CIMS is applied in SMT patch processing and produSMT productionction

For many electronic enterprises with smt equipment, the introduction of computer integrated manufacturing system cims into SMT patch processing and production has improved product quality and equipment utilization, and greatly shortened the product design cycle and the time of putting into the market. The economic benefits brought by cims to enterprises are obvious, and it is believed that cims will be more and more widely used in SMT patch processing and production in the near future.

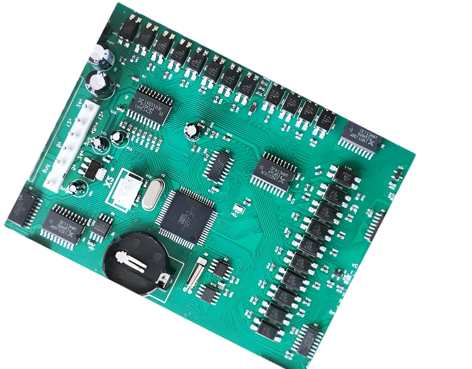

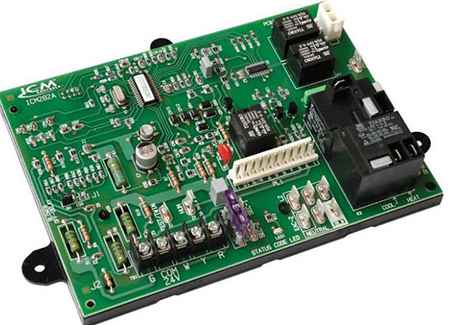

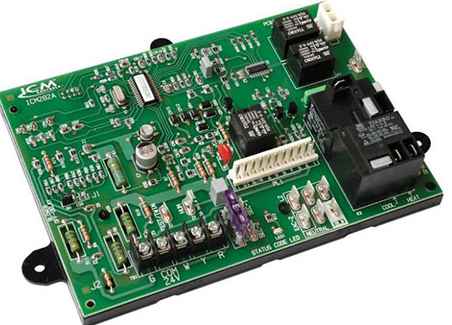

Many equipments in SMT line are automatic equipments controlled by computer, which makes it possible for cad/cam integrated system to be constructed by computer aided manufacturing. https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

The design department of modern electronic production enterprises almost all uses cad software for circuit design, and the production and manufacturing department also uses a large number of automatic equipment such as patch machine and DIP plug-in processing and inserting machine for production. However, the two departments rarely understand each other's needs, and many useful information cannot be shared, which often forms two "automation" islands between enterprises. With the intensification of market competition, customer demand for shortening product delivery cycle and control of production costs, it is urgent to establish a connection between these two islands in order to shorten production preparation time, strengthen pre-production defect analysis and reduce product repair. computer integrated manufacturing system (cims) is the only way to connect the information flow between cad design system and production automation, and remove the "partition wall" between product design and production.

Processing cad design documents, improve the assembly accuracy, the failure rate is also greatly reduced.

In the 1970s, Dr. joseph harrington first propoSMT machining sed the concept of cim (computer integrated manufacturing). Its connotation is to integrate all kinds of manufacturing-related technology systems in the enterprise with the help of computer, so as to improve the enterprise's ability to adapt to market competition. However, cims, a system based on the cim concept, began to gain attention and be implemented on a large scale in the mid-1980s. cims is database-centered and transmits the data in the design environment to each automatic processing equipment with the help of computer network, and can effectively control and supervise these automatic equipment. The connection between the production department and the design department can be established by using cims, which can be realized through the integration of cad/cam system. As mentioned above, many equipments in SMT line belong to automatic machining equipments controlled by computer, which makes it possible to construct cad/cam integrated system by computer aided manufacturing. In fact, most of the data required to program the machining equipment in the smt patch line can be obtained entirely from the relevant data files of the cad system. For example, the coordinate position of the component on the pcba, Angle, physical characteristic parameters, electrical parameters, etc. These data volume is large, some characteristic data is different processing equipment needs. Such as patch machine, dispensing machine, online testing equipment all need components on the pcb coordinate position. Therefore, using the philosophy and technology of cims, the cad/cam integrated system is established between cad and cam, and the corresponding characteristic data is extracted, sorted out/transformed and optimized directly from the data files of cad system, and according to the data format requirements of specific equipment programming or format requirements of n/c instruction through the computer network and interface communication software. It is transferred to the control computer of the machining equipment for direct invocation or direct drive of the CNC machining equipment during programming. Not only does this save data preparation and programming time, but also because of the direct.

Due to the characteristics of smt production, it is more appropriate to adopt jit for on-site management. By combining jit with tqc, waste can be reduced and product quality can be improved.