How to select a qualified SMT chip processor?

It is believed that many smt companies that need to process SMT chips do not have a standard when looking for SMT chip processing plants. It is OK to find a suitable price, or almost all aspects, but this often leads to a judgment on whether a SMT chip processing factory is really qualified. In terms of price alone, if a SMT chip processor's quotation is significantly lower than the market cost price, there must be a problem. Therefore, it is one-sided and far fetched to judge from the price alone. In addition to the price we are more concerned about, what other aspects can we investigate SMT chip processing plants? That is to say, how to choose a qualified PCBA processing plant?

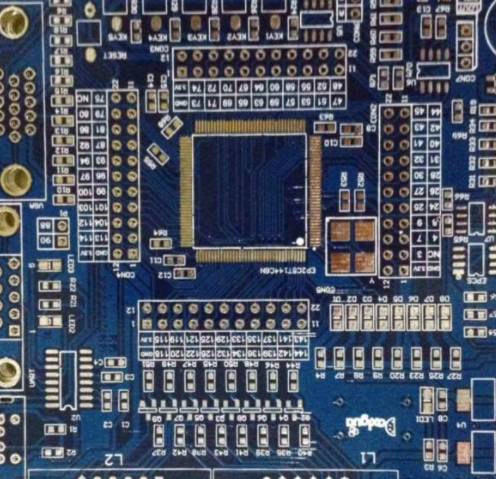

1、 Importance of SMT chip processing plant equipment

A qualified SMT chip processing plant must have complete processing equipment. The equipment configuration directly determines the production capacity and quality of SMT processing, ensuring that each step of quality inspection can be achieved in each processing link. It can fully implement BGA/IC and other precision mounting and testing. Therefore, whether a SMT chip processing factory has complete equipment and qualified operation technicians, and whether Nissan can meet the production needs of its own products, can be judged by the equipment provided by the company. The capacity of SMT chip processing plants is mainly shown in SMT workshops, which generally need to be configured in more than 5 lines to basically meet the shipping needs of each different customer, and the 1H capacity of each line needs to reach more than 70000 points. The testing equipment is equipped with steel mesh tension tester, SPI, first article tester, online AOI, offline AOI, X-ray, push-pull tester, 500x micro magnifier, etc; Therefore, for a qualified SMT chip processing plant, equipment allocation is the most important criterion.

Chip processing plant equipment

2、 Importance of SMT chip processing plant team

A high-quality circuit board is completed by a group of people, including engineers, procurement, quality, warehouse, production department, etc. To achieve excellent quality and fast delivery, a team with excellent engineering technology, strong purchasing strength, meticulous quality inspection and orderly warehouse management is essential. SMT processing is a process that requires close, efficient and coordinated by multiple departments. That is to say, it extends to the collaboration among various departments. The six key points of the team are safety production, functional training, quality control, delivery time, cost control and team appearance. These six key points constitute the capillaries of SMT patch processing plants, which are the basic criteria to ensure the delivery time and product quality of products, and are of great significance in the processing of circuit board patches. A good team should have comprehensive safety production awareness, accurate delivery and production planning, refined cost management concept and strict product quality control requirements. Importance of the team We need to conduct a comprehensive review when assessing the SMT chip processing plant, including the document production process, environmental sanitation, quality control nodes, material control, staff's mental outlook, etc; These elements are all about the quality of product processing.

3、 Importance of SMT chip processing plant management

The key process in the SMT chip processing plant needs to be carefully managed in the processing quality management. SMT patch processing technology is relatively complex, and the details are also quite numerous and cumbersome. In order to improve the patch processing quality, we must formulate various details and precautions in the production process, and deal with them in strict accordance with the patch processing requirements. The importance of management is attached great importance in every factory, including all details. It is advocated by the top leader and implemented by the person in charge. High chip processing quality and good staff service attitude are the key points for survival of a SMT chip processing factory. In other words, a good team can not be separated from a good leader.

The above is the explanation given by the editor of pcb circuit board company. If you want to know more about PCBA, you can go to our company's home page to learn about it. In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.