Automatic smt processing, welding and maintenance

When it comes to smt processing, the importance of fully automated production lines is well known After all, it provides the mass storage required for efficiency and consistency in PCB manufacturing The current market demand makes automatic assembly more important than ever before Obviously, its importance comes from its high efficiency and high quality, which makes it easier to enter the market Therefore, it can become an important source of competitive advantage Other key advantages it provides include:

1. Low cost

Professional smt wafer processing plants use the circuit board assembly program before entering the actual production. In turn, this reduces the possibility of errors and delays. During this period, any design errors can also be corrected. In general, this will greatly reduce costs.

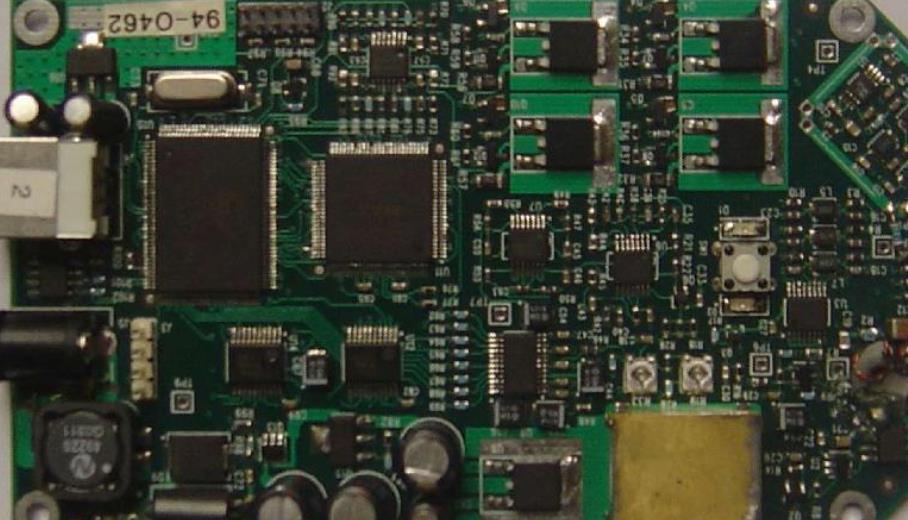

Polychlorinated biphenyl manufacturing

2. Reduce the chance of error

The PCB assembly process requires great attention to detail. This is especially true given that circuit boards are getting smaller and smaller. Automatic patch assembly significantly reduces the chance of errors. This means that you can get reliable products without having to face costly mistakes when preparing to ship the final product.

3. Consistent quality

Circuit board

A major advantage of automatic assembly is that it ensures consistent quality. This is also one of the advantages of entering industrialized mass production.

4、 Miniaturization

With the miniaturization, it is usually impossible to assemble parts manually, and the assembly process needs to be automated. In addition to these general advantages of automatic assembly, PCB automatic assembly also benefits from the following facts in particular:

1. Large parts need automatic reflow soldering, because it is very difficult to solder pins manually, especially the pins hidden below.

2. QFP is very sensitive to coplanarity and difficult to weld manually.

3. It is difficult to weld small parts such as resistance and capacitance manually.

4. For circuit boards with dense components, the consistency of manual welding is always a problem.

Some of the automation systems used by contract manufacturers include:

1. Picking and placing machine for placing parts on the circuit board;

2. Welding system for placing parts;

3. Automatic wiring machine;

6. In addition to the assembly system, there is an automatic test system, including:

1. Optical detection system;

2. On line test system;

3. Flying needle test system;

4. Function test system;

Advantages of automatic chip mounting production line

Lead free soldering and rework smt processing

The introduction of lead-free chip assembly has always been the challenge of the first assembly, because when PCB processing and rework are required, it will face more challenges. The maintenance of PCBs in a lead-free environment will have higher costs, quality details, time and repeatability issues, but due to the lead-free requirements, all these issues need attention. Because lead-free process requires:

1. Train operators to perform lead-free assembly, maintenance and inspection, and evaluate time and cost.

2. Lead free solder is more expensive than traditional solder, such as lead-free wire, electrode and core solder.

3. The processing temperature of lead-free components (about 30-35 ℃) requires higher accuracy and precision.

4. Lead free process also needs to study and plan smt processing plant to establish correct PCB rework process

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.