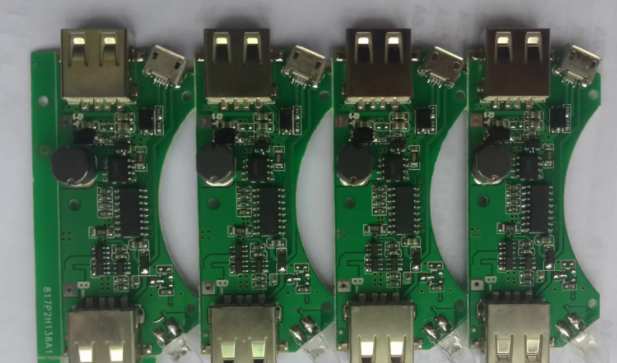

After pcb sampling, it is necessary to do a good job of inspection and take a look at the specific situation of these products. Many people do not do the inspection work properly, so it will directly affect the subsequent use. However, too many people do not consider the inspection matter in place, so it will affect the subsequent results. So in the process of doing what some inspection work can not be ignored?

Since we need to do the work of pcb proofing, we should check carefully after we finish the proofing, to see if there are some problems. Sometimes, if there are too many problems, it will affect the subsequent loss, and in the process of mass production, we will encounter more trouble, so we must have a very appropriate check for the specific situation in advance. Targeted to consider, after these aspects, then we can harvest better results.

While checking product quality, we should also take a look at some specific products after pcb proofing. Quality is very key, and we should also take a look at whether the product is in line with some of the original designs. Sometimes the product is not in line with the original design, which will directly affect the follow-up matters, so we can take these aspects into account in time and do the specific proofing work well. The result is much better.

It is very important for everyone to do a good job of inspection after pcb proofing. Many people do not do the inspection properly, and then when it enters mass production, there will be various problems in other aspects, which will bring great influence to us, and even directly lead to the subsequent use, which is not smooth. This will have a great impact on us, but also cause more serious, you have to understand these things to be particularly clear.

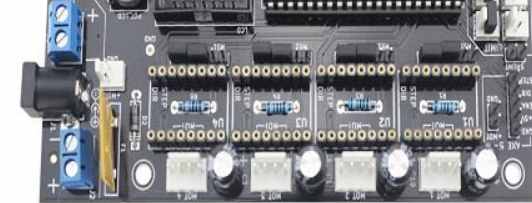

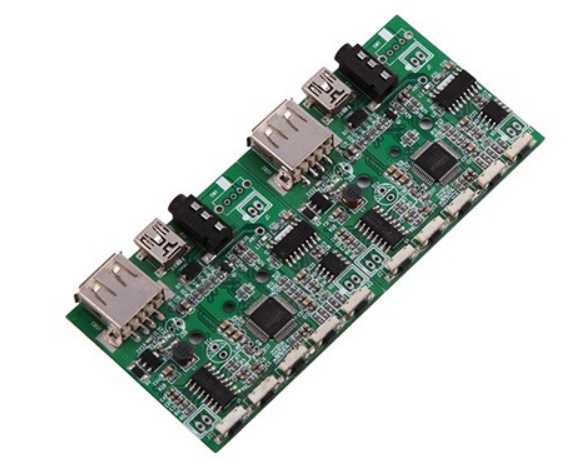

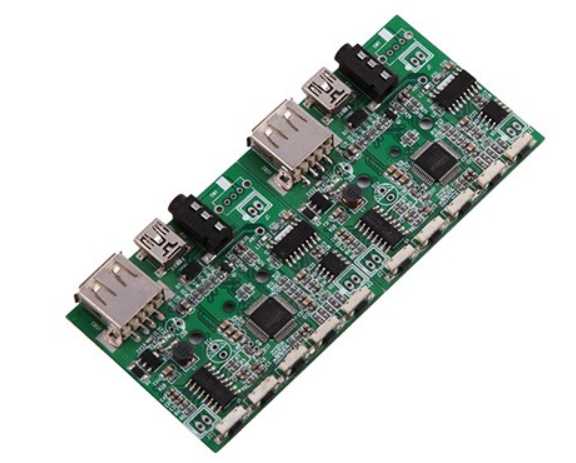

2. What costs will pcba OEM involve

Each industry has some aspects of the cost, many people will pay attention to some of the cost when doing pcba OEM, we can further analysis, and have a correct study of the cost of the problem, so as to be able to draw a more accurate conclusion.

What are some specific situations in the process of cost analysis? Let's do a further analysis now. From the aspect of specific cost, pcba OEM does involve some specific production technologies, because different technologies generally have certain differences in price, and we must take a look at the specific advantages of these technologies in the process of selection, and carefully study the specific situation of these aspects. After knowing these facts clearly, the choice made on this basis will become more accurate. Therefore, our analysis of technology will involve a lot of situations. If we can actively take into account these practical contents and have a more accurate understanding of technology, then we can be more secure.

Since we want to do pcba OEM, in fact, it also involves materials, and these costs of labor, of course, also includes specific equipment, some different production situations, the overall investment will also be affected by the complexity of the whole product, sometimes relatively complex, the need for funds will be more, if relatively simple, Therefore, we should timely take into account the actual situation in the selection process and have a correct understanding of some specific technical aspects, and then we can effectively avoid problems in other aspects.

From a correct point of view, we can better analyze the specific costs of these aspects of pcba OEM, and take into account the actual situation of all aspects. Only when people's analysis on the cost can become more accurate, can we effectively avoid some problems in other aspects. Therefore, in the process of making decisions, we should take into account the actual situation in time. The more accurate the analysis is, the more suitable it will be in the subsequent selection process.