Exception Handling in SMT Patch Processing

Intention

In order to effectively track abnormal surface mounting process problems, define the rights and responsibilities of relevant departments, improve the efficiency of handling abnormal accidents and reduce complaints;

paraphrase

SMT: SMT;

SMT patch processing process exceptions: due to the lack of technical SMT equipment (program) parameters, poor raw materials (main materials, auxiliary materials), design errors and other factors, process control fails, production efficiency fails to reach the predetermined goal, and SMT product quality exceeds the IPC acceptance standard, all events are called surface mount process exceptions;

Responsibilities

Engineering Department: analyze the causes of process abnormalities, determine the nature of abnormal accidents, and put forward suggestions for improvement;

R&D Department: explain the design principles and modify the design scheme;

Quality Assurance Department: provide quality data reports, respond to complaints and assign responsibilities;

Quality Planning Department: track the timely closure and stage control of problems at each stage, and assist in promoting R&D and improvement for process problems in combination with engineering analysis and risk assessment;

After sales Service Department: respond to customer information, investigate and track customer product status;

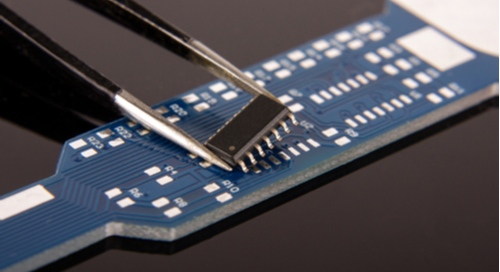

Circuit board

Project Management Department: comprehensively coordinate and supervise the members of the project team, promote the solution of problems, and ensure the progress of the project;

1. Processing flow of abnormal process caused by manufacturability design

1.1. In case of process abnormality caused by manufacturability design, the outsourcing factory will summarize the problem points and output the trial production report, and the NPI of the factory will send the trial production report to the project team. For the design for manufacturability problems reported in the "trial production report", the Engineering Department shall confirm whether to revise, and provide analysis and evaluation opinions to the R&D Department;

1.1.1 If the R&D Department has no objection to the analysis opinions of the project, the R&D Department will implement the revision, the quality plan will track the revision progress, and the project will be responsible for the revision and confirmation;

1.1.2. If there is a dispute between the analysis opinions of the project and the R&D and design requirements, the project manager and the quality plan will evaluate and resolve it;

2. Process exception handling during production

2.1. When abnormal process is found in production, NPI of XX Factory needs to confirm the status of the production line in a timely manner. PQE of the factory timely provides the "Outsourcing Factory Abnormal Problem Feedback Form". The project is responsible for judging, confirming and providing improvement suggestions according to the "Outsourcing Factory Abnormal Problem Feedback Form". PQE decides whether to maintain production or stop production according to the abnormal risk level;

2.2. Classification and handling of process exceptions during production

2.2.1. Handling of process abnormalities caused by defective incoming materials

2.2.1.1. Incoming error information feedback

2.2.1.1.1 For abnormal process accidents caused by defective incoming materials, the PQE of XX Factory is responsible for the information feedback of abnormal incoming materials, and notify the SQE to contact the supplier to cooperate with the production line for improvement;

2.2.1.2. Analysis of reasons for defective incoming materials

2.2.1.2.1. The resident PQE guides the analysis of outsourcing factories and suppliers to the production line and provides the analysis results;

2.2.1.2.1.1. If the outsourcing factory and supplier agree with each other and confirm the analysis results agreed by both parties, the project will give risk assessment opinions based on the analysis results of both parties and provide them to PQE for reference, and PQE will decide whether to change the data or overcome production;

2.2.1.2.1.2. If there are differences between the outsourcing factory and the supplier, and the two parties do not reach an agreement on the analysis results, the project will judge and analyze according to the abnormal echo information, and provide the analysis opinions to the PQE for reference, and the PQE will coordinate with the SQE to resolve;

2.2.2. Process exceptions caused by lack of processing technical data

2.2.2.1. Missing Gerber data content processing

2.2.2.1.1 The resident NPI will notify the project team via email, and the SMT process engineer will confirm. If it is true, the R&D Department will be responsible for upgrading the files and sending them to the outsourcing factory, and the New Product Import Department will be responsible for tracking until the problem is solved;

2.2.2.2. Handling of missing contents in "process control matters"

2.2.2.2.1 Shanghai NPI is responsible for upgrading the files and sending them to the outsourcing factory, and stationed NPI to supervise the outsourcing factory to adjust the process according to the upgraded files to maintain production;

2.2.3. SMT equipment (program) problem causes abnormal processing

2.2.3.1. Process abnormality handling caused by equipment efficiency decline

2.2.3.1.1. When the effectiveness of the SMT equipment of the outsourcing factory is not fully maintained and upgraded within a fixed period of time, resulting in abnormal process accidents, engineering intervention is required to evaluate the effectiveness of the equipment, instruct the outsourcing factory to modify according to the inherent parameters of the equipment, and then determine the equipment performance index (CPK) to meet the premise of XX product process capability;

2.2.3.2. Process abnormality treatment caused by sudden equipment failure

2.2.3.2.1. Process exceptions caused by sudden equipment failure during production shall be controlled by the outsourcing factory;

2.2.3.3. Processing exceptions caused by SMT patch errors

2.2.4. Handling of abnormal process caused by wire mesh opening method

2.2.5. Handling of abnormal process caused by auxiliary fixture (carrier dispensing fixture)

2.2.5.1 The outsourcing factory is responsible for proofreading and adjusting the auxiliary fixture, XX project is responsible for outputting specific requirements and evaluation opinions, and PQE is responsible for handling the quality problems caused thereby;

3. Process Exception Complaint Handling Process

3.1. For complaints about process abnormalities, it is necessary to coordinate and handle quality, engineering and R&D;

3.1.1 The Engineering Department and the R&D Department are responsible for the cause analysis and status confirmation of process exceptions;

3.1.2. The quality planning is responsible for coordinating and tracking complaints about process exceptions until the causes of exceptions are clear;

3.1.3. PQE shall guide the outsourcing factory to provide improvement measures according to the analysis conclusion of R&D and engineering, and track the follow-up production until the problem is solved; If verification by a third-party manufacturer is required, PQE will be responsible for coordinating the handling of outsourcing plants and providing analysis reports;

3.2. Process for Handling Internal Complaints with Process Exceptions

3.2.1 Handling of complaints about process abnormalities during R&D and commissioning

3.2.1.1. First, the R&D Department will conduct qualitative analysis of functions and signals, retain defective samples (without maintenance), fill in the "PCBA Welding Abnormity Problem Contact Form" and submit it to the quality plan, and then the quality plan will contact the engineering for analysis and judgment;

3.2.2. Handling of complaints about process abnormalities in the whole machine assembly stage

3.2.2.1 After sales service is responsible for collecting back-end information, PQE is responsible for summarizing production data of outsourcing factories, and the project is responsible for analysis and judgment;

3.3. Process of handling customer complaints in abnormal process

3.3.1 Abnormal information collection and echo

3.3.1.1 After sales is responsible for collecting and responding to customer information. The "Customer Complaint Handling Form" must describe the customer's operation process in detail (such as PCBA status, packaging and transportation pipeline, operation method, etc.), and attach clear pictures and explanatory text;

3.3.1.2. PQE is responsible for summarizing the production data of outsourcing factories, providing defective samples (without maintenance), and contacting the engineering and R&D departments for analysis;

3.3.2 Analysis and handling of abnormal causes

3.3.2.1 PQE shall organize meetings to determine whether the causes of customer complaints are sufficient and whether the complaint requirements are reasonable;

3.3.2.1.1. If the cause of the complaint is established and the customer complaint is obviously caused by abnormal process, PQE is responsible for urging the outsourcing factory to review and submit the subsequent improvement plan, and the project is responsible for confirming the improvement plan;

3.3.2.1.2. If the reason for the complaint is invalid and cause of the abnormality is relatively vague, the Quality Planning Committee shall notify the R&D Department to conduct qualitative analysis of functions and signals, fill in the "PCBA Welding Abnormity Problem Contact Form", "Project Based on" PCBA Welding ", analyze the abnormal problem contact form and give a judgment conclusion;