PCBA OEM needs to understand the risks

PCBA OEM is to provide all the information needed for the entire electronic processing to the electronics processing plant, and then wait to receive the goods, which is a very convenient and worry free processing mode. After SMT patch proofing processing and PCB plate making, purchasing materials and other links are handed over to the SMT patch processing plant, those tedious links are eliminated, and the rest of the energy can be better placed on product research and development and market development. Everything has advantages and disadvantages, and it seems that the processing mode is very convenient, which must be risky, then what is the risk?

Maintenance Risk

If PCBA OEM manufacturers do not have strong maintenance capabilities, resulting in product maintenance difficulties, extended maintenance cycle, will eventually affect the product delivery time, causing relatively large losses to customers.

Quality Risk Of Materials

SMT patch processing plant, those tedious links are eliminated, and the rest of the energy can be better placed on product research and development and market development. Everything has advantages and disadvantages, and it seems that the processing mode is very convenient, which must be risky, then what is the risk?

Maintenance riskf PCBA OEM manufacturers do not have strong maintenance capabilities, resulting in product maintenance difficulties, extended maintenance cycle, will eventually affect the product delivery time, causing relatively large losses to customers.

PCBA OEM manufacturers are overall responsible for the manufacture of electronic components and PCB boards, some profit-seeking electronics processing plants may buy some fake and shoddy materials in order to reduce production costs.

Procurement Cycle Risk

In the entire production cycle of electronic processing, material procurement is the most unstable, especially when the components used by customers are relatively scarce, not common supplies or components are in large demand, and the OEM has no inventory and needs to order, at this time, uncontrollable factors will occur.

Capital risk PCBA OEM mode requires processing manufacturers to help customers buy all materials, customers need to pay advance payment, generally 70% of the overall payment in advance, and then the manufacturer begins to purchase materials, electronic processing production process, and finally, the customer pays the remaining 30% when the product is shipped. In general, this is a good processing model, but the customer needs to find a contract factory with many years of experience and strict quality control. PCBA OEM needs to understand the risks

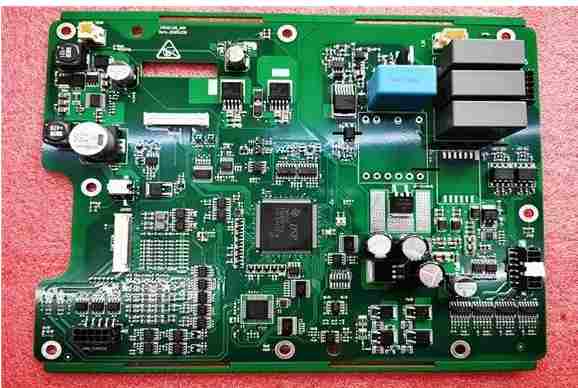

Shenzhen Kingford Technology Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistors, capacitors, inductors, audiodes and other components procurement advantages, can greatly save customers' inventory costs, improve production turnover efficiency, save time. Currently for the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions to provide PCBA processing services.

Strength Guarantee

▪SMT workshop: With imported SMT machines, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

Quality assurance, cost-effective

▪ High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand. ▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 CNY/point, no start-up fee.

Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated services for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers.

▪ Punctual delivery, 3-5 days after the materials are complete, small batches can also be expedited on the same day.

Strong Maintenance Ability, Perfect After-Sales Service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each circuit board.

▪ 24-hour customer service staff responds at any time to solve your order problems as quickly as possible.