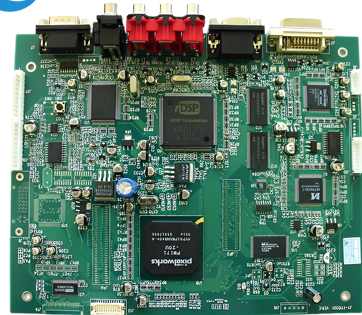

kinhford explains the rework process in PCBA

Rework is also called repair, but it is somewhat different from the repair in SMT patch processing. Let kinhford Electronic Technology Co., Ltd. introduce the rework process in PCBA: https://www.kingfordpcb.com/yuan.php?time=1685694568

https://www.kingfordpcb.com/yuan.php?time=1685694568

First, the difference between rework and maintenance

Rework generally refers to the reworking of nonconforming products by using the original SMT process or replacing the SMT process, and ensuring that the quality is in full conformity with the requirements of the drawings or technical specifications. Repair is the action of restoring the function of the defective product without ensuring that the repaired product conforms to the drawings or technical specifications.

Rework is not a standard process, basically the finished product for certain problems.

Ii. Rework process objectives

1. Controllable, reliable and repeatable process, which can be adjusted when necessary.

2. Efficient process, which can be carried out quickly and easily in the production environment.

3. Non-destructive process: In any rework process, PCB, adjacent components and components to be dismantled shall not be damaged.

Three, rework procedures

Rework includes replacement of components, including removal of components, arrangement of pads, installation of components three basic procedures, sometimes also need to consider the structural parts of electronic components, digital coating removal and replacement, etc. Simple operation: one-key measurement, easy to use, good stability, environmental protection material, use rest assured

2, accurate data: using filtering algorithm, accurate calculation of systolic and diastolic blood pressure values. 3, intelligent pressure: built-in 24-bit high-precision digital pressure sensor, accurately control the pressure pulse belt inflation and gas release, effectively eliminate the measurement of false error

4, voice broadcast: support volume adjustment, can be the whole automatic voice broadcast measurement results

5, large screen: the display is clearer, the algorithm has been tested a lot, more stable

6. Rich interface elements: real-time display of blood pressure value, high and low pressure warning, brightness adjustment and other user interface display effects can be realized

7, rechargeable: built-in rechargeable lithium battery, with Mini USB charging interface, easy to charge, no need to replace the battery

8, blood pressure measurement range: 0~ 299mmHg(0~ 39.9kPa), pulse measurement range (40~200 times/minute)

9, measurement accuracy: pressure accuracy ±3mmHg(± 0.4kPa) pulse accuracy ±5, automatic shutdown: 1 minute no operation automatic shutdown

The current design of this wrist sphygmomanometer solution, can provide the main control chip (IC), with the production materials of PCBA, or provide the module (PCBA), with complete operation instructions and technical solutions, to cooperate with the factory manufacturing. During the development process, the software and hardware can be modified, and the final test and sample delivery. If there is no problem, mass production and supply.

The above is about the "Runze Wuzhou for you detailed PCBA in the rework process" introduction, I hope to have some help to you, more PCBA information please pay attention to the content of the site update! kinhford Electronic Technology Co., Ltd. is a professional PCBA processing enterprise, with fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!