Selection of Packaging and Production of SMT Wire Mesh

Benefits of Choosing the Right Package SMT Chip Processing

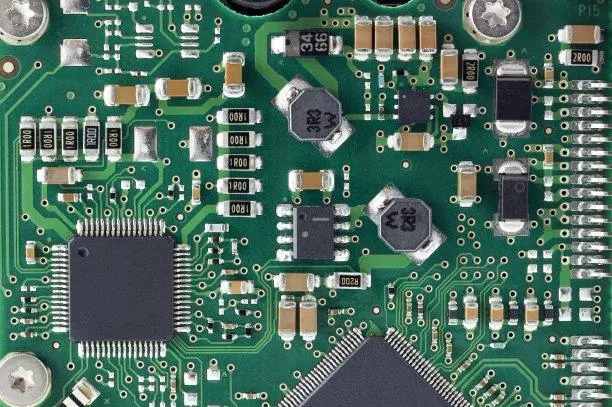

SMT surface mount components are functionally no different from components. The difference lies in the packaging of components. Surface mounted packages must be able to withstand high temperatures during welding, and their components and substrates must have matching thermal expansion coefficients. These factors must be fully considered in product design.

The main advantages of selecting an appropriate SMD processing package are:

1. Effectively save PCB area;

2. Provide better power efficiency;

3. Protect the interior of components from moisture and other environmental influences;

4. Provide good communication;

5. It is conducive to heat dissipation, transmission and testing.

Selecting and designing SMT surface mount components is a key part of the whole product design The designer determines the power efficiency and function of components in the system structure and detailed circuit design phase In the SMT design stage, it shall be based on the specific conditions and conditions of equipment and process The overall design requirements determine the packaging form and structure of surface mount components

The surface mounted solder joint is both a mechanical connection point and an electrical connection point. Reasonable selection will have a decisive impact on improving PCB design density, productivity, testability and reliability.

Precautions for production and acceptance of wire mesh in SMT chip processing plant

SMT wire mesh is a special mold in SMT processing. Its main function is to help solder paste deposit. The purpose is to transfer the exact amount of solder paste to the exact position on the empty PCB. SMT wire mesh plays an important role and affects the pasting effect. The quality of film processing. There are strict standards for the production and acceptance of wire mesh. The following Jingbang SMT processing plant will introduce the production requirements and acceptance precautions of SMT wire mesh.

1. SMT wire mesh production requirements:

1. According to the relevant documents and data provided by the Engineering Department, the supplier is required to make wire mesh.

2. The steel wire mesh shall be marked with the product model, thickness, production date, etc.

3. The frame size of wire mesh is required to be 550MM × 650MM × 370MM × 470MM, etc., mainly determined according to the structure and product specifications of the printing machine.

4. Thickness of wire mesh (scraper is generally 0.18MM-0.2mm, tin plating is generally 0.1MM-0.15MM).

5. The opening method and size of the wire mesh (tin bead is generally V-shaped, U-shaped, concave, etc., depending on the type of each component.)

6. The direction of the plate and the mounter shall be uniform.

2. Precautions for acceptance SMT wire mesh:

1. Check whether the method and size of wire mesh opening meet the requirements.

2. Check whether the thickness of wire mesh meets the product requirements.

3. Check whether the size of wire mesh skeleton is correct.

4. Check whether the marking of wire mesh is complete.

5. Check the flatness of the wire mesh.

6. Check whether the wire mesh tension is good.

7. Check whether the position and number of openings in the wire mesh are consistent with those in the GERBER file.

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.