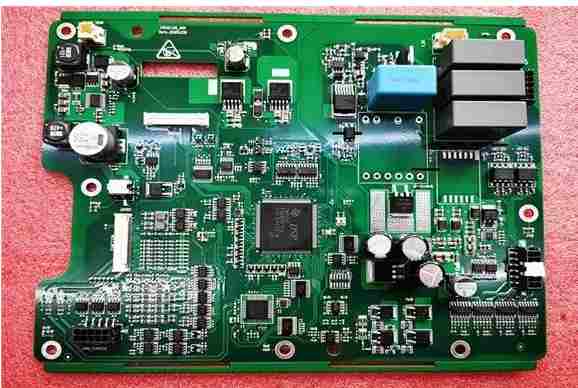

There are three requirements for PCBA processing

With the development of science and technology, many electronic products are developing in the direction of small and fine, which makes the size of many patch components smaller and smaller.

Not only the requirements of the processing environment continue to increase, but also the SMT processing technology has higher requirements. To do a good job of PCBA processing and SMT processing plants need to do at least the following three points.PCBA processing needs to do three requirements.

First, in the process of SMT processing, we all know that we need to use solder paste.

For the solder paste just purchased, if it is not used immediately, it must be stored in an environment of 5-10 degrees. In order not to affect the use of the solder paste, it should not be placed in an environment below zero.

Second, the SMT equipment must be checked frequently during SMT processing.

If the device is aged or some parts are damaged, in order to ensure that the patch does not bend, it must be repaired or replaced with a new device. Only in this way can we reduce production costs and improve production efficiency

.

Third, in the process of SMT processing, if you want to ensure the quality of PCB welding, you must always pay attention to whether the setting of reflow process parameters is very reasonable.

If the parameter setting is wrong, the quality of PCB welding cannot be guaranteed. Therefore, in general, the furnace temperature must be tested twice a day, at least once. Only by continuously improving the temperature curve and setting the temperature curve of welding products can the quality of processed products be guaranteed.

Summarize

This article highlights three key requirements for successful PCBA processing. It stresses the importance of proper solder paste storage, regular checks on SMT equipment for maintenance, and continuous monitoring of reflow process parameters, particularly furnace temperatures. These measures are crucial for ensuring efficient and high-quality PCB assembly in the rapidly advancing landscape of electronic component miniaturization.