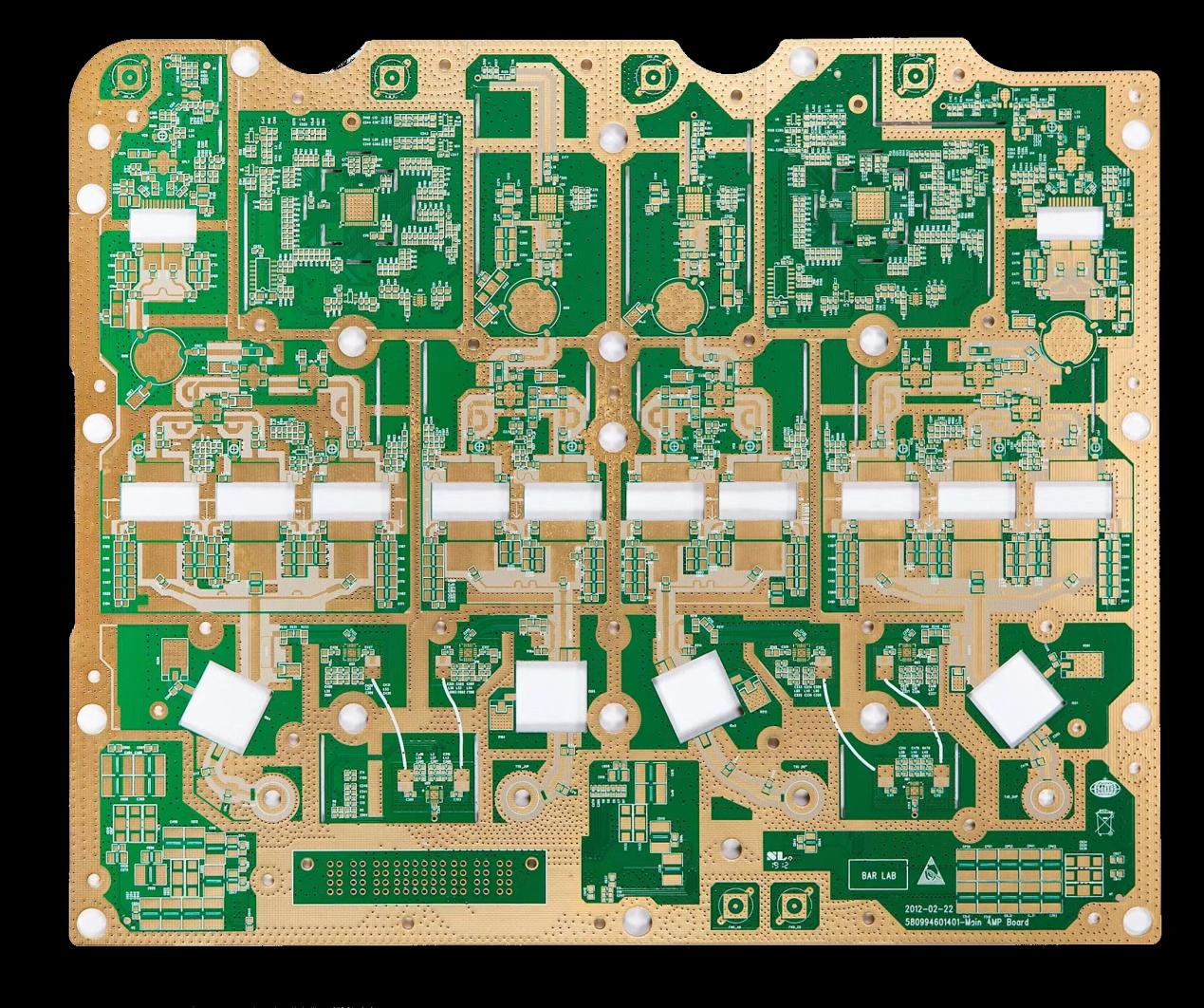

Overall,flexible PCBs and high-density interconnection boards (HDI) are the two major highlights of the PCB market growth in the past two years. On the one hand, under the current trend of major brands rushing to the wearable electronics market, it has brought a lot of business opportunities toflexible PCB manufacturers; The consumption also showed an upward trend. Driven by the replacement effect of 4G communication mobile terminals, a number of major high-end circuit board manufacturers have actively expanded their production capacity to meet the rapidly rising market demand.

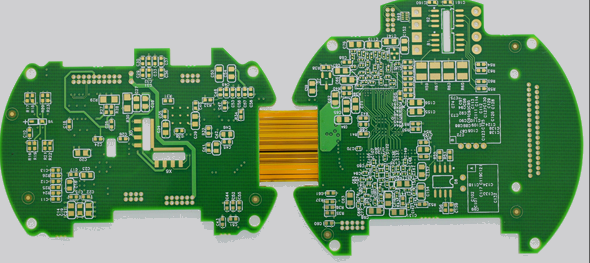

For example, folding mobile phones have been regarded as an industry direction. This year, as Huawei, Huawei, Samsung, Royole and other manufacturers have officially released folding screen mobile phones, Xiaomi, OPPO, vivo and other manufacturers have also come up with related folding screen mobile phones. prototype. The first year of folding mobile phones has begun. Among them,flexible PCBs have become an indispensable component of folding mobile phones due to their light weight, thin thickness, and good bendability. However, the application of FPC (flexible circuit board) in smart phones still faces many technical difficulties, which will become the focus of current manufacturers to overcome.

FPC has the characteristics of lightness, thinness, bendability, winding, foldability and high wiring density, which perfectly fits the development theme of lightness, thinness and miniaturization. FPC is mainly used in mobile terminals, consumer electronics, automotive electronics, industrial control, medical, aerospace and military. Among them, the mobile terminal category is the largest application field of FPC, especially smart phones, which is also the field with the highest requirements for FPC technical capabilities, and will also lead the technical development direction of FPC in the future. The development trend of miniaturization and intelligence will make flexible mobile phones a trend in the future.

Experts also put forward solutions to the requirements of FPC for folding, connecting and multiple use of folding screens. In a mobile phone with a flexible screen, due to the need to fold it multiple times and a large number of times, the requirements for the flexible PCB inside the mobile phone will be higher, and the corresponding use area will be further increased. However, FPC is usually manufactured by a batch process, so it is limited by the size of the production equipment. In response to this problem, experts believe that it can be extended through the middle socket, and the FPC can be reinforced by pulling and inserting gold fingers.

The increasing application of FPC in mobile phones will become an established trend, which also makes the FPC market show a favorable trend. However, FPC still faces pcb manufacturing problems, such as the application of large size in folding screen mobile phones. Of course, there are corresponding solutions for these problems, but these solutions inevitably bring about an increase in cost. How to better control the cost of FPC can only be solved by mass production or technology upgrade.