Ultrasonic cleaning machine is the use of ultrasonic function to make the cleaning liquid hole effect, diffusion effect and vibration effect, the workpiece cleaning equipment, ultrasonic cleaning machine cleaning efficiency is relatively high, cleaning liquid can be cleaned into the smallest gap of the workpiece, so you can clean the bottom of the components, several small gaps between the components in the pollutants. The following patch processing manufacturers to explain how to ensure the quality of PCBA processing, how to choose the quality of PCB base board related knowledge.

1. How to select PCB substrate quality

1. Gold plate

Gold-plated plate process cost is the highest of all the plates, but at present all the existing plates are the most stable, but also the most suitable for use in the lead-free process of the plate, especially in some high unit price or the need for high reliability of electronic products are recommended to use this plate as the base material.

2.OSP board

OSP process cost is the lowest, easy to operate, but this process because of the need to modify the equipment and process conditions and heavy industry is poor, so the popularity is still not good, the use of this kind of plate, after high temperature heating, the protective film is bound to be damaged on the PAD, resulting in reduced solderability, especially when the substrate after the second back welding situation is more serious, Therefore, if the process needs to go through another DIP process, then the DIP end will face the challenge of welding.

3. Silver plate

Although "silver" itself has a strong mobility, resulting in leakage of electricity, but today's "silver dipping" is not the past simple metal silver, but with organic matter co-plated "organic silver" so has been able to meet the needs of the future lead-free process, its weldability of life is longer than OSP plate.

4. Gold plate

The biggest problem of this kind of substrate is the "black pad" (BlackPad) problem, so there are many big factories in the lead-free process is not agreed to use, but most domestic manufacturers use this process.

5. Tin plate

This kind of substrate is easy to be polluted and scratched, and the FLUX will oxidize and discolor. Most domestic manufacturers do not use this process, and the cost is relatively high.

6. Spray tin plate

Because of the low cost, good solderability, good reliability, the strongest compatibility, but this solder plate with good welding characteristics because it contains lead, so the lead free process can not be used. Another "tin silver copper spray tin plate" because most do not use this process, so it is difficult to obtain characteristic data.

2. How to ensure the processing quality of PCBA

Strict implementation of ISO9001:2008 quality management system, and in accordance with IPC-A-610E electronic assembly acceptance standards for production. The ISO review body strictly reviews the company's PCBA production quality control plan, establishes that the production site meets the standards and implements the prescribed quality control plan and measures. The audit includes the ability of production operators, production procedures and operation instructions, equipment compliance, raw material selection and warehousing, production documents, production site environment and safe assembly, node Settings in the production process, etc., forming a complete set of operation guidance plan. Class A substrate (general FR-4) is used.

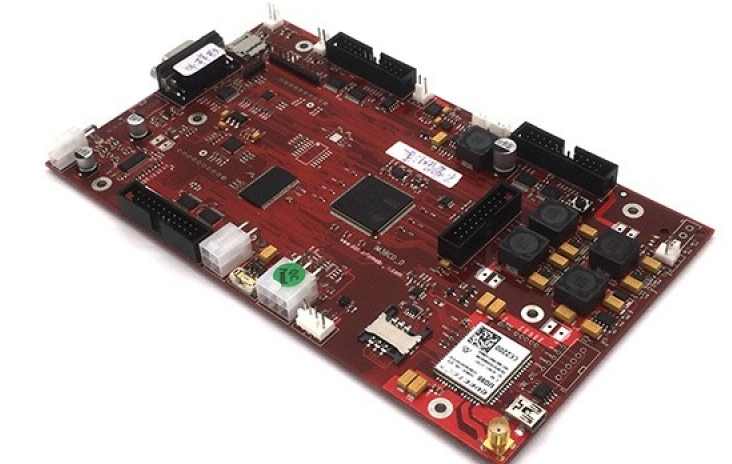

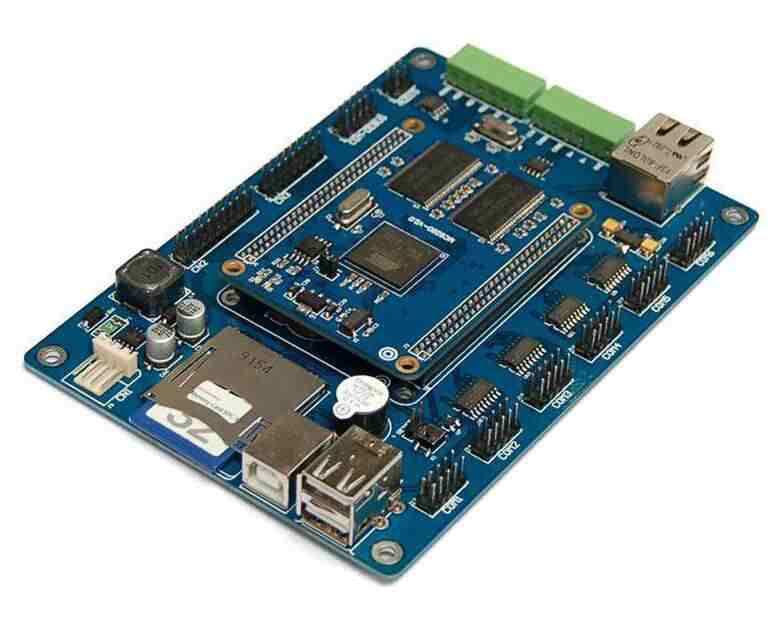

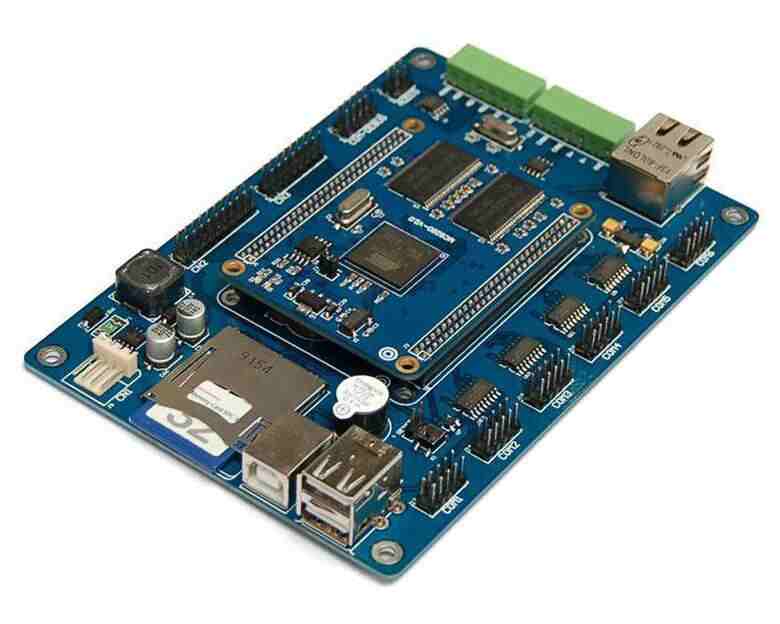

In the production process, fully automatic copper sinking wire and high-speed drilling machine to ensure high precision and fast delivery. All PCB circuit boards are tested by automatic high-speed flying needle tester to test the open and short circuit of the line, high voltage insulation and low resistance value conduction test, for mass PCB production, the use of professional supporting test rack to improve the test efficiency. Stable cooperation of electronic components brands and agents, Hou Sheng, Fenghua, Samsung, Guoju resistance capacitance; TI, NXP, CJ, Fujifilm, Fairchild, ST, Qualcomm, Micron, Infineon and other brand IC. Absolute original authentic components to ensure quality. High speed and high precision SMT SMT machine is the essential basis to achieve PCBA quality control, the use of high speed brand SMT machine, the maximum accuracy can reach 0402, to ensure the accuracy and speed of the patch. The reflow furnace in 10 temperature zone can make the solder paste get the best dissolution temperature and solidification temperature, so as to greatly improve the reliability of the patch, which becomes an important part of the quality control of PCBA.

Finally, AOI is used to detect the appearance of solder joints to ensure good tin on each material. Ultrasonic cleaning machine is the use of ultrasonic function to make the cleaning liquid hole effect, diffusion effect and vibration effect, the workpiece cleaning equipment, ultrasonic cleaning machine cleaning efficiency is relatively high, cleaning liquid can be cleaned into the smallest gap of the workpiece, so you can clean the bottom of the components, several small gaps between the components in the pollutants. Establish a set of perfect ISO quality control system, each post in accordance with the operation instructions, to avoid the maximum human factors such as negative impact