In today's electronic technology focus, PCBA has become an exponential growth industry. PCBA is an important part of the electronics industry and is the process of composing all electronic components into a circuit board. Today, there are a wide variety of PCBA manufacturers on the market, and choosing a good PCBA manufacturer is a very important step for companies that need to produce mass electronic products.

So how to choose an excellent PCBA manufacturer? Here are some suggestions.

1.Word of mouth and reputation

First of all, customers should consider the reputation and credibility of PCBA manufacturers. Only good reputation and reputation, can show that this manufacturer has better production and quality control capabilities, customers can rest assured that important orders to them. You can refer to the manufacturer's history, user reviews, and suggestions from other customers.

2. Quality management system

Secondly, excellent PCBA manufacturers need to have a complete quality management system to ensure product reliability and consistency. The best way to do this is to ask the PCBA manufacturer if they have ISO 9001 quality management system certification or other industry certifications.

3. Production capacity

Third, customers need to consider the production capacity and production scale of PCBA manufacturers. The larger the production capacity and scale, the easier it is to provide customized services, better prices and on-time delivery. The customer needs to confirm whether the manufacturer can handle a large order.

4. High cost performance

Fourth, high cost performance is an important factor in choosing a PCBA manufacturer. Under the premise of reasonable prices, PCBA manufacturers are required to provide high-quality service, more refined processes and more reliable products.

5. Technical service

Finally, the technical service of PCBA manufacturers is also an important selection criterion. Customers need to confirm that superior technical support is available and provide a quick response when needed.

To sum up, according to the above selection criteria, customers can choose a reputable, has a complete quality management system, strong production capacity, with high cost performance and excellent technical service PCBA manufacturers. In this way, it can ensure that customers' electronic products can have better quality and reliability, so that customers' business can be better developed.

In this way, choosing a good PCBA manufacturer is not a simple matter, and it needs to be completed successfully through various assessments and rigorous consideration. Customers need to clarify their needs, combined with the above points, comprehe SMT machinesnsive analysis, so as to get the best choice.

1. Strength guarantee

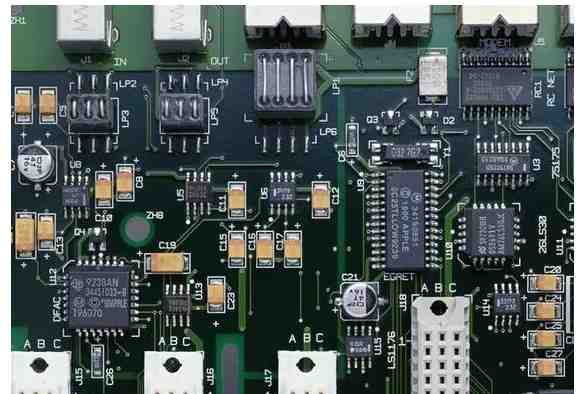

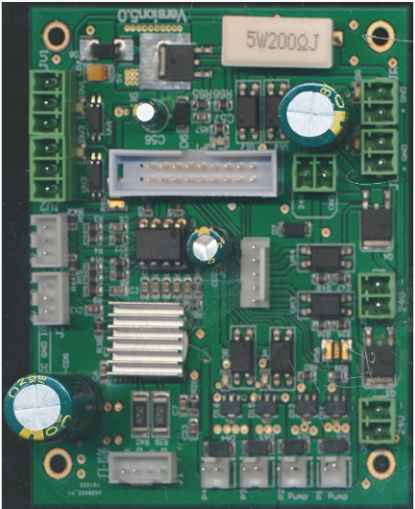

▪SMT workshop: With imported, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated service for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers.

▪ Punctual delivery, normal 3-5 days after complete materials, small batches can also be expedited on the same day.

4. Strong maintenance ability, perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each circuit board.

▪ 24-hour customer service staff responds at any time to solve your order problems as quickly as possible.