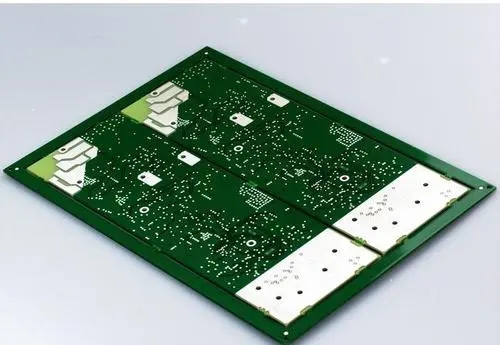

How to repair and maintain the circuit board

During the production and use of SMT chip processing, problems occurred in the whole PCBA manufacturing process and use process, including processing errors, improper use, aging of components and other factors, which may lead to abnormal operation or even poor use of the real product. Because many products just don't need to be replaced completely.

During the production and use of SMT chip processing, problems occurred in the whole PCBA manufacturing process and use process, including processing errors, improper use, aging of components and other factors, which may lead to abnormal operation or even poor use of the real product. Because many products just don't need to be replaced completely. This requires certain repair and maintenance of the circuit board inside. Generally, the maintenance technician in the patch processing plant will perform the following operations.

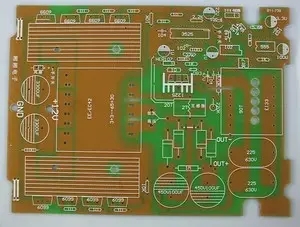

1. Check components

When the products in the SMT chip processing plant need to be repaired, it is necessary to first determine whether there are errors, leaks and reverse problems in the components of each solder joint. It is also a case to be considered to confirm that there is no authenticity of materials. In view of the fact that Jingbang Electronics imported chips from Sweden in 2011, the supply of European and American countries is not necessarily better than Huaqiang in the north. If the problems of error, leakage, inversion and authenticity are eliminated, you can get a faulty circuit board and first check whether the circuit board is in good condition, whether the components are obviously burned out and whether they are inserted incorrectly.

2. Welding state analysis

About 80% of the defects of the circuit board are basically the defects of the solder joints. Whether the solder joints are full and whether there are abnormalities, first of all, refer to the management standards of the ISO9001 quality system, as well as various SMT processing and welding quality standards, and check whether there are any defects visible to the naked eye, such as false solder joints, short circuits, and whether the copper sheet is obviously cocked. If there is any, you need to repair the defective points of this product. If not, you can proceed to the next step!

How to repair and maintain the circuit board in SMT chip processing and production

3. Detection of component direction

In the process of this link, we have basically eliminated some defects that can be seen by the naked eye. Now we should carefully check whether the most used components on the circuit board, such as diodes and electrolytic capacitors, and other components with specified directions, or the components with required positive and negative electrodes, are inserted in the wrong direction.

4. Tool inspection of components

If all visual judgments are correct, we need to borrow some auxiliary tools at this time. The most common thing in SMT chip processing plants is to simply measure our resistance, capacitance, triode and other components with a multimeter. The most important thing to check with a multimeter is to check whether the resistance and resistance of these components are not in line with the normal value, whether the capacitance is open circuit, Whether the inductance is open circuit, etc.

5. Power on test

After all the above processes are completed, the common problems of components can be basically eliminated, and the circuit board will not be damaged due to ablation due to short circuit or bridging when powered on. Then you can turn on the power and check whether the corresponding functions of the circuit board are normal.