Number of through holes per square inch (Vpsi)

This refers to how many electroplated through-holes exist on a given area of a flexible pcb board. The more vpsi there are, the more difficult it is for a single stiffener to support all the stiffeners without over-bending or collapsing at some point during flex pcb assembly due to overloading of side forces (e.g. paste extrusion and take and put action).

Through-hole size

During the design of flexible pcb board layouts, through-holes are usually larger than required to meet more current and power density requirements. This can cause problems when using a single stiffener, because as more current flows through it, it will be stretched beyond its elastic limit. Double stiffeners can help alleviate this problem by providing more support for the big holes and preventing them from buckling under pressure during flexible pcb assembly.

The density of the components on the plate

Components such as chipsets and memory devices can be packed tightly together, increasing the risk of damage during fetch and drop operations. If dual hardening is not used, this can cause a component to fail, which can negatively impact the entire package, or even cause an entire row or column to fail during testing or burn-in.

Final thoughts

When creating a flexible PCB for your project, it is important to understand the add-ons used with a flexible PCB. This is certainly the case with flexible PCBS and stiffeners. By understanding how these can be used with your flexible PCB, you will be better able to create efficient boards and have a greater chance of success. However, for flexible PCBS and stiffeners, you may have to ensure that you work with a qualified and experienced manufacturer of flexible circuits such as Taofang Electronics. Check out their website for more information on flexible PCBS.