Smt patch machine online programming tutorial and re - editing tutorial

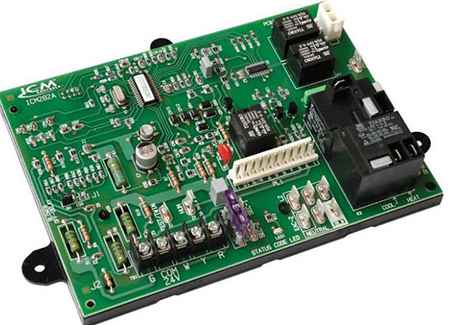

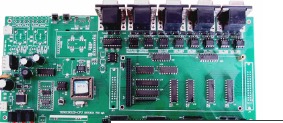

Smt SMT online programming refers to the use of part of the machine attached to the instruction for program editing and the use of the random application software of the SMT program editing function. The methods of online programming include instruction programming and manual input programming. In addition, it can also be used on the machine to mount coordinates of components on the circuit board and the database of components for instruction correction. Runze Wuzhou for everyone to share the details of Smt SMT machine online programming method: https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

I. Instruction programming of Smt placing machine

The traditional Smt Smt machine programming method uses the manual teaching mode of the SMT machine. The teaching box, namely the mobile camera, is used to find out the coordinate position of all the SMT components on the circuit board, and then the other information of the components, such as the bit number, code and mount Angle of the components, is manually input into the SMT SMT machine. Instruction programming is the simplest basic programming method, generally the old medium speed machine used this method. This takes up production time on the machine, and using manual instruction to find points on a circuit board with hundreds of chip components is a laborious and error-prone task.

(1) Feeding instruction: select the type of suction nozzle, use the teaching box to move the paste head to the top of the feeder, drop and pick up components, and determine the alignment mode. The control computer of Smt SMT machine processing will automatically record the X-Y-z-Q coordinates of feeding and other feeding correction modes. (2) Patch teaching: after material taking and teaching, component drawing, correction and Angle rotation, use the teaching box to move the sticker head above the welding pattern of the circuit board, use the circuit board recognition camera to determine the center of the component, and then lower the component to the circuit board, click input.

(3) Complete the transmission of the circuit board, the setting of the feeder and the nozzle, and the teaching of the position: after the teaching of the material taking and the teaching of the patch, the installation sequence programming and teaching can be carried out. The placement sequence programming can be done through the instruction box or can be optimized automatically using the automatic programming function included with the placement machine software.

2. Manual input programming of the patch machine

All SMT machines can be programmed with manual input. In the mounting list of programming software, after entering the bit number (RefID) of the component, select the component database code of the component, input the x, y coordinates and rotation Angle of the component, this has the most important information of the chip machine program. Then input a variety of different component codes of the station number, to optimize the installation sequence, the placement machine programming can be completed.

Three, patch marking teaching and correction

Because the exact coordinates for component mounting are sometimes not available and it would be troublesome to change the coordinates after the first board has been installed, some mounters also provide a component coordinate correction function, also known as Enhanced Product Setup. The enhanced program setting uses the machine's PEC camera to visually display the graphics of the position of the patch, which can effectively improve the precision of programming.

What if we need to edit the Smt mounter again?

First step: First system reprogramming: the system of the patch machine generally adopts two programming methods: manual programming and computer programming. SMT machine Many low-level SMT machines usually use manual teaching programming, and such as Hua Wei Guochuang SMT machine this fully active machine can completely use computer active programming.

The second step: replace the original feeder: in order to reduce the time for the feeder to be replaced by the laminator, the more common way is to use the "fast release" feeder, and the faster way is to replace the feeder structure, so that the feeder of each component on the substrate type of the laminator is installed on a separate feeder frame for replacement. Step 3: Adjustment of transmission organization and positioning platform: When the replacement of the substrate plate size is not consistent with the current device of the substrate plate size, the width of the substrate plate positioning platform and the transport organization of the substrate plate should be adjusted. Full active placement machine can be adjusted under program control, the next level of placement machine can be manually adjusted. Step 4: Replace the mounting head: The mounting head of the mounting machine is often replaced or adjusted when the type of component to be installed on the substrate exceeds the size of the device for placing the head, perhaps when the type of the substrate is changed. Most fully active SMT machines can actively perform replacement adjustment of the mounting head under program control, while some small brands of SMT machines need to perform this operation manually.

The above is the Smt placement machine programming tutorial provided by us. If you have any questions, please feel free to contact us.