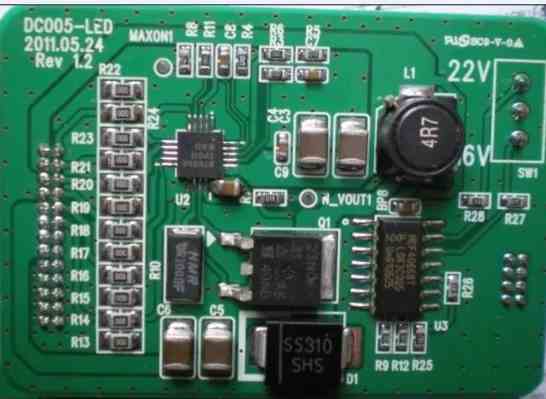

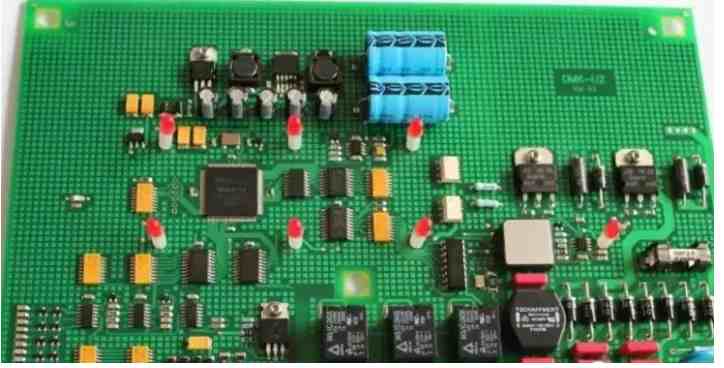

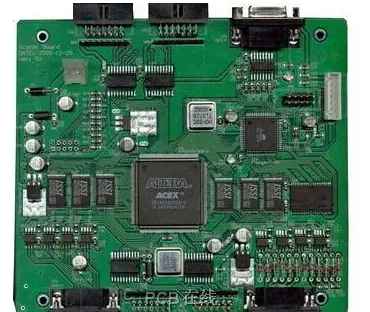

SMT (Surface Mount Technology) is a production process widely used in the manufacture of electronic products. Compared with the traditional TH (Through-Hole) plug-in processing technology, SMT chip processing has the following advantages:

1.Miniaturization: SMT components are small in size and light in weight, which can achieve more miniaturized and lightweight product design. This is especially important for some electronic devices that need to be portable and compact.

2. High integration: SMT components can be highly integrated through printed circuit boards (PCBS), thereby improving product functionality and performance.

3. High speed: SMT chip processing can be automated, so the production speed is faster, greatly shortening the manufacturing cycle of the product and improving production efficiency.

4. Reliability: The connection method of SMT patch processing is welding, which is more reliable than plug-in connection. At the same time, SMT components can achieve more pin connections on the PCB, thus improving the stability of the connection.

5. Low cost: SMT chip processing can achieve large-scale automated production, which can effectively reduce production costs.

Therefore, SMT chip processing plays a very important role in modern electronic product manufacturing, which can achieve the advantages of miniaturization, high speed, high reliability, high integration and low cost.

kingford has its own SMT processing plant, which can provide SMT processing services for 0201 components in the smallest package. The SMT plant is equipped with 3 Fuji high-speed SMT lines, 2 DIP plug-in production lines, equipped with AOI optical detector, automatic solder paste printing machine, semi-automatic solder paste printing machine, lead-free wave soldering, lead wave soldering, upper and lower 8 temperature zone reflow welding, PCBA functional test frame, aging, board loading machine, cleaning tools, etc., at the same time, a professional research and development laboratory is set up. Five professional engineers cooperate with customers to perform general functional testing, test point testing, as well as channel, noise, waveform, drop and temperature testing.

1.Manual cleaning method

Manual cleaning method is one of the simplest and most primitive methods to remove excess tin residue. It is mainly manually operated, using hand tools (such as scissors, scrapers, spray guns, etc.) to clean up excess tin residue. The advantage of this method is that it is simple and easy, does not require any equipment and materials, and only requires operators with certain skills and experience. In addition, the manual cleaning method can be personalized for different PCB boards and tin slag, with high flexibility and plasticity. However, the manual cleaning method also has many shortcomings, such as low efficiency, easy to make mistakes, high work intensity and low precision. Moreover, if the cleaning is not thorough, some small tin slag and stains may be left, affecting the quality and reliability of the PCB surface.

2. Solvent cleaning

Solvent cleaning is a commonly used method to remove excess tin residue. It is mainly through chemical reaction, the use of solvents to dissolve or separate the excess tin residue. In general, commonly used solvents include acids, bases, organic solvents and so on. The advantages of this method are high cleaning efficiency, the cleaning process will not cause damage to the PCB surface, and it is suitable for various PCB boards and tin slag. Moreover, the solvent cleaning method can also add some surfactants or emulsifiers to improve the cleaning effect and stability. However, the solvent cleaning method also has some shortcomings, such as low safety, complex operation and high cost. In addition, due to the uncertainty of the chemical reaction, the cleaning effect is also different.

3. Sticky tape cleaning method

Viscous tape cleaning is a commonly used method to automatically remove excess tin residue. It mainly sticks the adhesive tape to the PCB surface, sticks the excess tin slag to the tape, and realizes the purpose of automatic cleaning. The advantages of this method are high cleaning efficiency, high cleaning accuracy, and suitable for various PCB boards and tin slag. Moreover, the viscous coil cleaning method can achieve continuous automatic cleaning, improve production efficiency and quality stability. However, the adhesive tape cleaning method also has some disadvantages, such as higher cost, requiring more equipment and maintenance costs. In addition, for some relatively small tin slag or hard-to-reach locations on the PCB surface, the adhesive tape cleaning method may not be suitable.

4. Aerosol cleaning methodAerosol cleaning is a commonly used method to remove excess tin residue. It is mainly by spraying a chemical cleaning agent on the PCB surface, and then rinsing excess tin slag from the surface through compressed air. The advantages of this method are high cleaning efficiency, high cleaning accuracy, and suitable for various PCB boards and tin slag. Moreover, the aerosol cleaning method will not cause damage to the PCB surface, and the solubility and fluidity of the cleaning agent can also be effectively controlled. However, the aerosol cleaning method also has some disadvantages, such as high equipment cost, complex operation, and environmental and health effects.

5. Paint cleaning methodPaint cleaning method is a novel method to remove excess tin residue. It mainly achieves the purpose of cleaning by coating a layer of paint on the PCB surface, and then after the paint dries, the excess tin slag and paint are stripped together. The advantages of this method are high cleaning efficiency, high cleaning accuracy, and less impact on the PCB surface and the environment. Moreover, the coating cleaning method can be customized according to different PCB boards and tin slag, improving the cleaning effect and stability. However, the paint cleaning method also has some shortcomings, such as complex operation, the need for certain technology and experience, and the high cost of paint.