How does the SMT patch electronic component work?

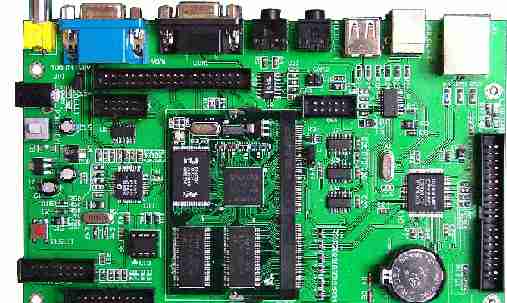

Manufacturing electronic products using surface mount technology (SMT) simply means assembling the electronic components with automatic machines that place the components on the surface of the circuit board (printed circuit board, PCB). Unlike traditional through-hole technology (THT) processes, SMT components are placed directly on the surface of the PCB instead of being soldered to the wires. SMT is the most widely used process in the industry for electronic assembly.

Electronic assembly involves not only placing and soldering parts onto the PCB, but also the following production steps:

Solder paste made of tin particles and flux is applied to the PCB

Place the SMT assembly in the solder paste on the PCB

Solder the circuit board by reflow soldering process.

Application of solder paste is the first step in the SMT assembly process. Solder paste is "printed" onto the plate using a screen printing method. Depending on the design of the board, different stainless steel templates are used to "print" solder paste on the board and solder paste specific to various products. Using laser-cut stainless steel templates customized for the project, the solder paste will only be applied to the area where the components will be welded. After placing the solder paste on the board, a 2D solder paste check is performed to ensure that the solder paste is applied correctly and evenly. Once the accuracy of the solder paste application is confirmed, the board is transferred to the SMT assembly line where the components are welded.

The electronic components to be assembled are placed on trays or spool and then loaded into the SMT machine. During charging, intelligent software systems ensure that components are not accidentally changed or loaded. The SMT assembler then automatically removes each component from its tray or spool using a vacuum pipette and places it in the correct position on the board using pre-programmed precise XY coordinates. Our machines can assemble up to 25,000 parts per hour. After SMT assembly is completed, the board is moved to the reflow furnace for soldering, thus securing the assembly to the board.

When welding electronic components, we use two different methods, each with different advantages, depending on the quantity ordered. For bulk production orders, the reflow welding process is used. During this process, the board is placed in a nitrogen atmosphere and gradually heated with hot air until the solder paste melts and the flux evaporates, thus fusing the components onto the PCB. After this stage, the board will cool down. As the tin in the solder paste hardens, the component sticks to the plate permanently, completing the SMT assembly process.For highly sensitive prototypes or components, we have a special gas phase welding process. In this process, the plate is heated until it reaches the specific melting point of the solder paste (Gordon). This allows us to weld at lower temperatures, or solder different SMT components at different temperatures according to different welding temperature curves. https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

AOI and appearance inspection

Welding is the penultimate step in the SMT assembly process. Visual AOI checks are performed on almost all volume production orders to ensure the quality of the assembled cards, or to find and correct errors. The AOI system uses multiple cameras to automatically examine each plate and compare the appearance of each plate to the correct predefined reference image. If there is any deviation, the possible problem is reported to the machine operator, who then corrects the error or removes the plate from the machine for further inspection. Visual AOI validation ensures consistency and accuracy during the production of SMT components.

kinhford Electronic Technology Co., Ltd. is a professional one-stop PCBA OEM service electronic components purchasing, SMT patch, DIP welding, complete assembly, testing, packaging one-stop comprehensive manufacturing factory. Welcome to contact us!