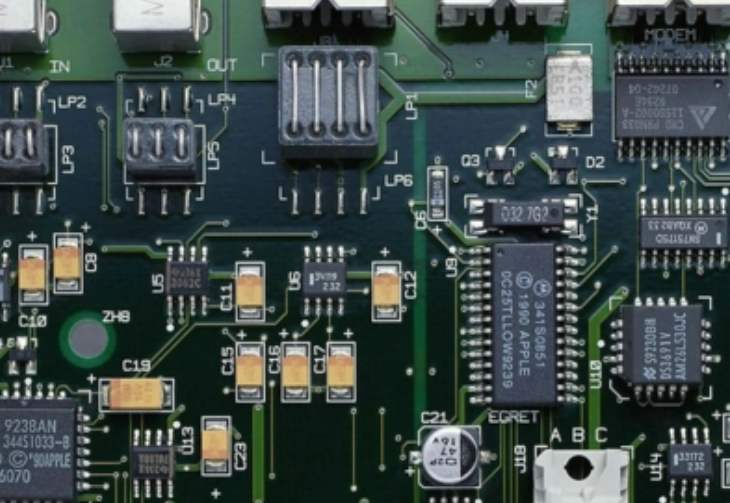

Printed circuit board (PCB), is a basic electronic component, widely used in a variety of electronic and related products. A PCB is also sometimes called a PWB (Printed Wire Board; in fact, there is a printed wire Board and a PWB).

PCB is the support body of electronic components, is the carrier of electrical connection of electronic components, mainly plays the role of support and interconnection. Purely from the appearance, the outer layer of the circuit board has three main colors: gold, silver, light red. By price: gold is the most expensive, silver is second, and light red is the least expensive. But the circuit board inside the line is mainly pure copper, that is, bare copper plate.

The PCB is also said to contain a number of precious metals. It is reported that the average smartphone contains 0.05g of gold, 0.26g of silver and 12.6g of copper. The gold content of a laptop computer is 10 times that of a mobile phone.

Why are there precious metals on the PCB?

PCB as the support body of electronic components, its surface needs to be welded components, it requires a part of the copper layer exposed for welding. These exposed layers of copper are called pad, pad is generally rectangular or circular, the area is very small, so brush on the solder resistance paint, the only exposure in the air is the copper on the pad.

Exposed pad on PCB, copper layer directly exposed. This part needs to be protected to prevent it from being oxidized.

The copper used in PCB is easy to be oxidized. If the copper on the pad is oxidized, it is not only difficult to weld, but also increases the resistivity, which seriously affects the performance of the final product. Therefore, the pad is plated with inert metal gold, or its surface is covered with a layer of silver by a chemical process, or a special chemical film is used to cover the copper layer, preventing the pad and air contact. Prevent oxidation, protect the pad, so that it in the following welding process to ensure yield.

Gold, silver and copper on PCB board

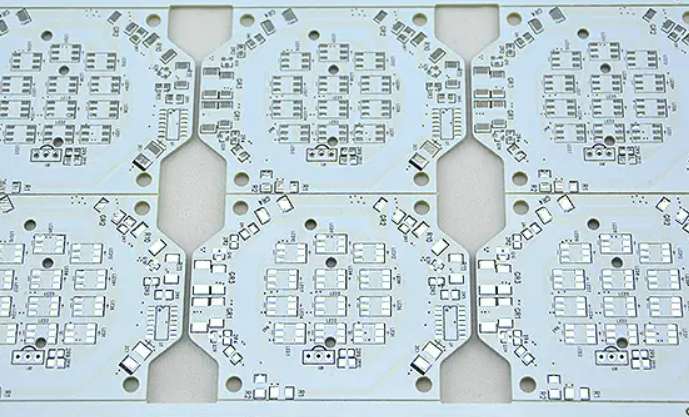

1. PCB copper-clad plate

Copper-clad sheet is a plate-like material made of glass fiber cloth or other reinforcing material impregnated with resin and covered with copper foil on one or both sides and pressed hot.

Take glass fiber cloth based copper clad plate as an example, its main raw materials are copper foil, glass fiber cloth, epoxy resin, accounting for about 32%, 29% and 26% of the product cost respectively.

Copper clad plate is the basic material of printed circuit board and printed circuit board is the main component of the vast majority of electronic products to achieve circuit interconnection indispensable. With the continuous improvement of scientific and technological level, in recent years, some special electronic copper clad plate can be used to directly manufacture printed electronic components. The conductors used in printed circuit boards are generally made of thin foil-like refined copper, that is, in the narrow sense of copper foil.

2, PCB sinking gold circuit board

Gold and copper direct contact will have the physical reaction of electron migration diffusion (potential difference), so must first electroplating a layer of "nickel" as a barrier layer, and then the gold plating to nickel above, so we generally called electroplating, its actual name should be called "nickel plating gold".

The difference between hard gold and soft gold is the composition of the last layer of gold plated. When gilded, you can choose to electroplate pure gold or alloy, because the hardness of pure gold is soft, so it is called "soft gold". Because "gold" and "aluminum" form a good alloy, so COB when aluminum wire will be specific to the thickness of this layer of pure gold. In addition, if you choose electroplated nickel alloy or gold-cobalt alloy, because the alloy will be harder than pure gold, so it is called "hard gold."

Gold coating is widely used in PCB circuit board components welding pad, gold finger, connector shrapnel and other positions. The most widely used mobile phone circuit board motherboard is mostly gold plate, gold plate, computer motherboard, audio and small digital circuit board are generally not gold plate.

Gold is real gold. Even a thin coating can account for nearly 10% of the board's cost. The use of gold as a coating, one is to facilitate welding, two is to prevent corrosion. Even the gold finger of a memory that has been used for several years is still shining. If copper, aluminum and iron are used, they can rust into a pile of junk quickly. In addition, the cost of gold-plated plate is high, welding strength is poor, because the use of nickel plating process, easy to have black disk problems. The nickel layer oxidizes over time, and long-term reliability is also an issue.

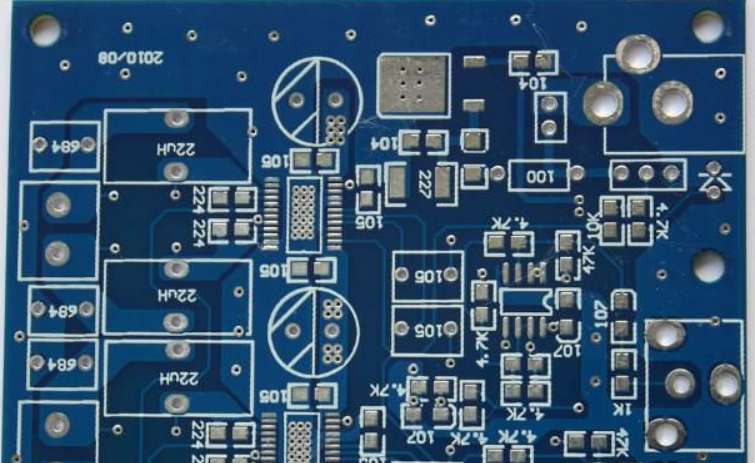

3, PCB silver circuit board

Silver sinking is cheaper than gold sinking, if the PCB board has connection functional requirements and needs to reduce costs, silver sinking is a good choice; Plus silver sinking good flatness and contact, it should be more choose silver sinking process.

It is widely used in communication products, automobiles and computer peripherals. It is also used in high-speed signal design. It can also be used in high frequency signals because it has excellent electrical properties unmatched by other surface treatments. EMS recommends the silver sinking process because it is easy to assemble and has good inspectability. But it grows slowly (but does not decline) because of defects such as tarnish and holes in solder joints.